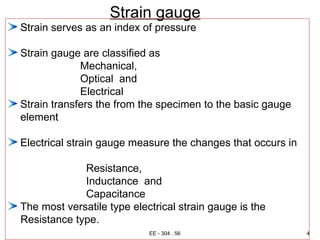

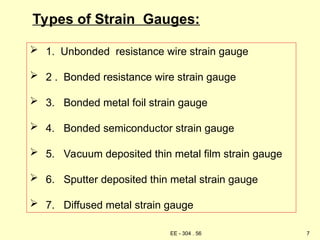

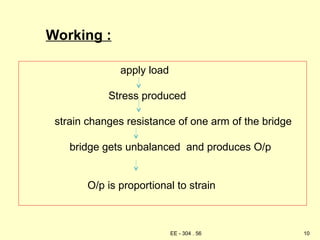

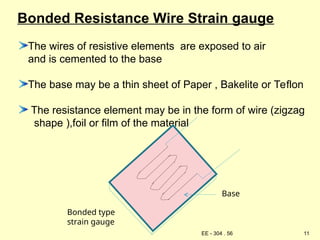

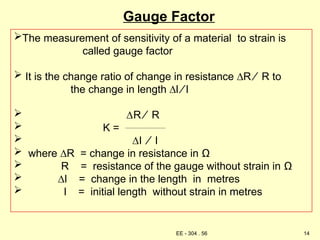

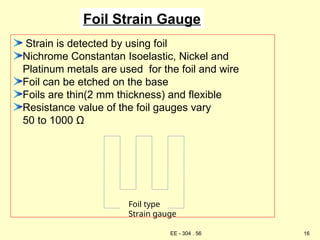

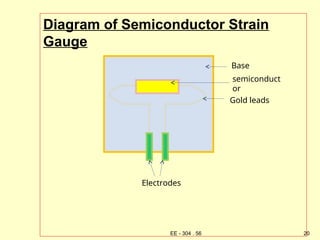

The document outlines the lesson plan for a lecture on transducers and sensors, focusing primarily on strain gauges. It details various types of strain gauges, their construction, working principles, and factors influencing the choice of transducers. The document also includes objectives for student learning outcomes and quiz questions for assessment.