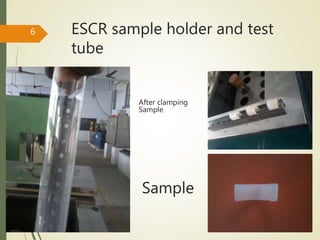

This document discusses environmental stress cracking resistance (ESCR) testing of thermoplastic polymers. ESCR is one of the most common causes of unexpected brittle failure in plastics. The rate of ESCR depends on factors like a polymer's chemical makeup, molecular weight, and residual stress as well as the liquid's chemistry, temperature, and strain rate. The document describes an ESCR testing machine and procedure where samples are clamped and submerged in a detergent solution at elevated temperature for 30 minutes before being examined for surface cracks. The test determines a material's resistance to environmental stresses.