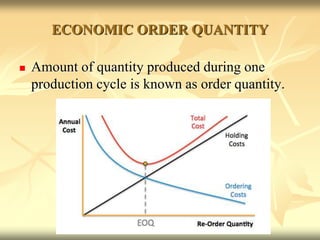

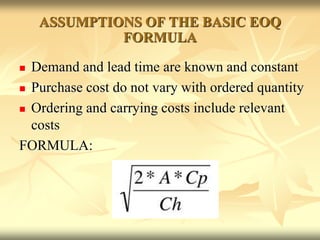

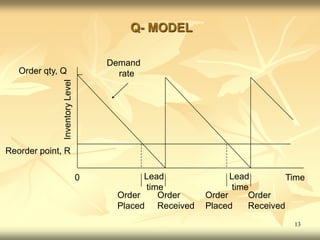

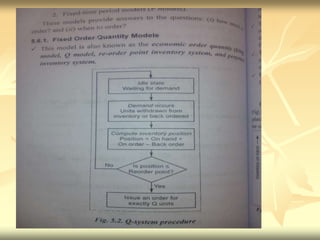

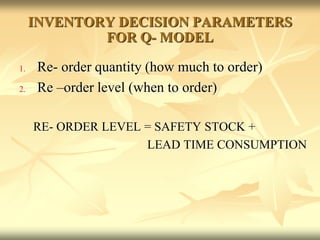

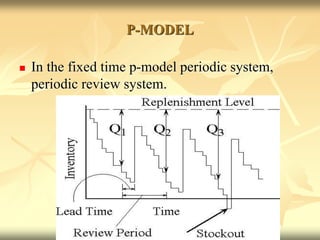

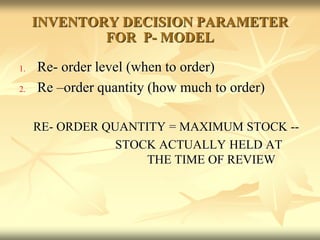

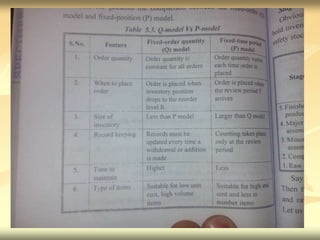

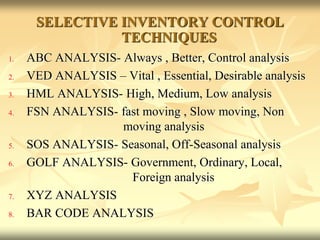

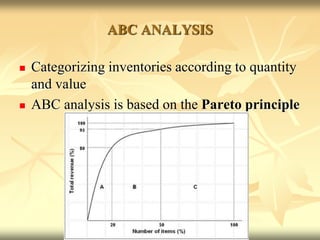

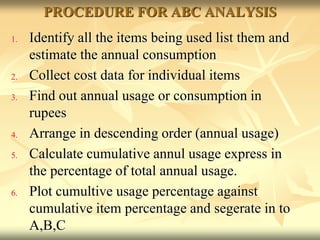

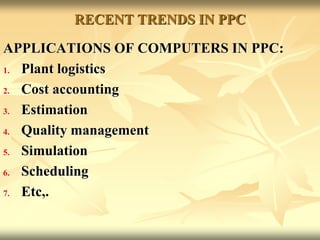

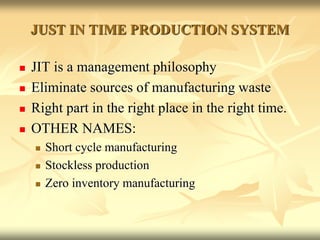

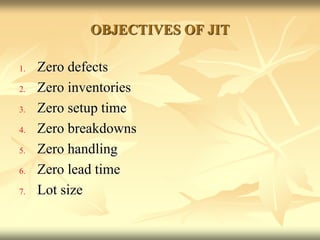

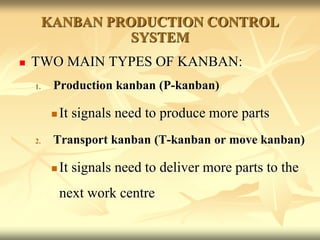

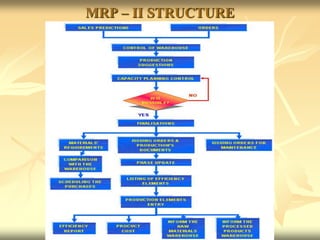

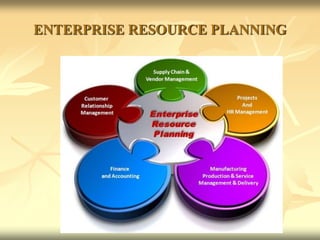

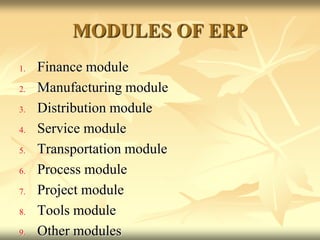

This document discusses inventory control and recent trends in production planning and control (PPC). It defines inventory and different types of inventory classified based on material flow and nature of use. It also discusses the purpose of holding stock, inventory control including economic order quantity model, and inventory decision parameters for Q and P models. Recent trends covered include applications of computers in PPC, computerized PPC systems, just-in-time production, kanban production control, manufacturing resource planning (MRP II), enterprise resource planning (ERP) and its modules.