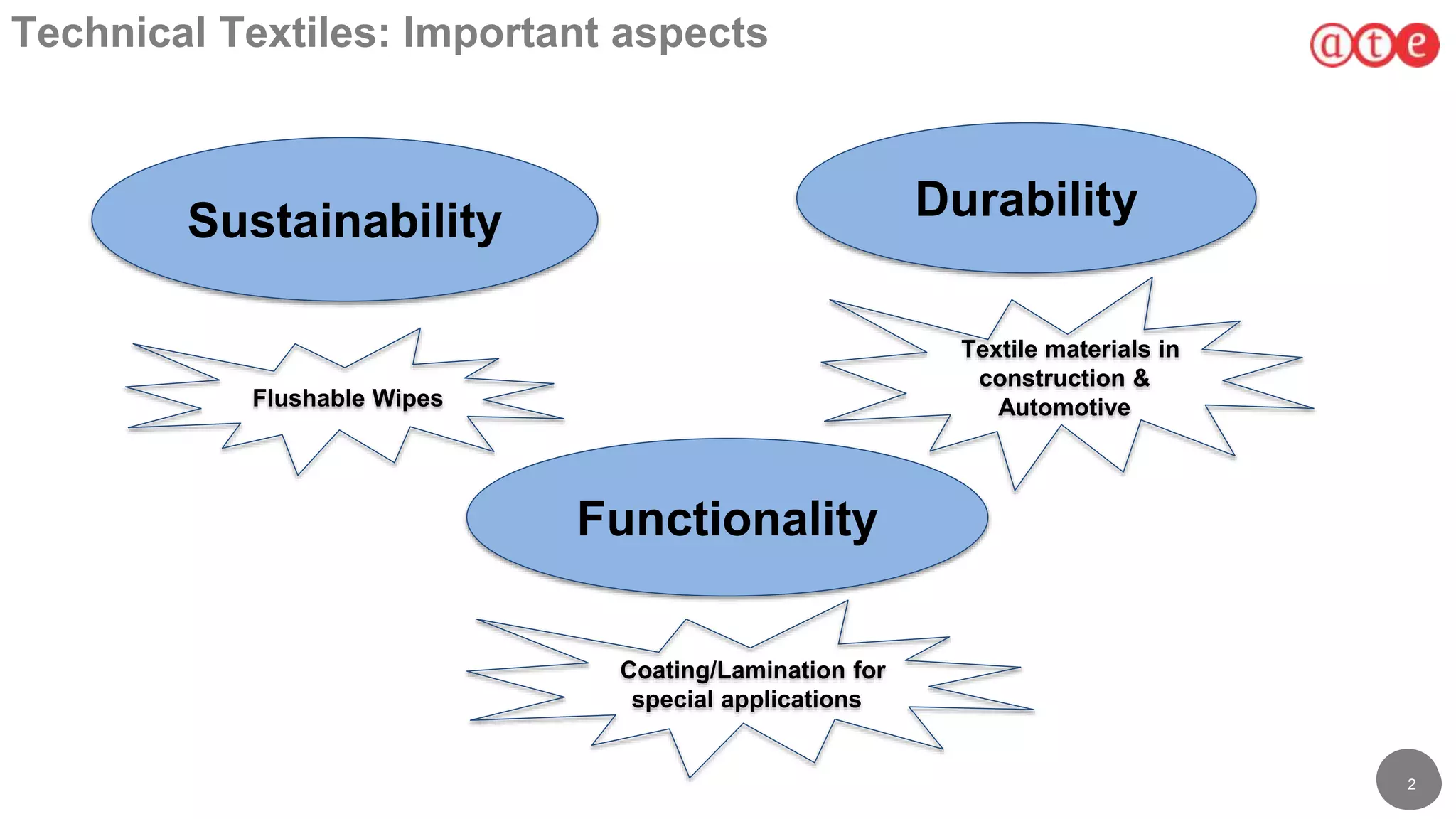

