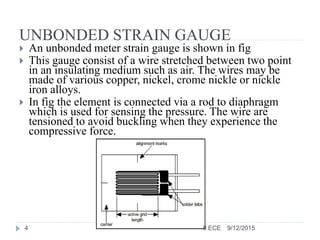

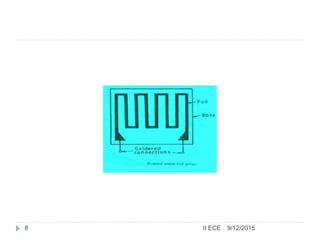

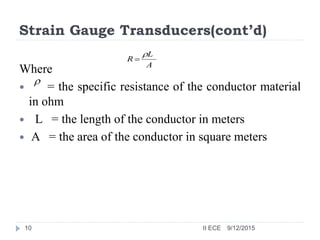

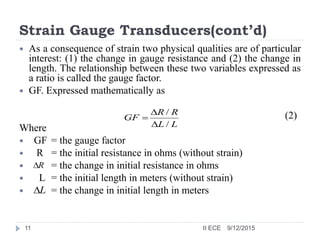

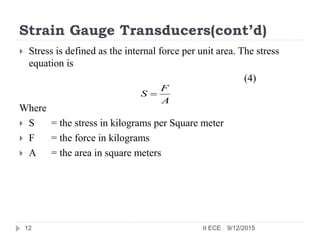

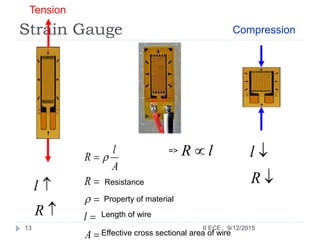

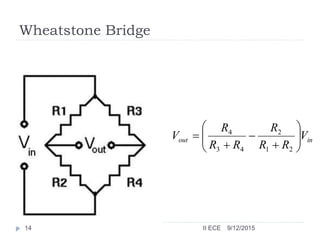

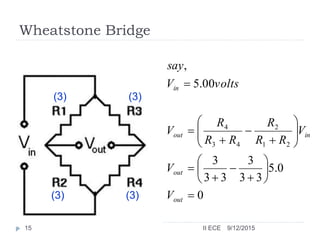

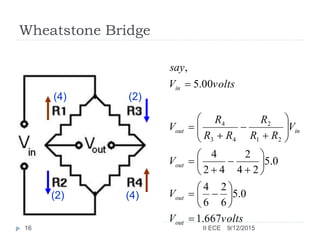

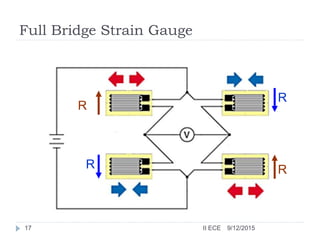

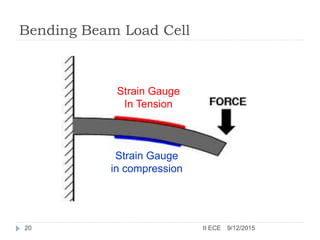

The strain gauge is a passive resistive transducer that converts mechanical strain into a resistance change. When an external force acts on the gauge, it changes the length and cross-sectional area of the gauge wire, altering its resistance. There are two main types: unbonded gauges, where the wire is stretched between points in air or another medium, and bonded gauges, where a fine wire grid is bonded to a carrier and then to the object under test. The resistance change is measured using a Wheatstone bridge circuit, which provides an output voltage proportional to the input strain and hence the applied force.