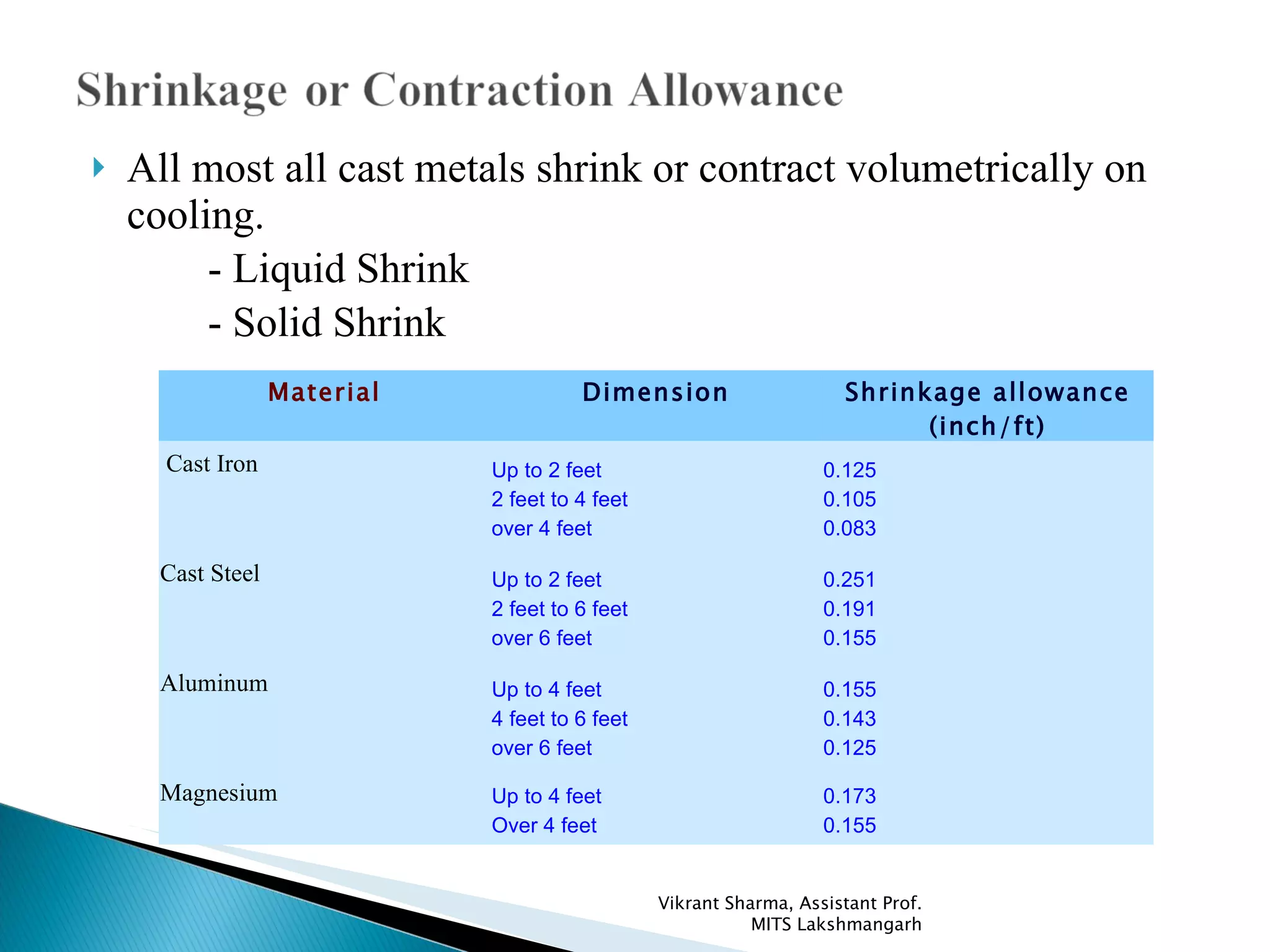

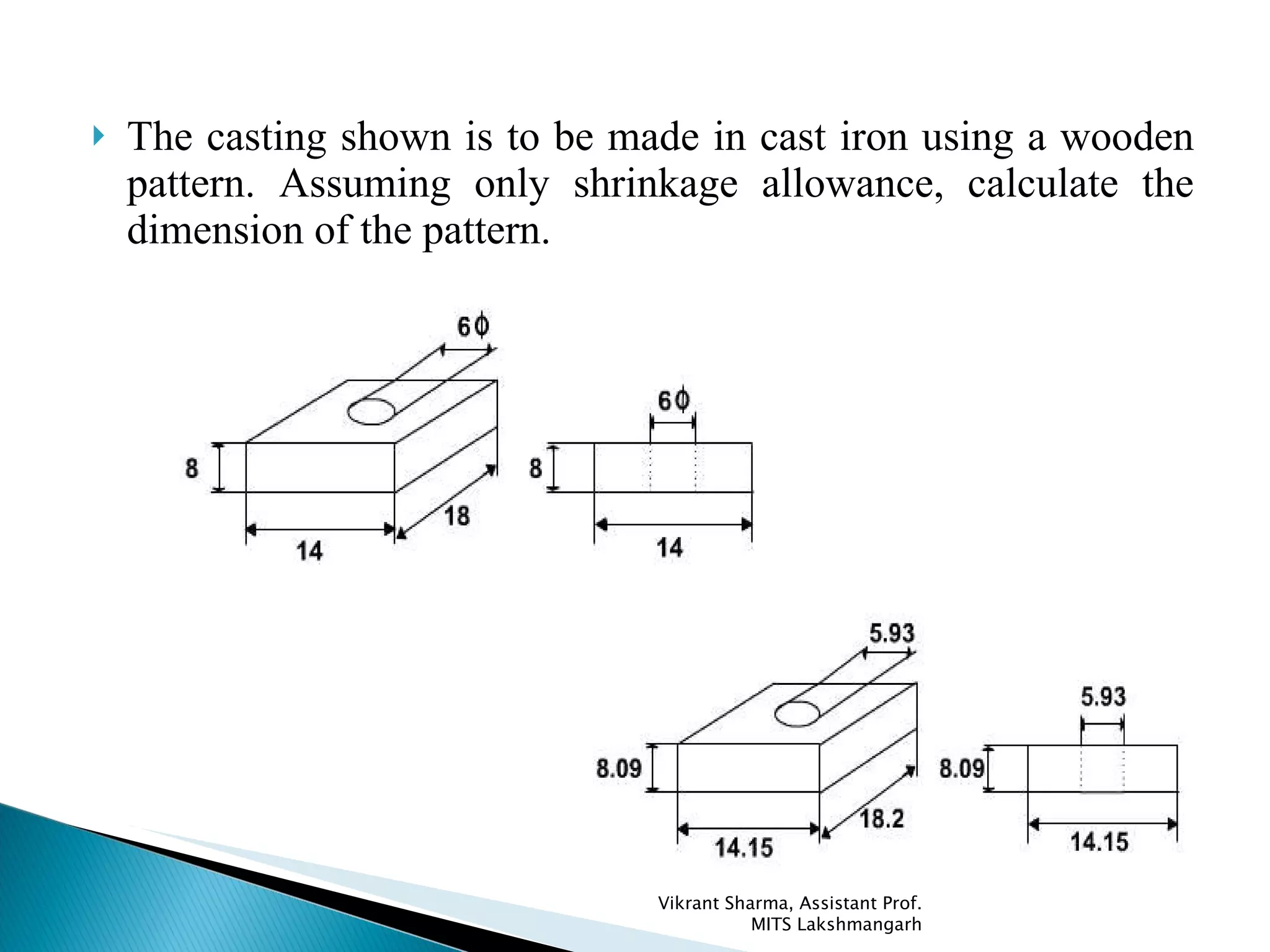

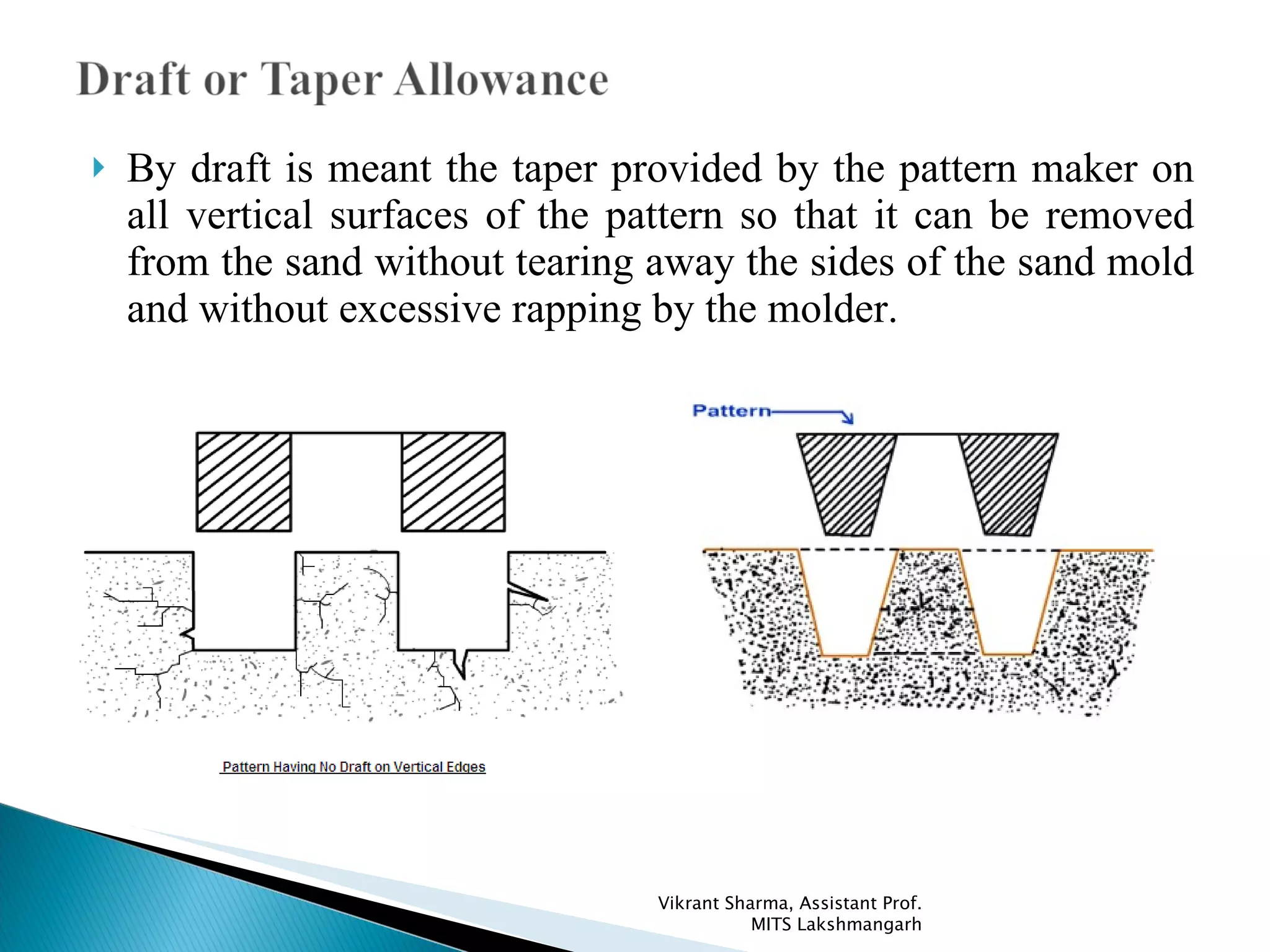

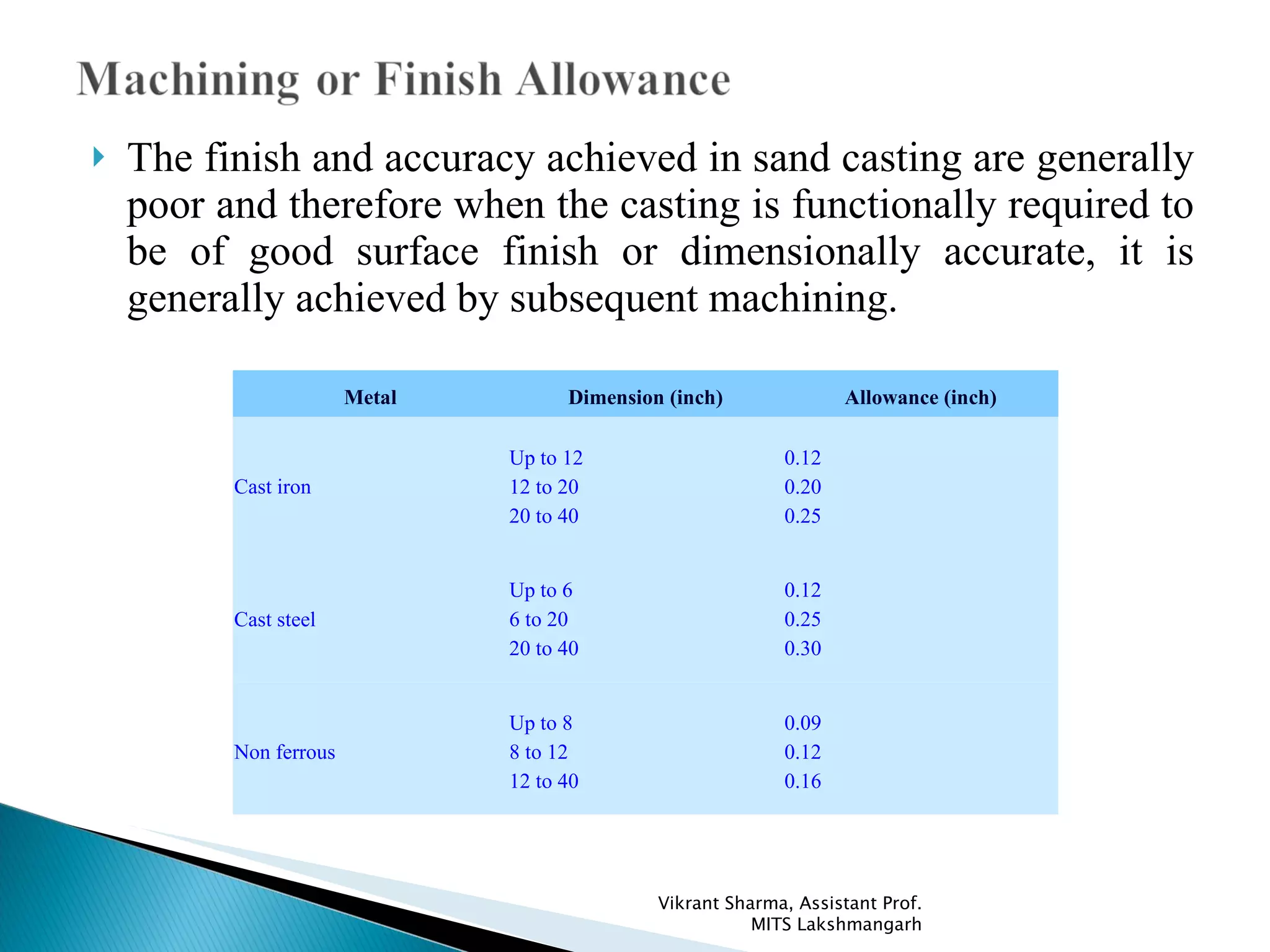

