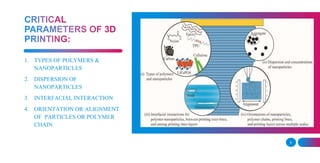

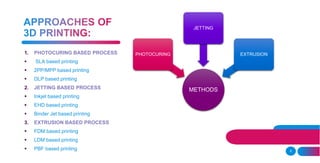

The document discusses three-dimensional printing (3D printing) technology, highlighting its transformative potential in various fields, especially healthcare, due to recent FDA approvals and advancements. It covers different 3D printing methods, including SLA, DLP, and FDM, and their applications in rapid prototyping, personalized medicine, and drug delivery. The benefits of 3D printing include cost efficiency, customization, complex fabrication capabilities, and innovative dosage forms, which are set to revolutionize the pharmaceutical industry.