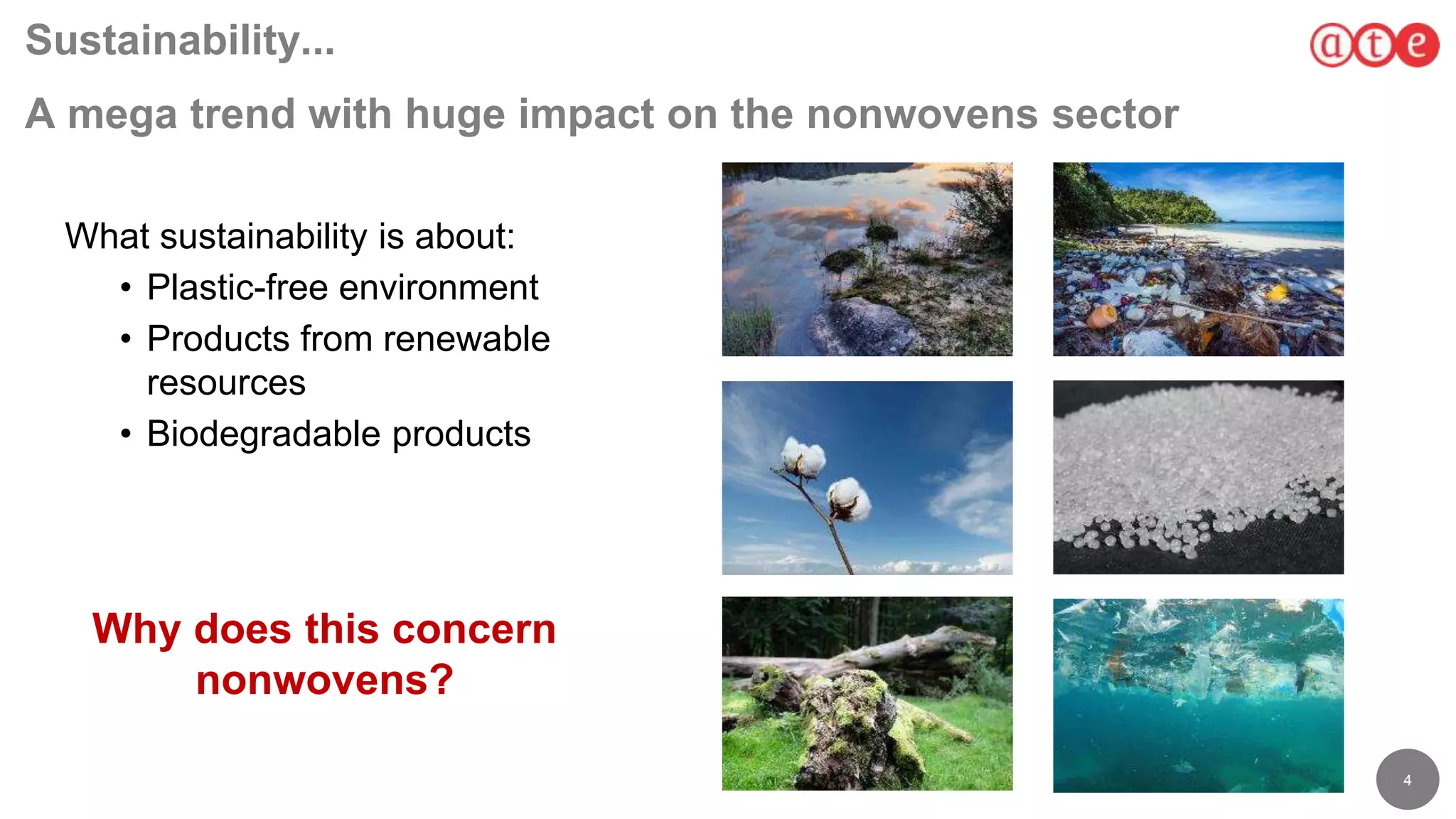

