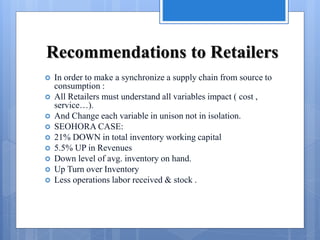

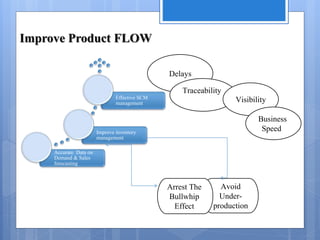

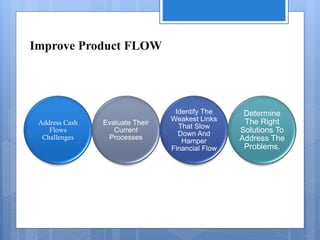

The document outlines the benefits of supply chain management (SCM) including optimizing product, information, and financial flows to create market opportunities, lower costs, and enable quicker decision-making. It discusses how effective SCM can improve product flows through reduced delivery times and improved inventory management. It also explains how SCM provides seamless information and financial flows through enhanced collaboration, visibility, and addressing cash flow challenges. The document recommends that companies embrace a data-driven SCM approach using integration and data management to maximize benefits.