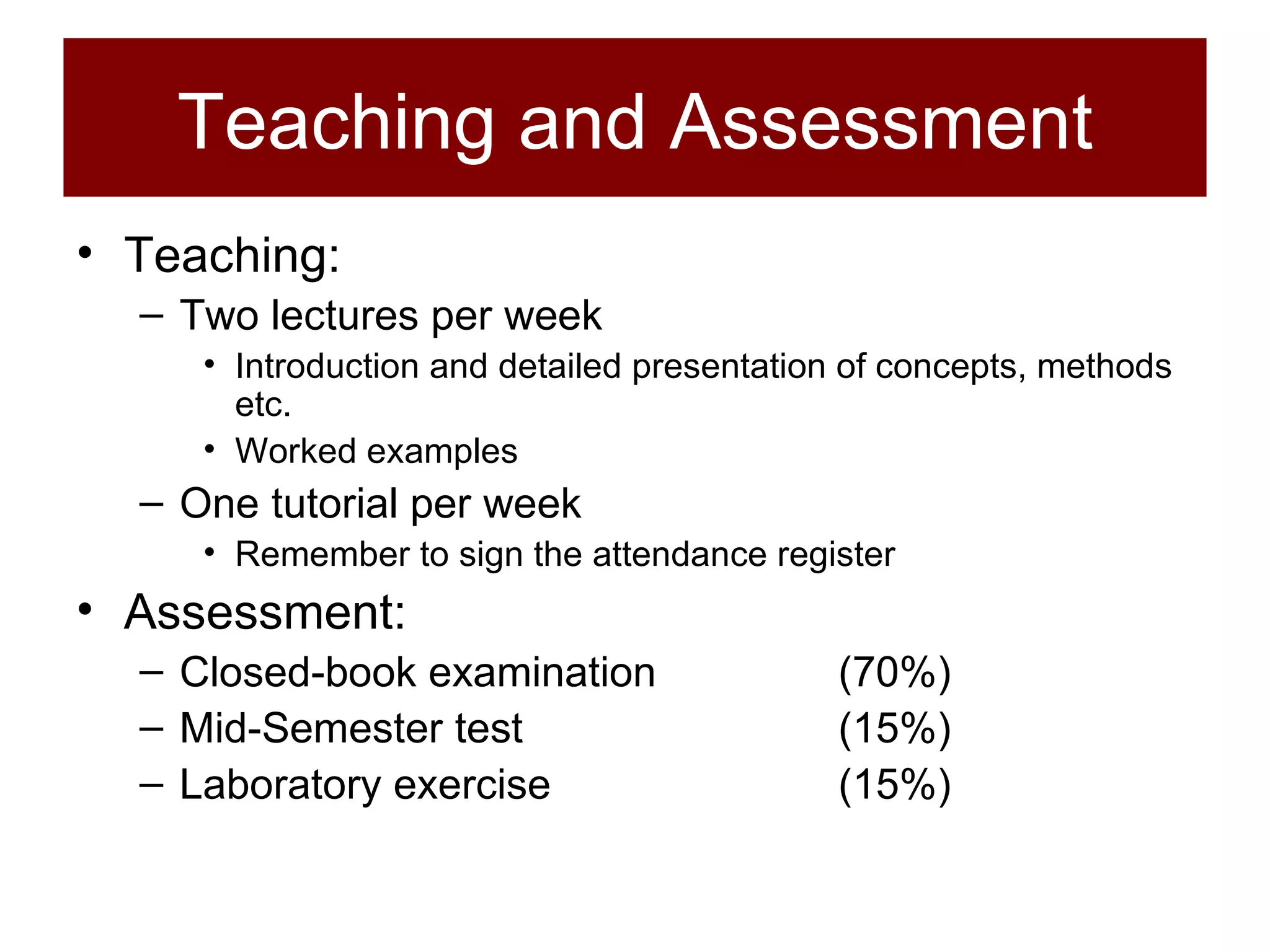

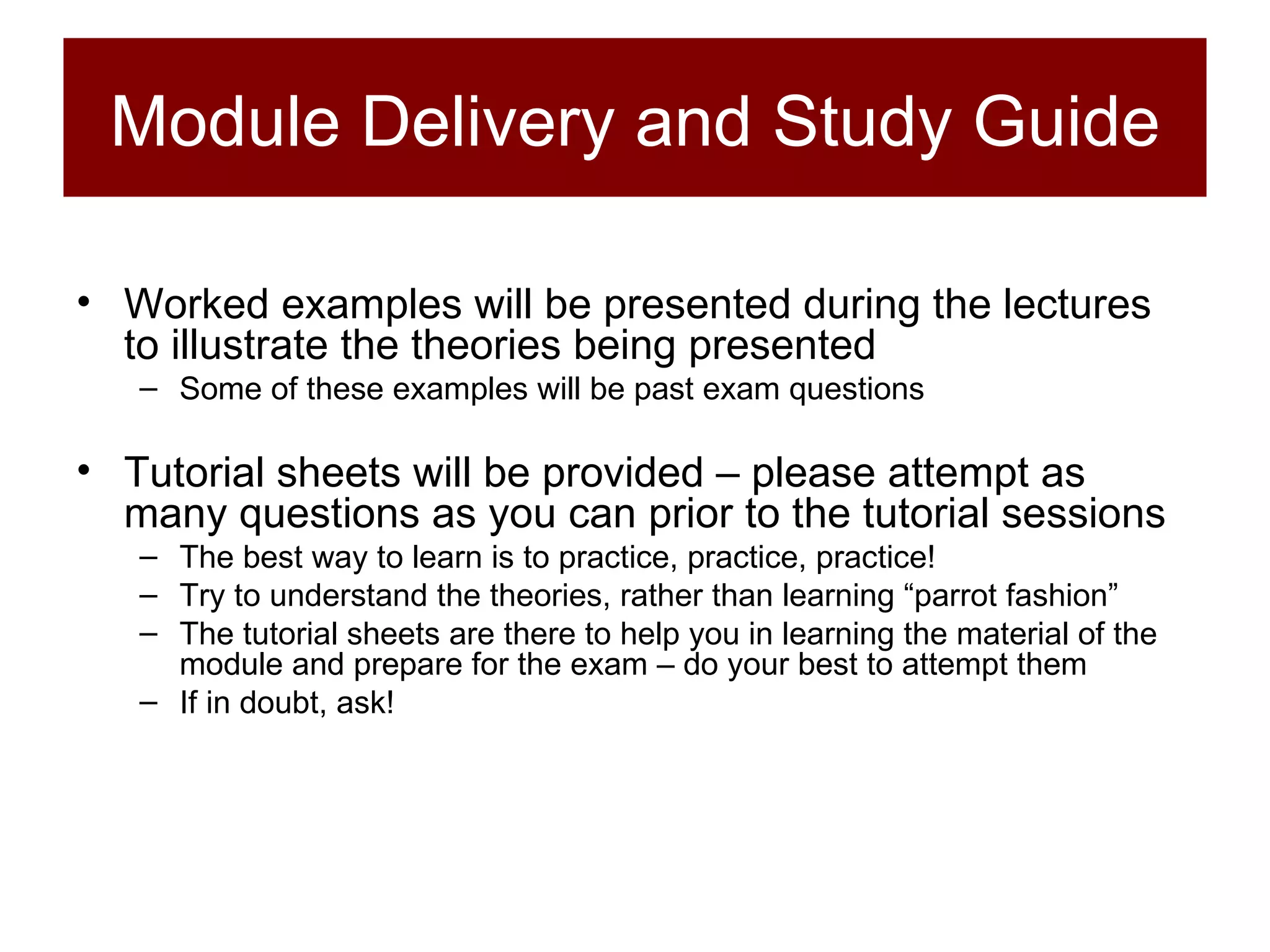

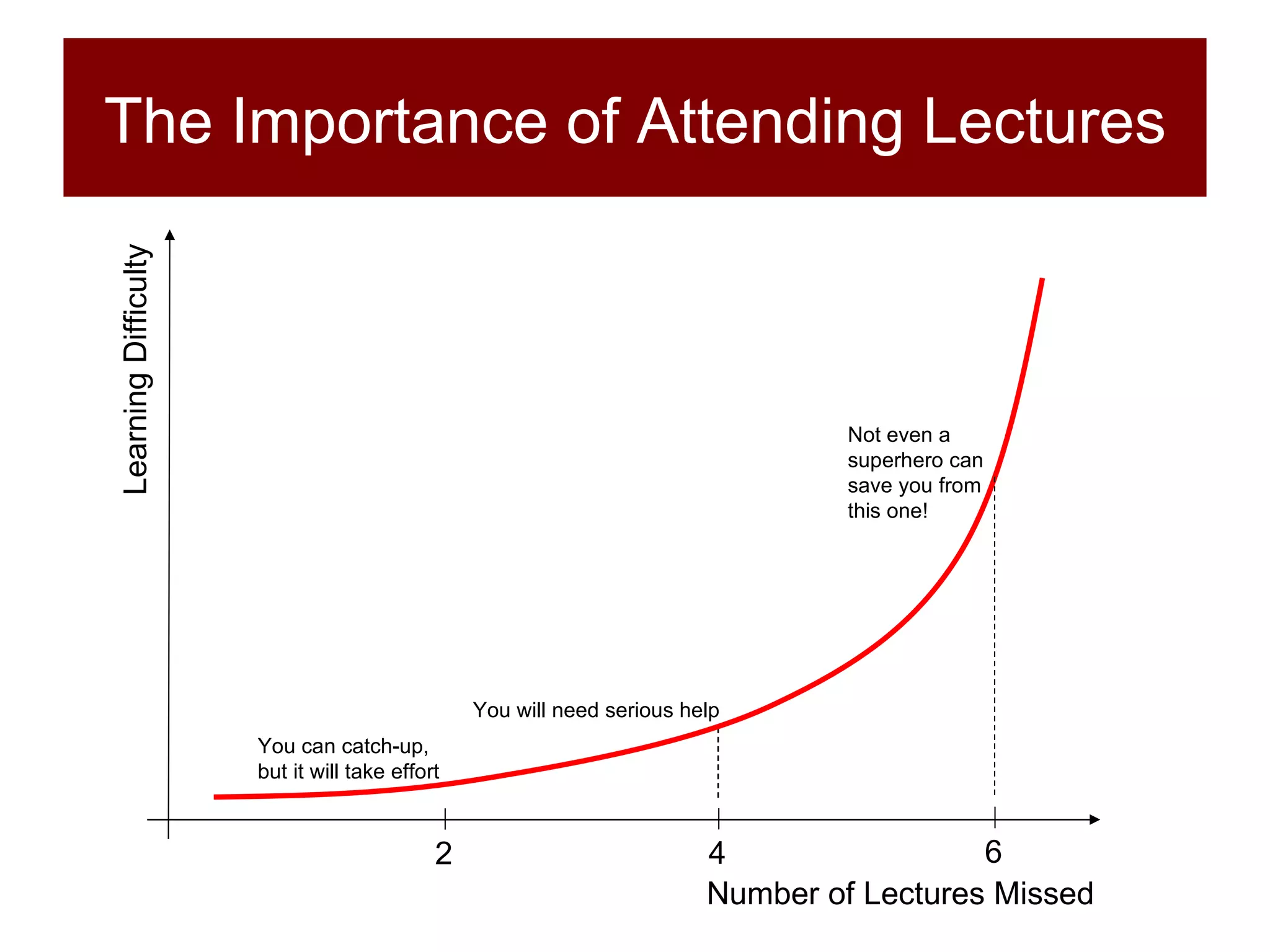