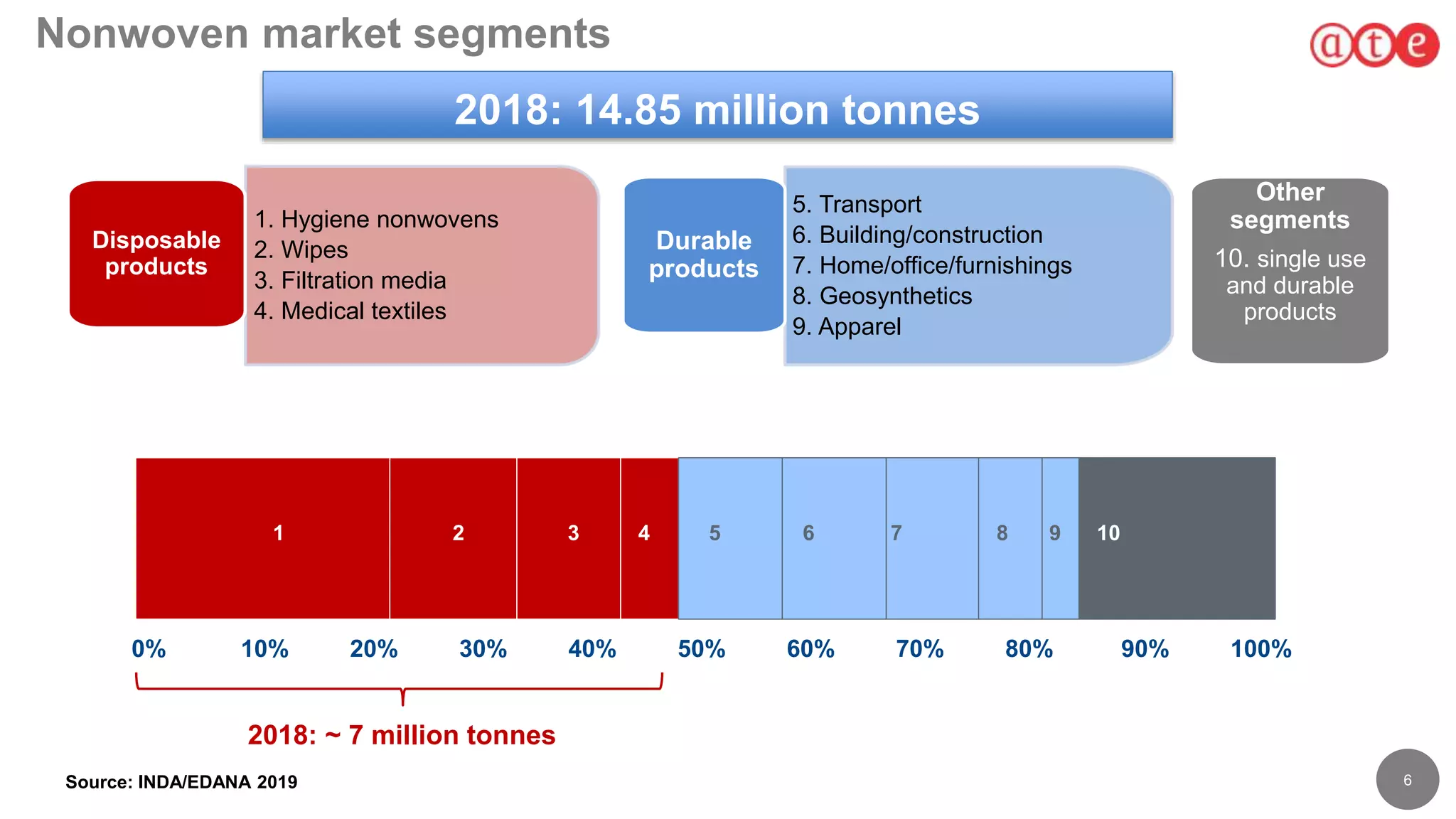