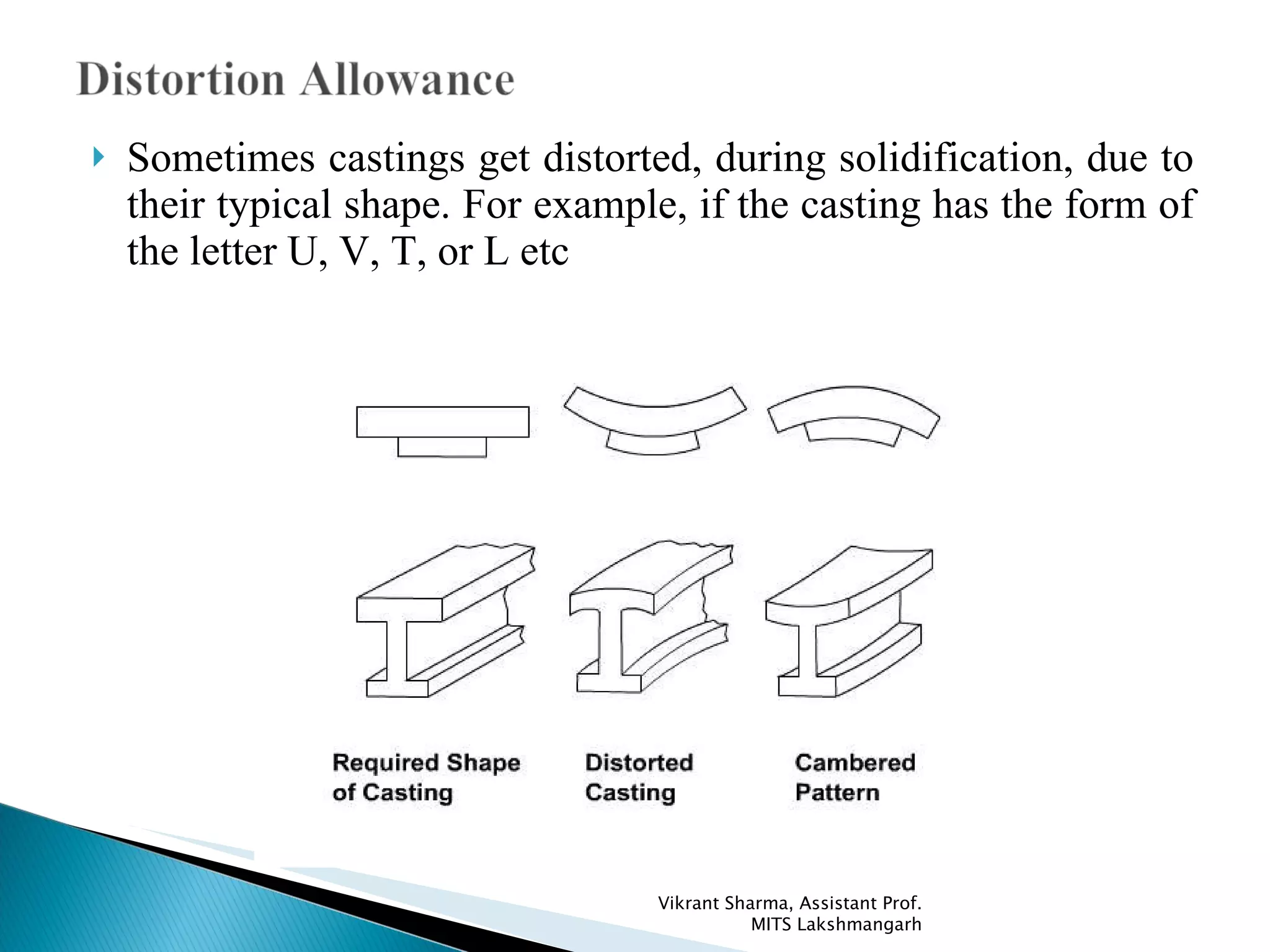

The document discusses various types of allowances that must be made when designing patterns for sand casting, including shrinkage allowance to account for metal contraction during cooling, draft allowance to facilitate pattern removal from molds, machining allowance for parts requiring high dimensional accuracy or surface finish, distortion allowance for parts prone to warping, and rapping allowance to account for mold cavity enlargement during pattern removal. It provides tables of typical shrinkage allowances by material and dimension, machining allowances by material and dimension, and explains how to calculate pattern dimensions when only shrinkage allowance is considered.