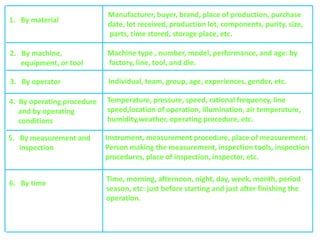

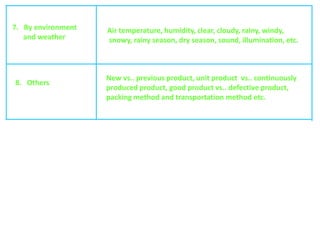

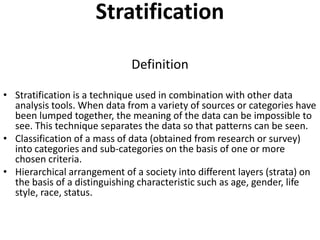

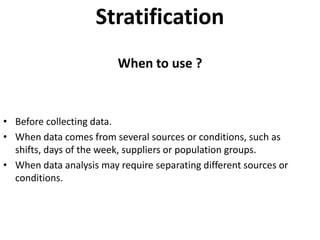

1. The document discusses the problem solving technique of stratification. Stratification involves separating collected data into categories based on characteristics like source, equipment, operator, or time period.

2. Stratifying data makes patterns more visible by distinguishing different data subsets. It allows analyzing the effects of different sources or conditions separately.

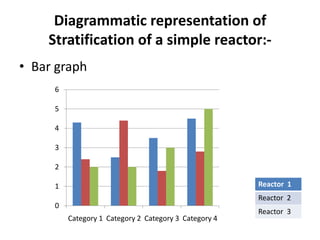

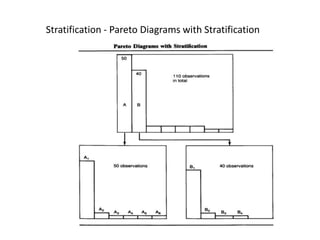

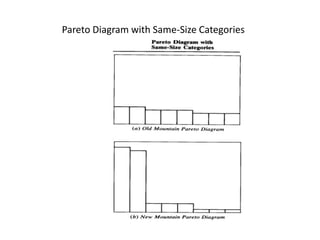

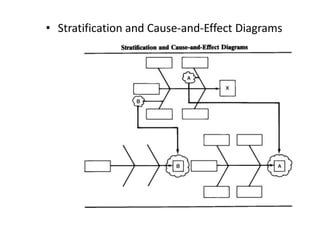

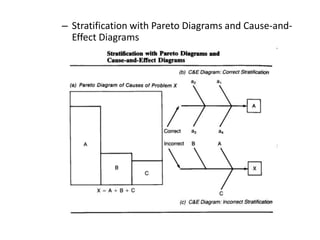

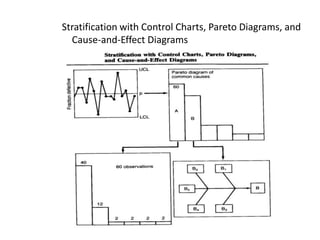

3. The document provides examples of how to stratify data on various charts and diagrams to better identify relationships and variations among strata for problem analysis and solution.

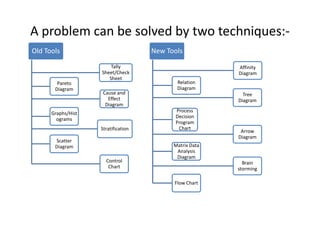

![Stratification

Method

To sum up

Usage Result

Grouping by •Used to observe variations

•Allows observation

day, time, place, wo among strata.

of variations among

rker, or process •Used to identify the

strata.

relationship between cause

•By performing a

Number of Units

and effect.

cause analysis using

X ★★★★★★★ •Used to identify a purpose

the stratified

Y △△△△ and means to serve the

data, the following

purpose

Z ○○○

[Used during phases to monitor

can be accomplished.

the situation, analyze 1.Identification and control of a

causes, review effectiveness of an problem

action, perform 2.“Division of data (obtained by

standardization, and implement a using each QC tool) into several

selected control measure.] groups”

17](https://image.slidesharecdn.com/stratificationanshul-121204063020-phpapp02/85/Stratification-anshul-17-320.jpg)