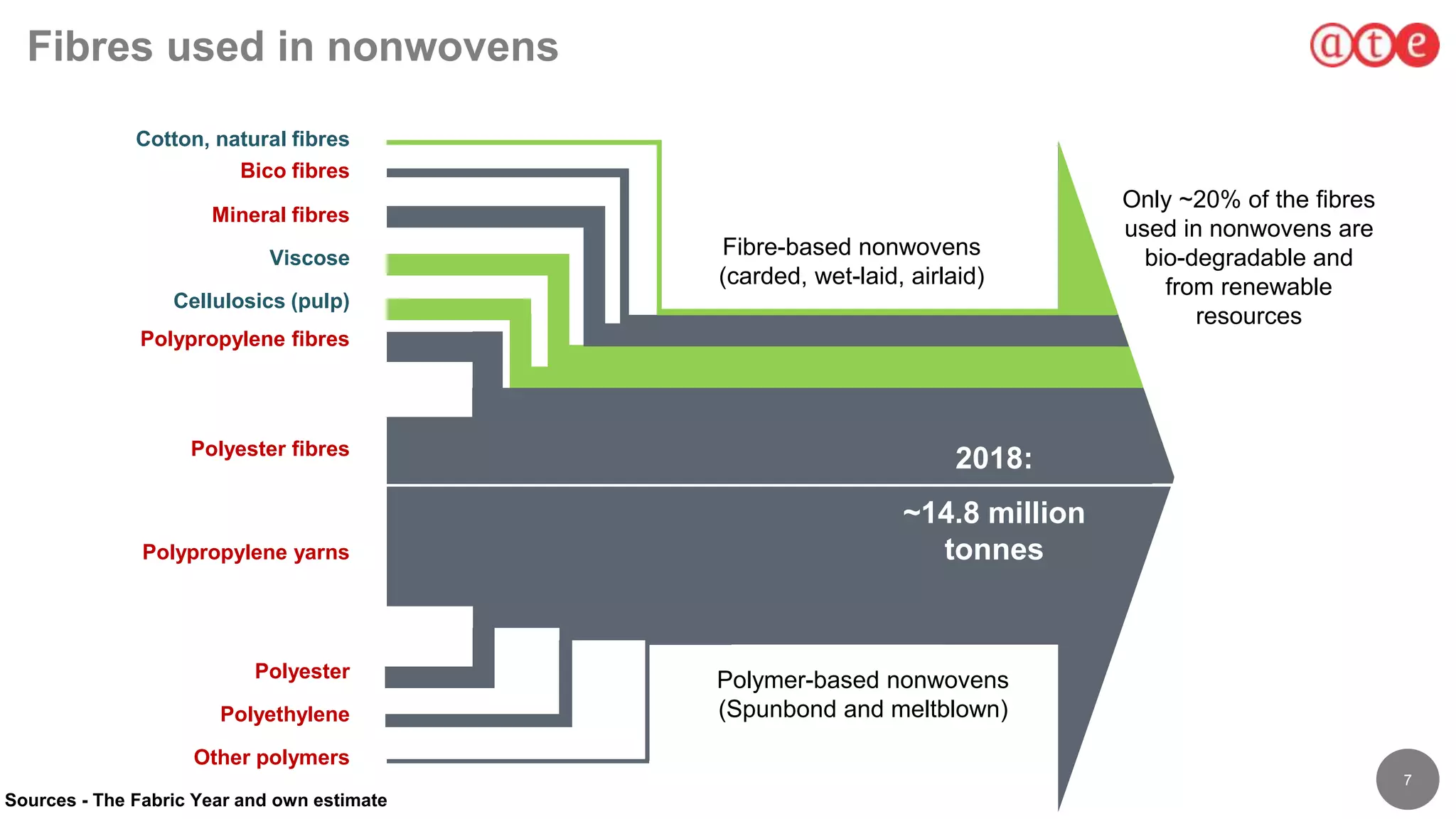

