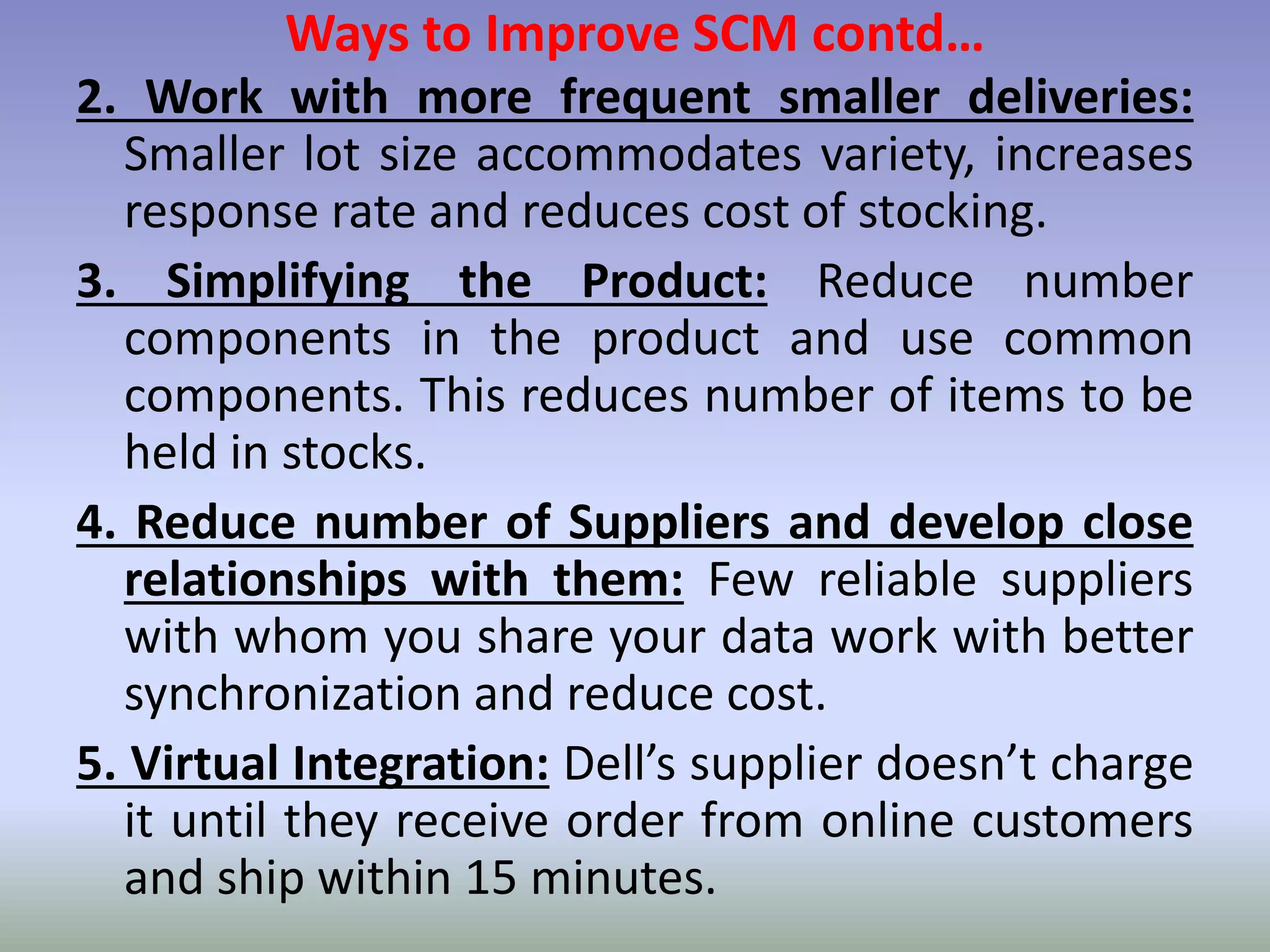

Supply chain management involves the flow of goods from raw materials to finished products and distribution to customers. It includes activities like product development, procurement, manufacturing, distribution, and after-market support. Companies are both suppliers and customers in the supply chain network. The objective of supply chain management is to satisfy customers while keeping costs low. It requires coordination between the different links to deal with challenges like increased outsourcing, shorter lead times, globalization, and shortened product cycles. Improving supply chain performance can be done through faster order communication, transportation, working with smaller and more frequent deliveries, simplifying products, reducing the number of suppliers, and virtual integration between links.