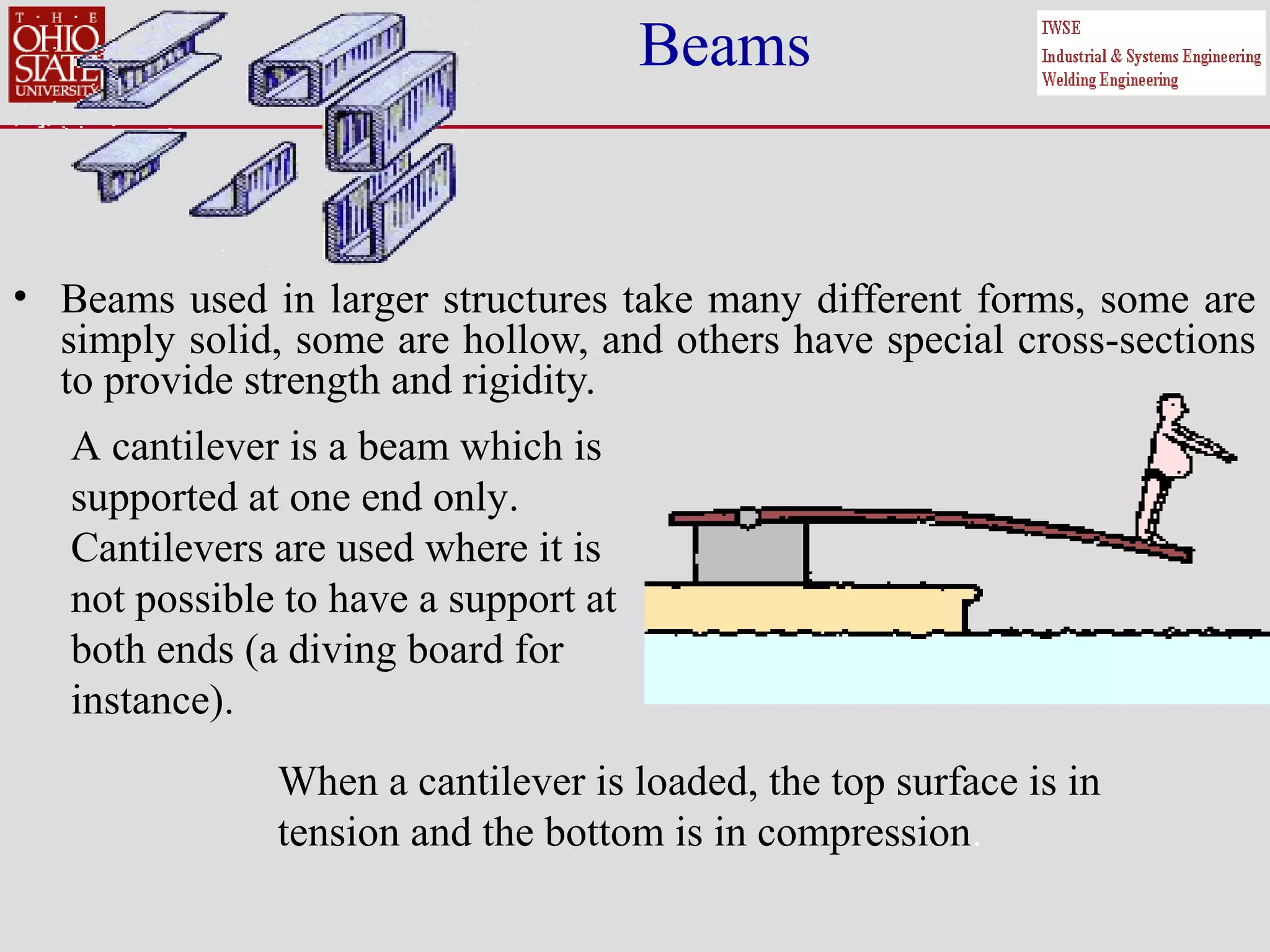

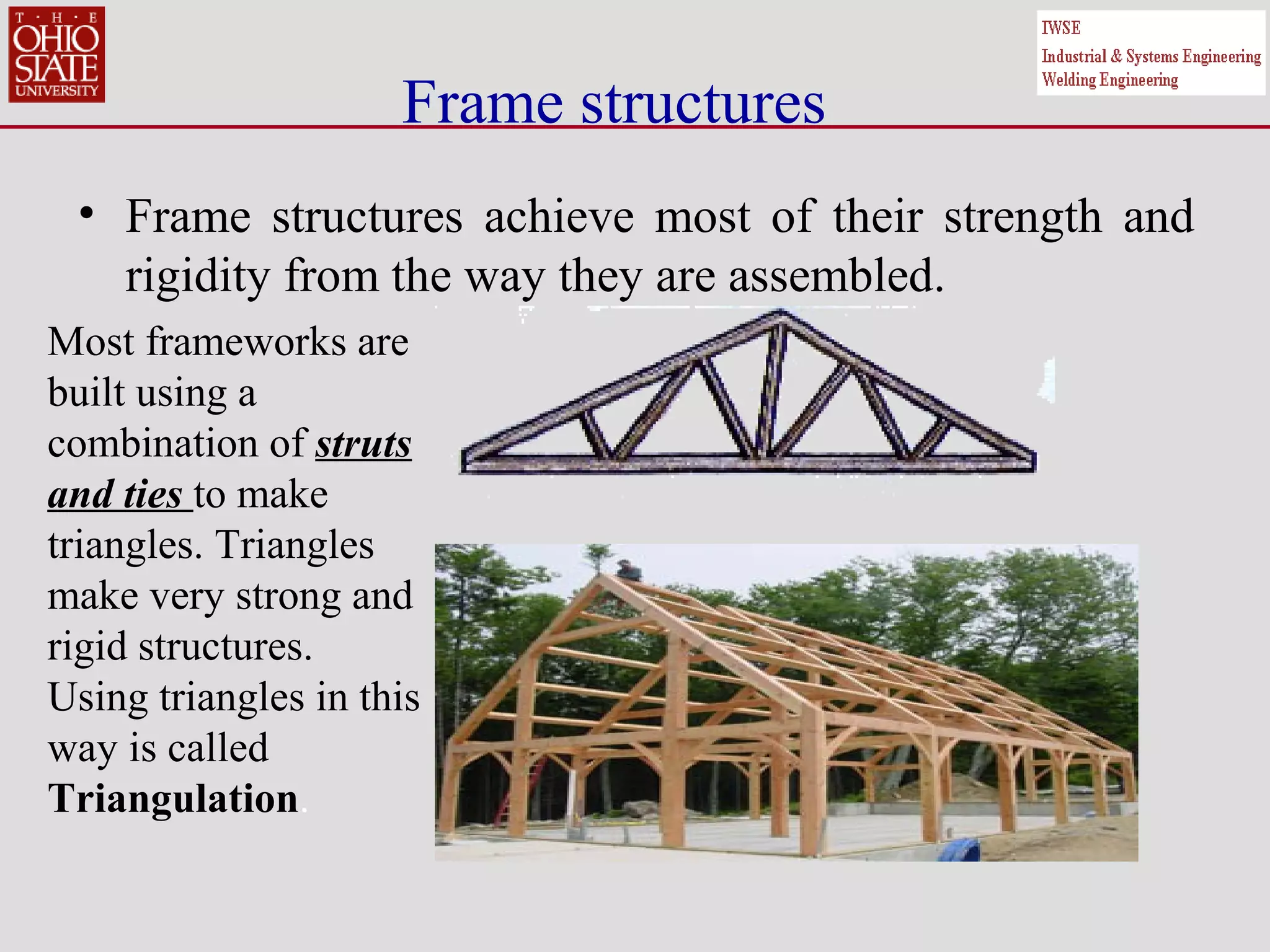

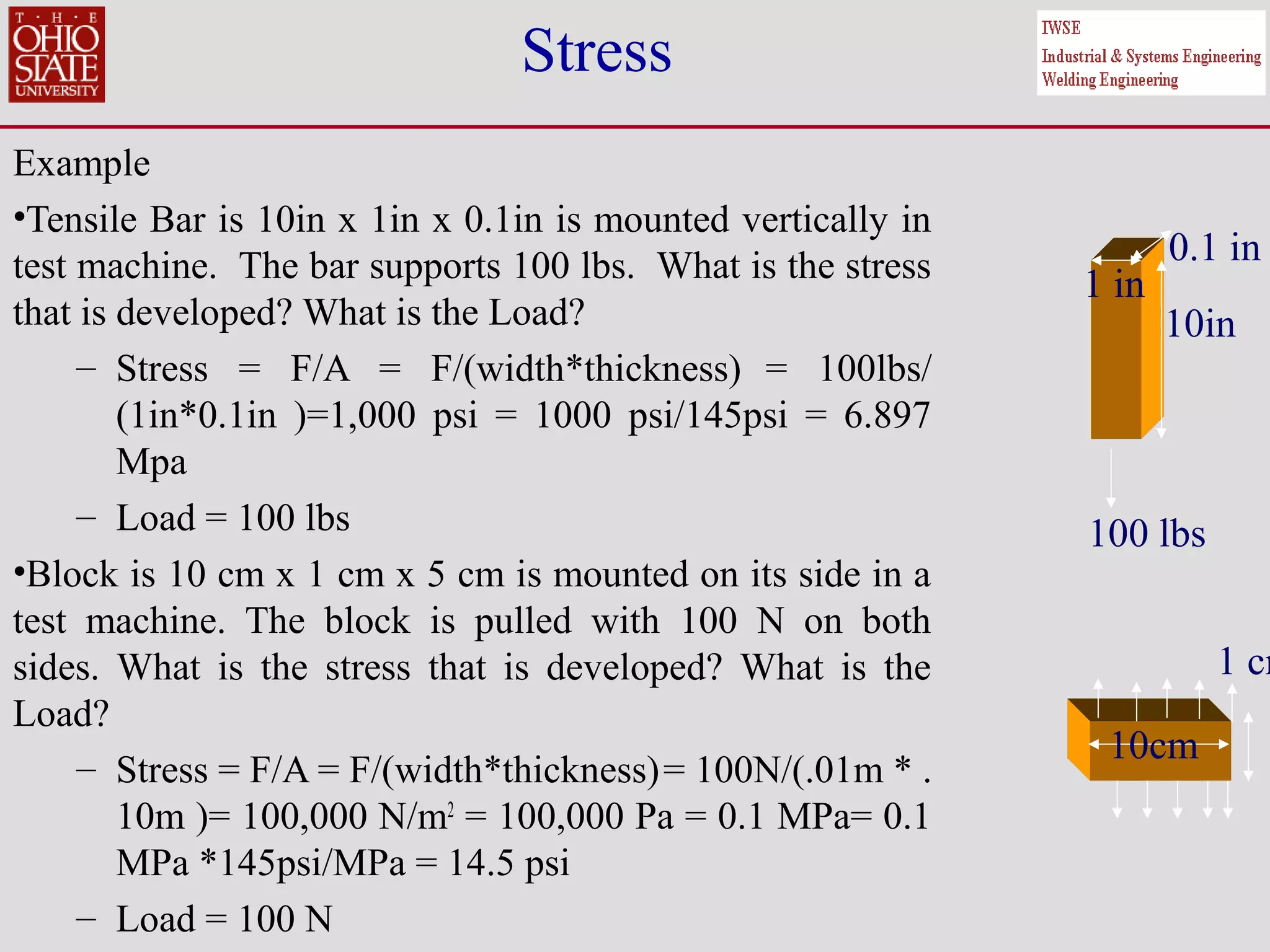

A structure is anything that supports a load. There are three main types of structures: mass structures, which rely on their own weight to resist loads; frame structures, made of connected parts like members; and shell structures, made from thin sheet material molded into shapes. Structures must withstand various forces, both internal forces between parts and external forces from outside. Forces can be tensile (pulling), compressive (pushing), torsional (twisting), or cause bending or shearing. The way a material responds to forces depends on its mechanical properties like strength, stiffness, and whether it behaves elastically or plastically.