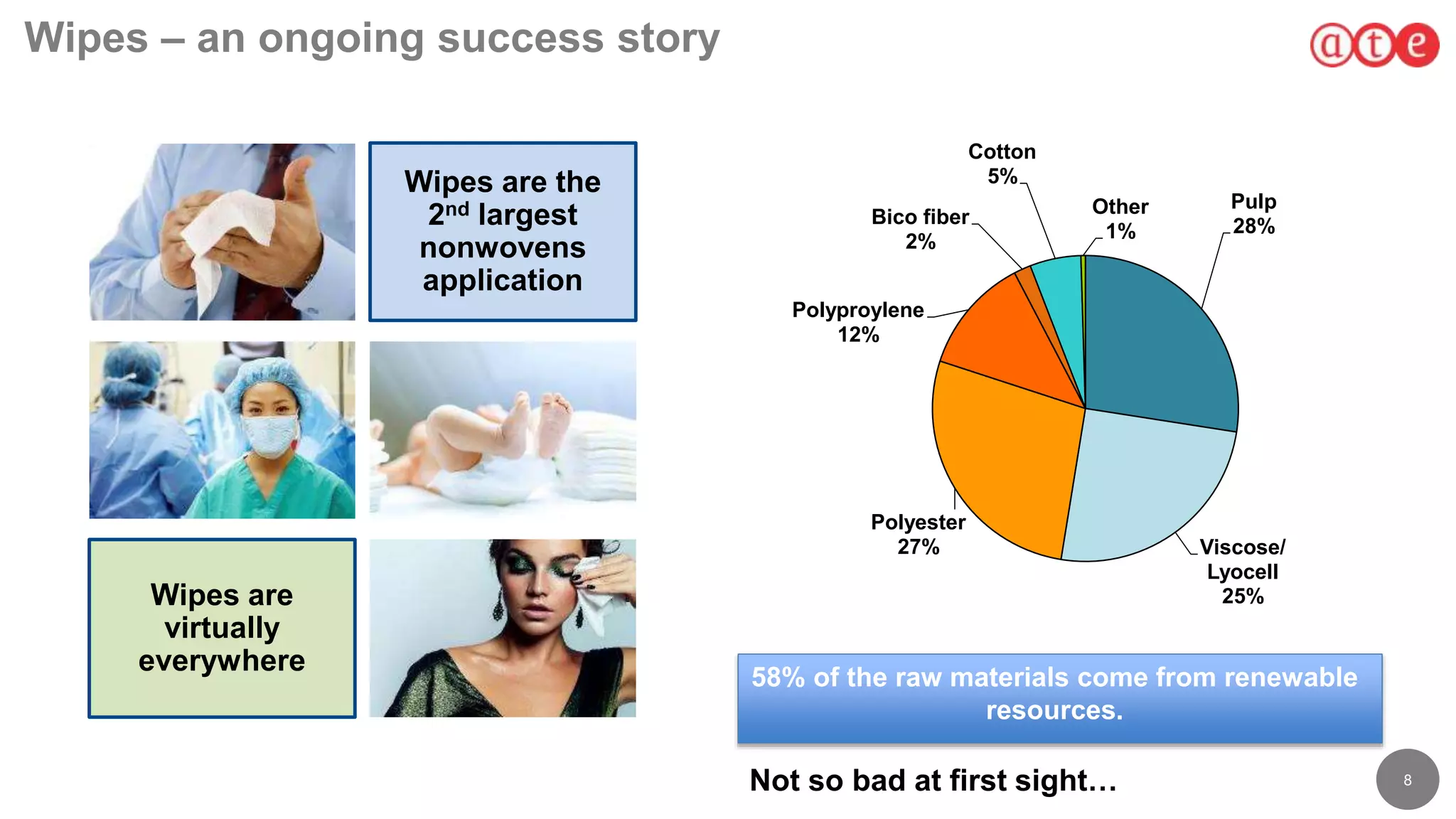

