The document discusses supply chain management in the internet age. It covers several topics:

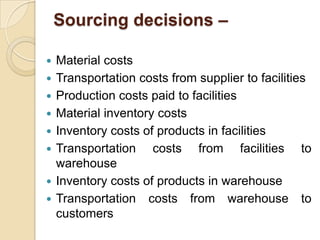

- Supply chain management (SCM) coordinates players in the supply chain to deliver the right products at the right time, place, and price. Effective SCM reduces costs and improves customer satisfaction.

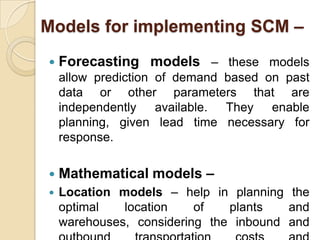

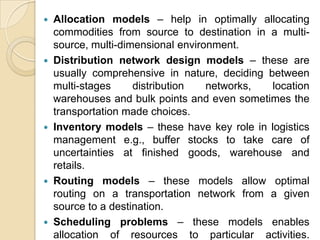

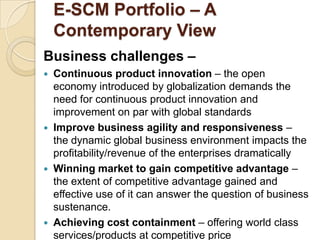

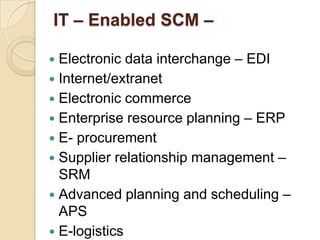

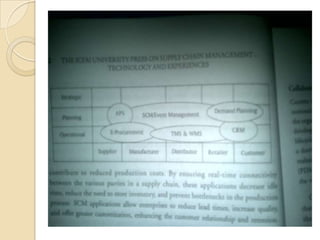

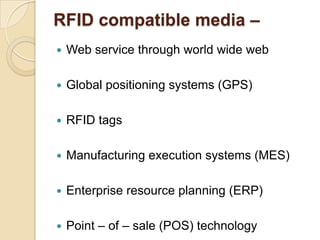

- Electronic SCM (e-SCM) uses software and internet technologies to improve planning, execution, warehousing, and transportation management across the supply chain.

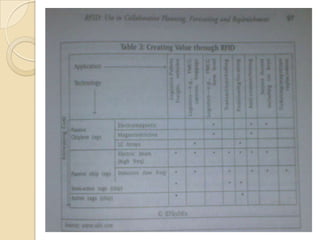

- Radio frequency identification (RFID) provides benefits like advanced shipping notices but faces challenges in data storage, integration, and configuration.

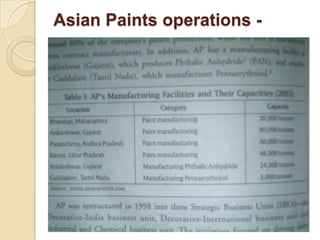

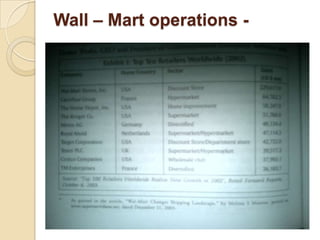

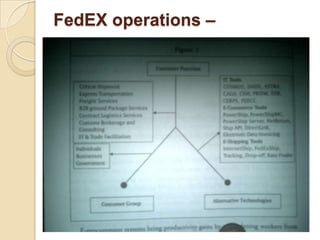

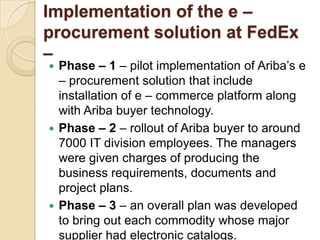

- Various companies implement different SCM strategies using IT and the internet. For example, FedEx implemented e-procurement in phases, rolling it