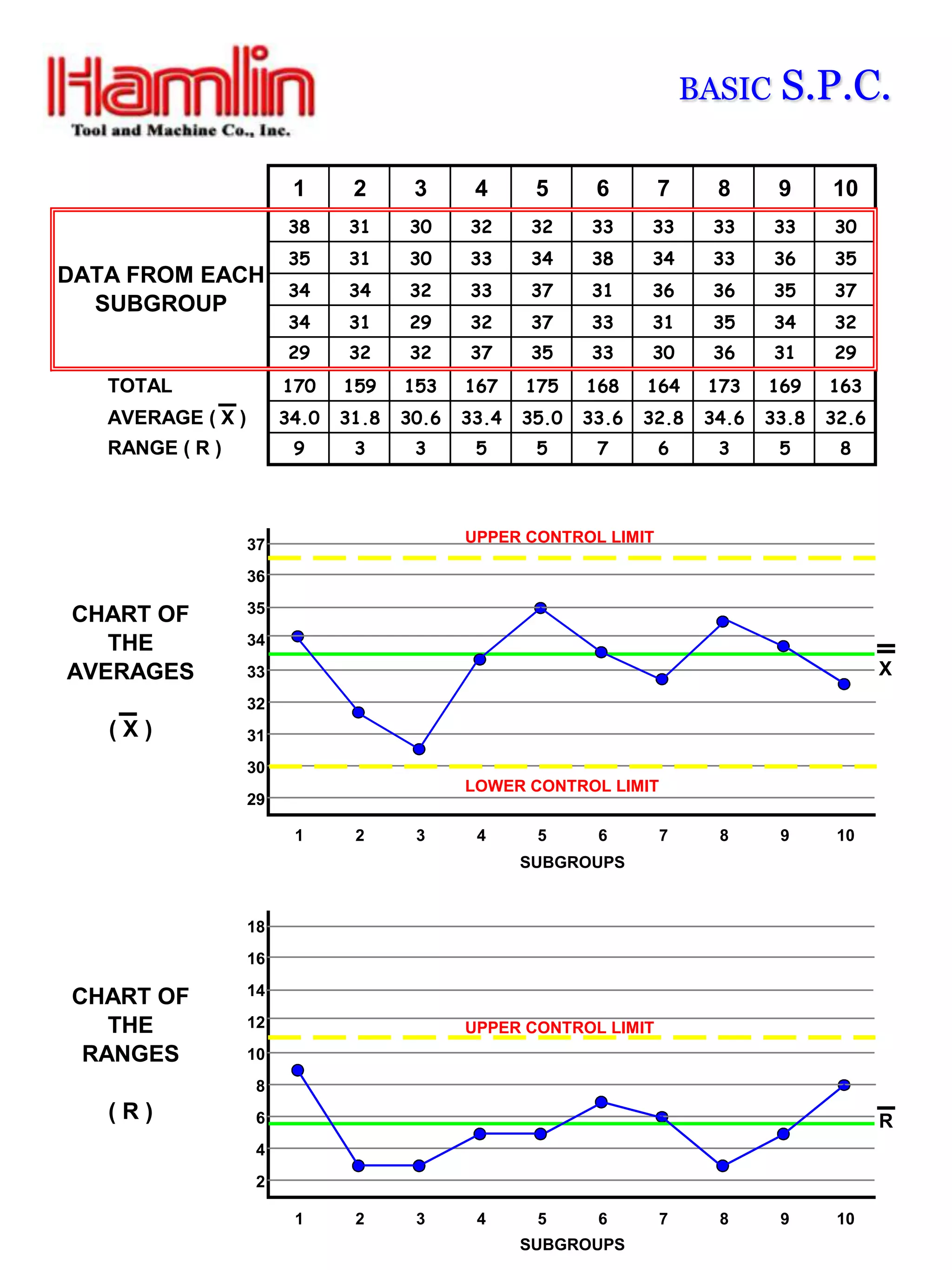

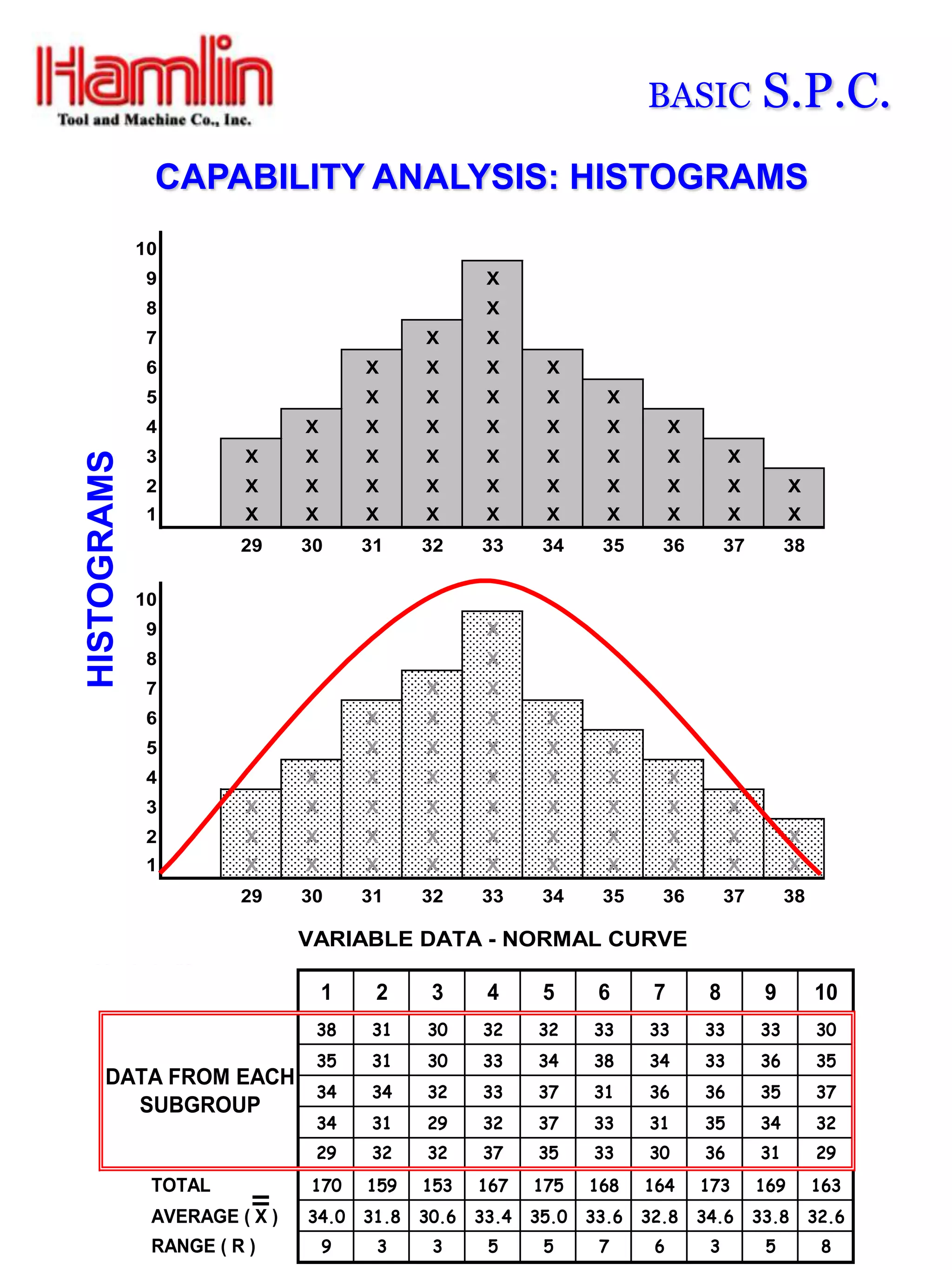

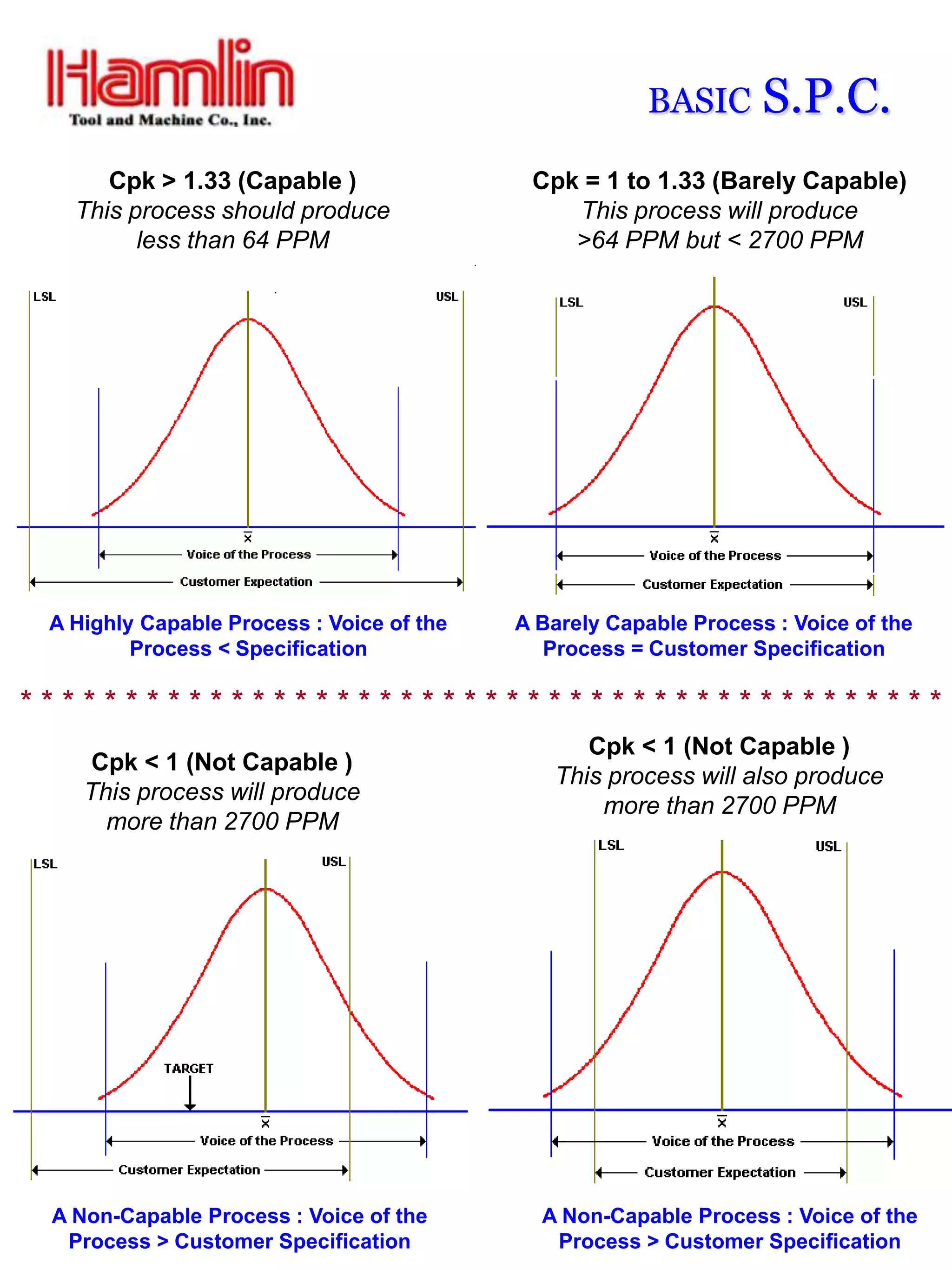