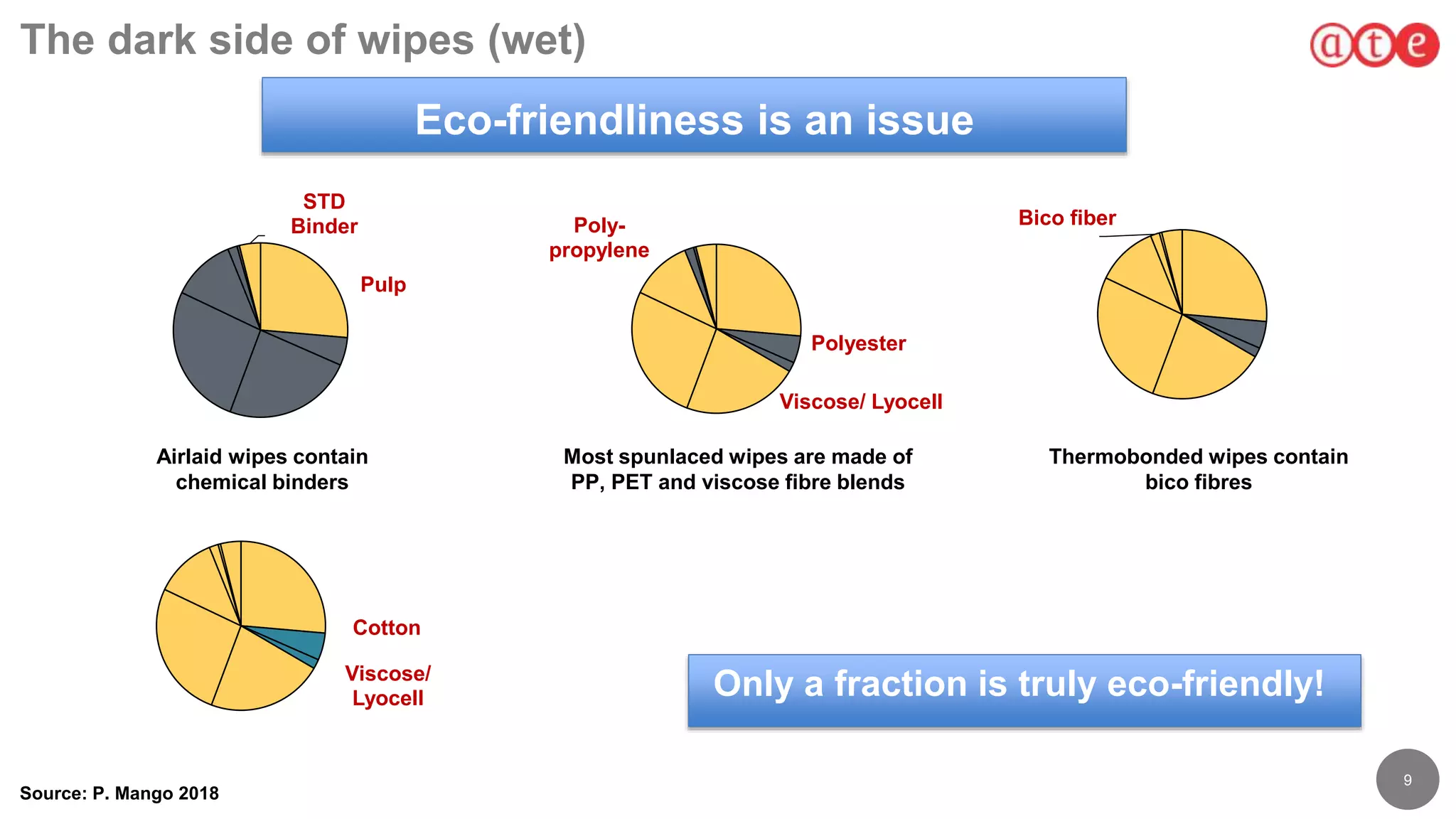

