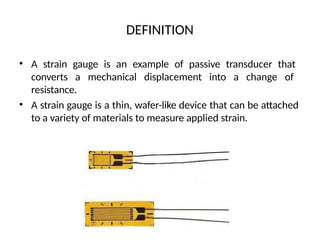

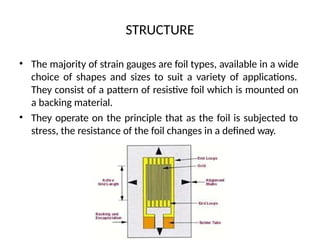

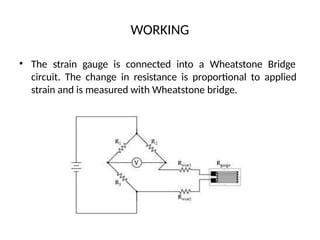

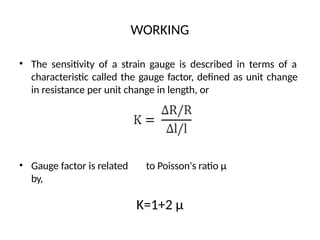

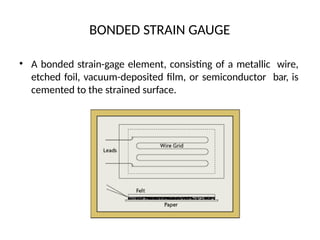

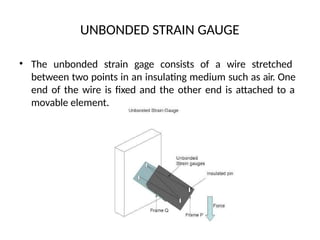

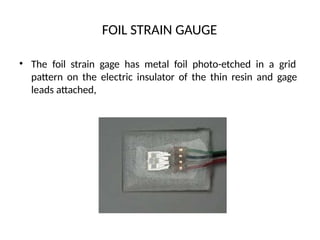

A strain gauge is a passive transducer used to measure applied strain by converting mechanical displacement into a change in resistance. The document outlines the history, working principles, types, advantages, disadvantages, and applications of strain gauges, highlighting their importance in various fields such as vibration and stress measurement. Key types include bonded and unbonded strain gauges, as well as different construction methods like foil and semiconductor gauges.