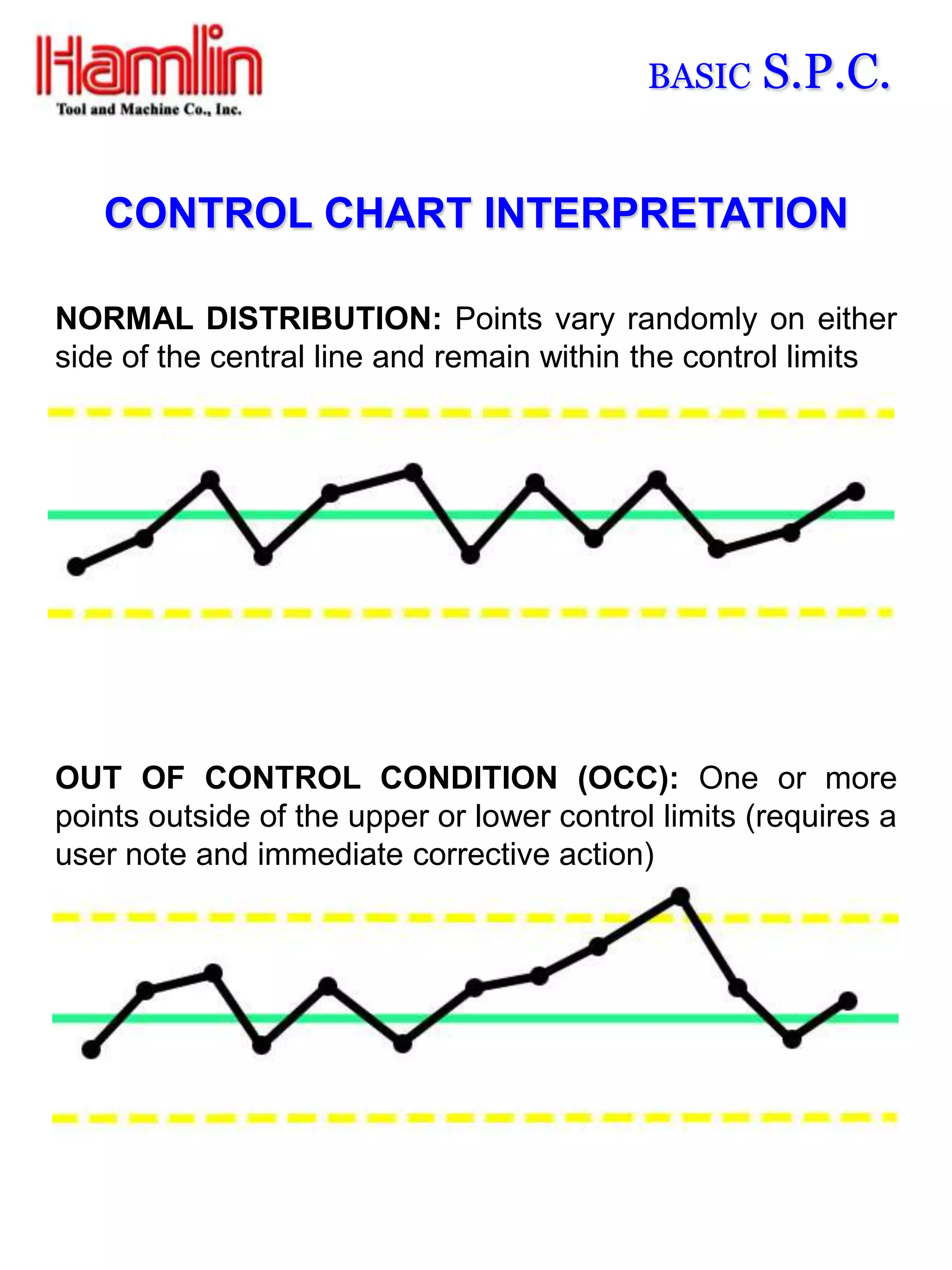

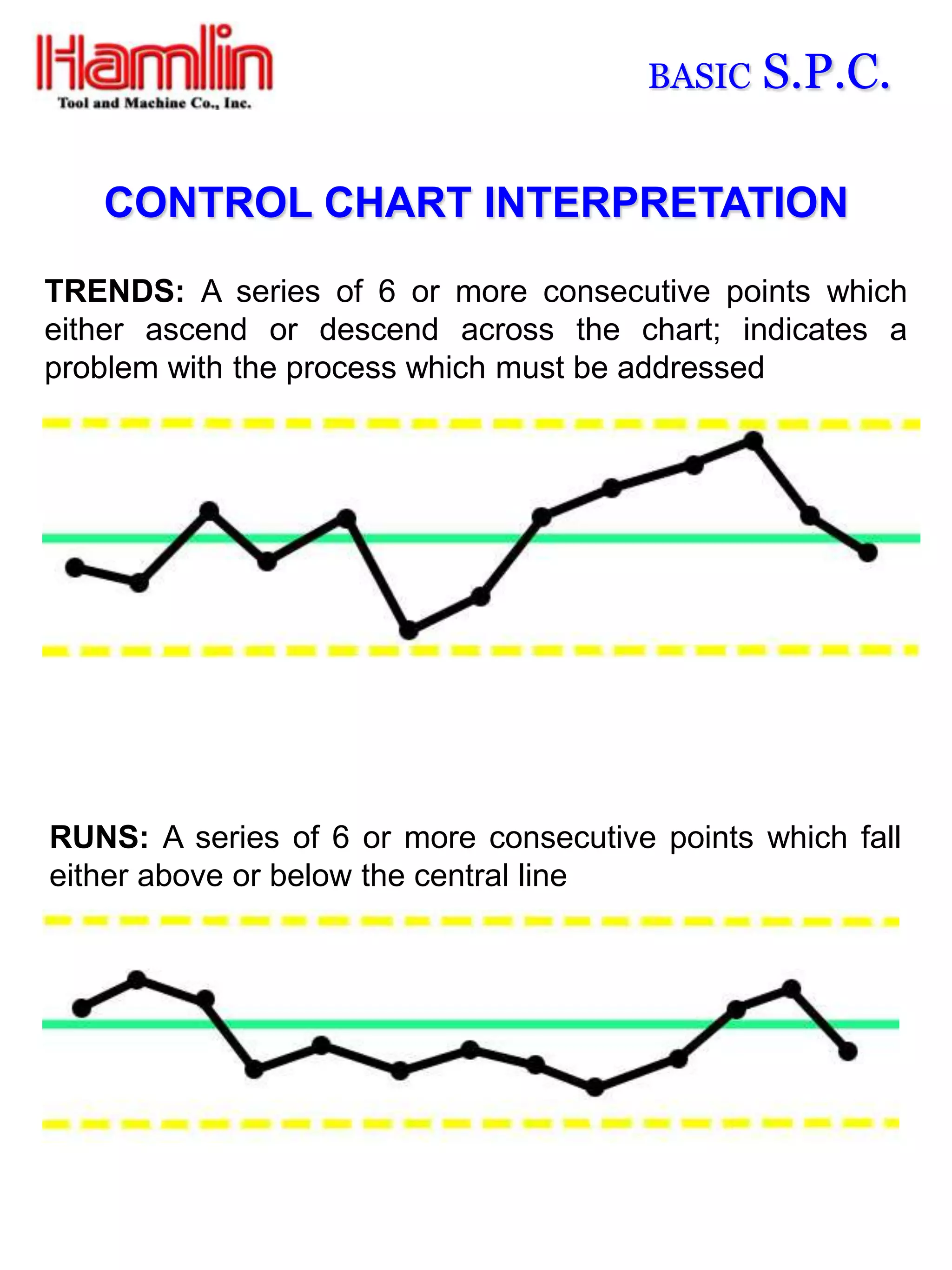

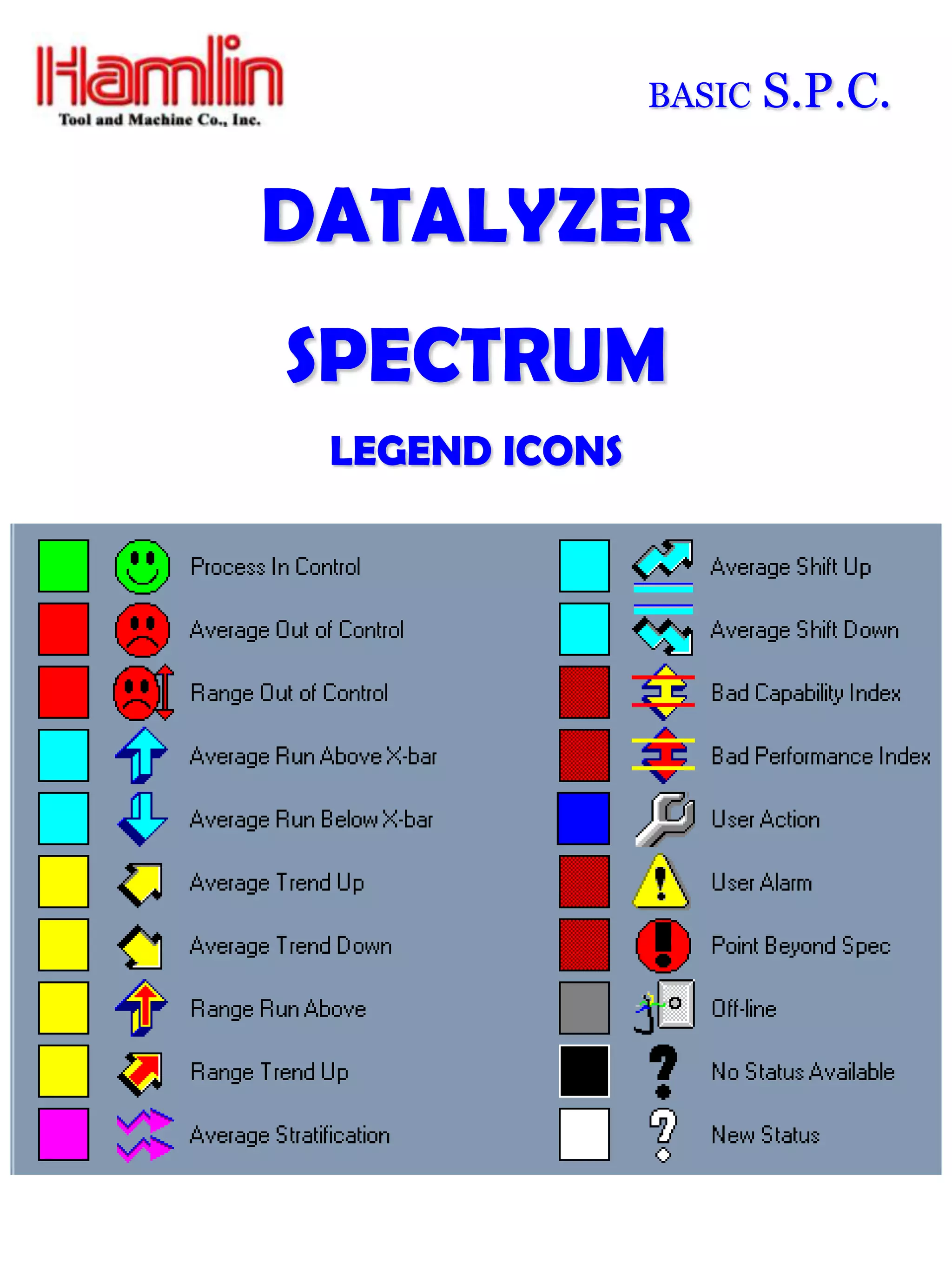

The document discusses statistical process control (SPC) and its use of statistical techniques like control charts to analyze processes and reduce variation. SPC helps maintain quality by increasing customer satisfaction, decreasing costs, and identifying sources of variation. The main tools of SPC are control charts, which plot sample measurements over time to monitor if a process is in or out of statistical control. Control charts can monitor variable characteristics using X-bar and R charts or attribute characteristics. Process capability and performance metrics like CpK and PpK are also discussed.