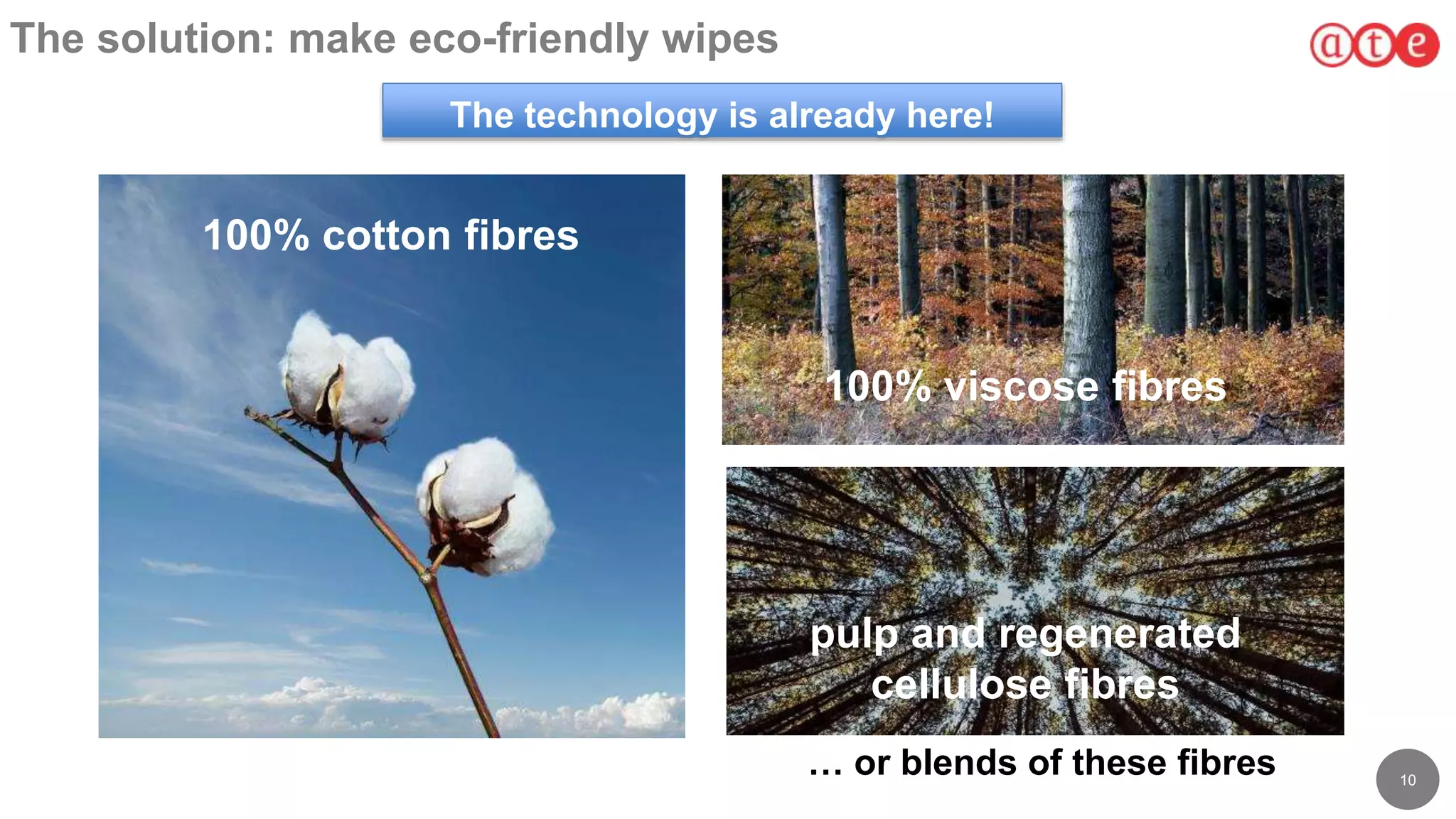

