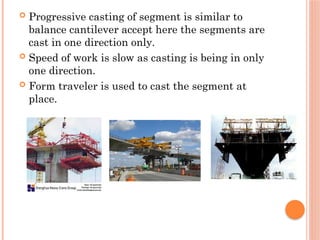

The document discusses various bridge construction methods, focusing on segmental and full span construction techniques. It outlines the advantages and challenges of methods such as span by span, balance cantilever, and progressive placement, highlighting their suitability based on project requirements and structural constraints. Additionally, it compares precast and cast-in-place techniques, noting that precast methods are generally preferred for their quality, while cast-in-place is used when logistical barriers exist.