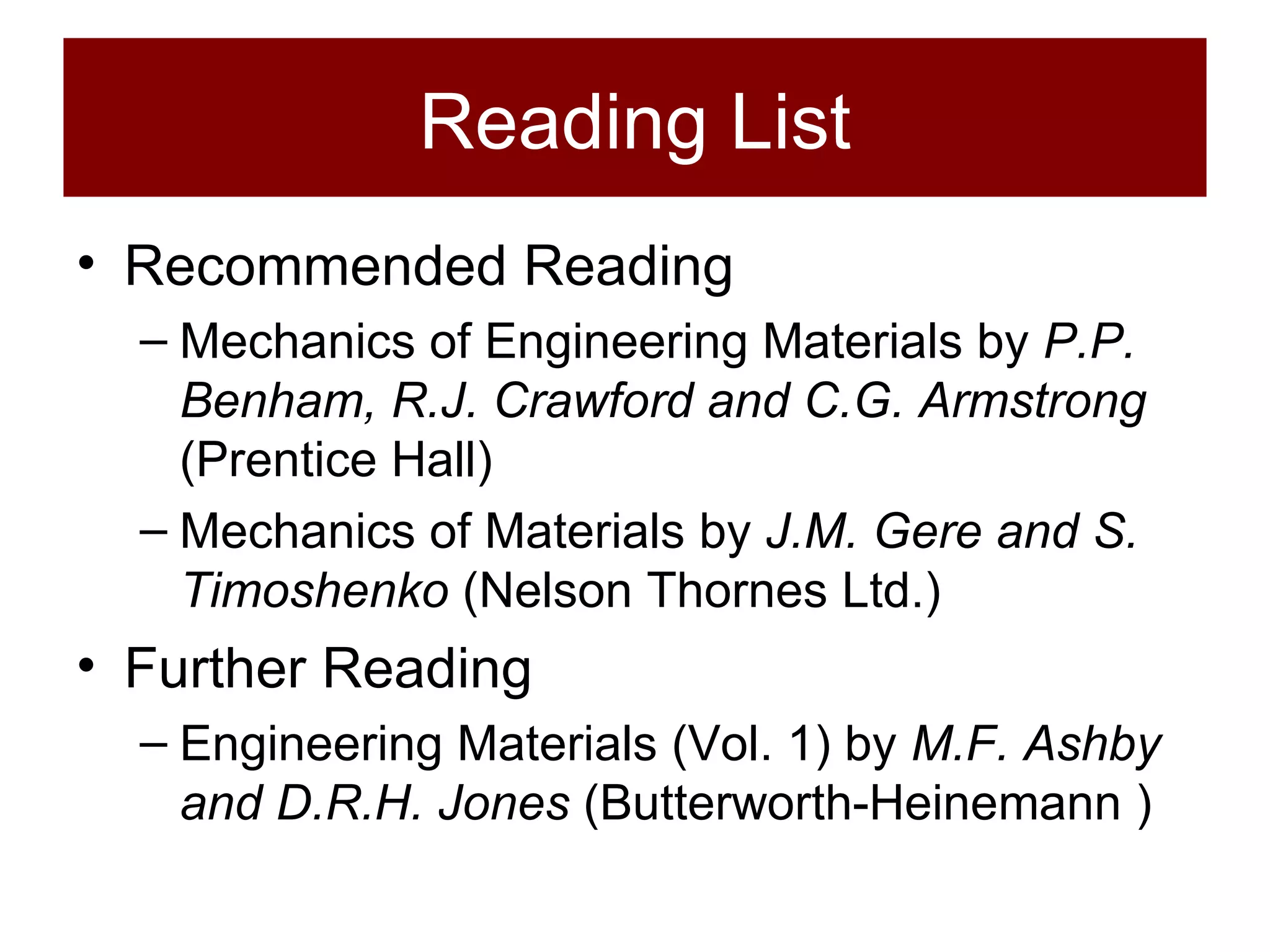

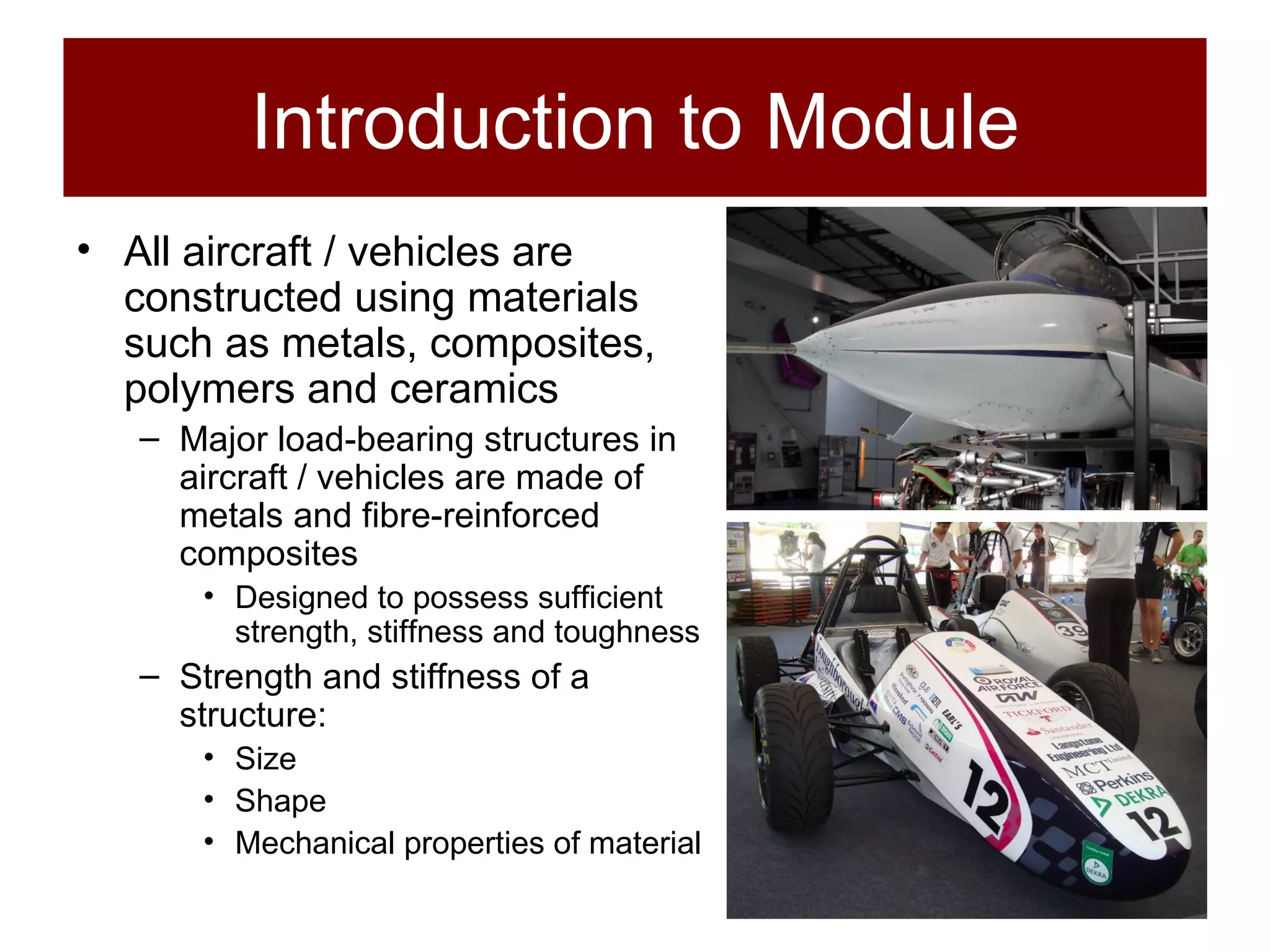

The module focuses on the analysis and design of structural components under tension, compression, and shear, highlighting essential concepts and methodologies. It includes aims, intended learning outcomes, teaching methods, and assessment details, emphasizing the importance of lectures and practical exercises. Key topics cover material properties, equilibrium conditions, and stress-strain relationships within structural engineering.