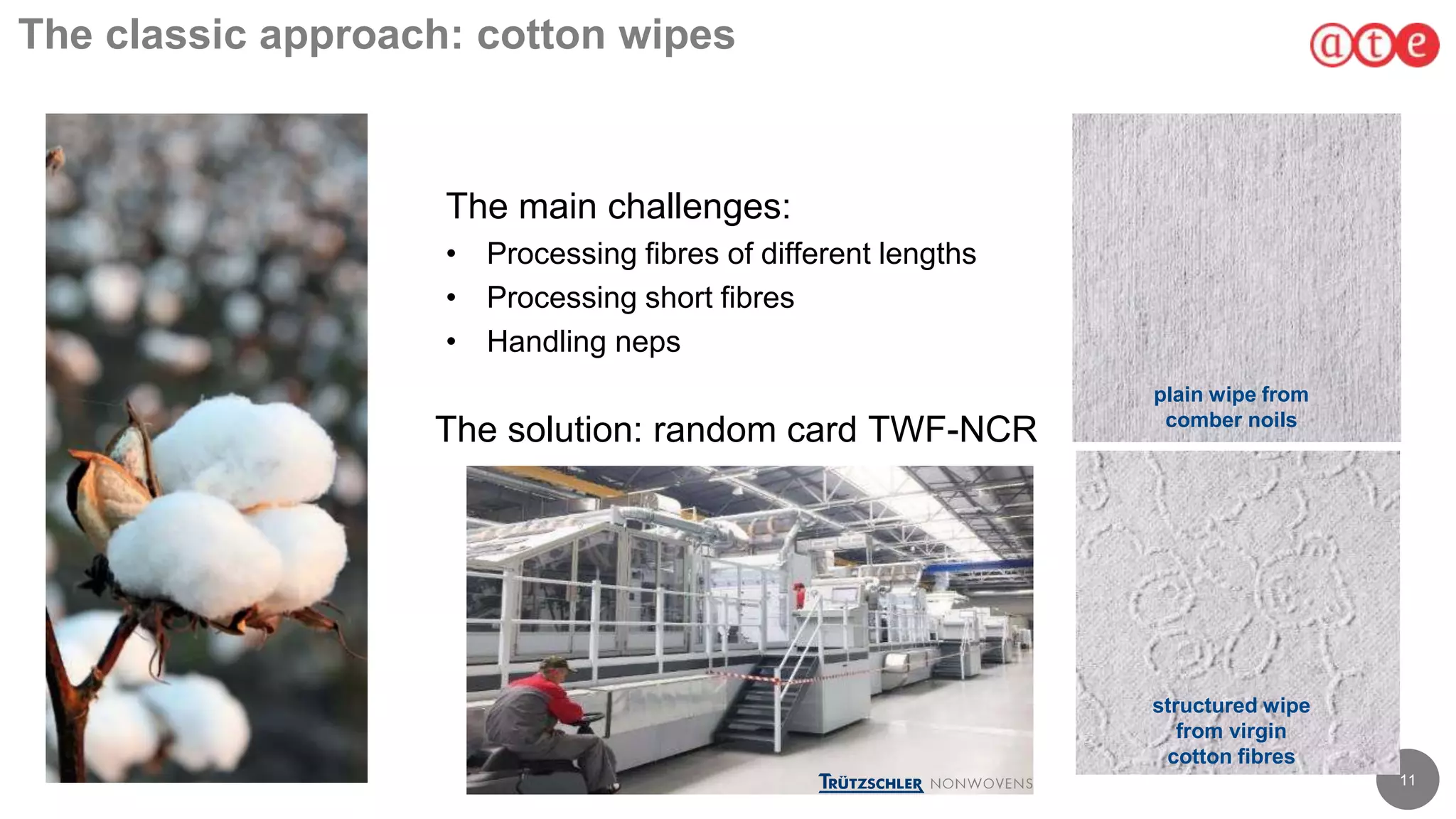

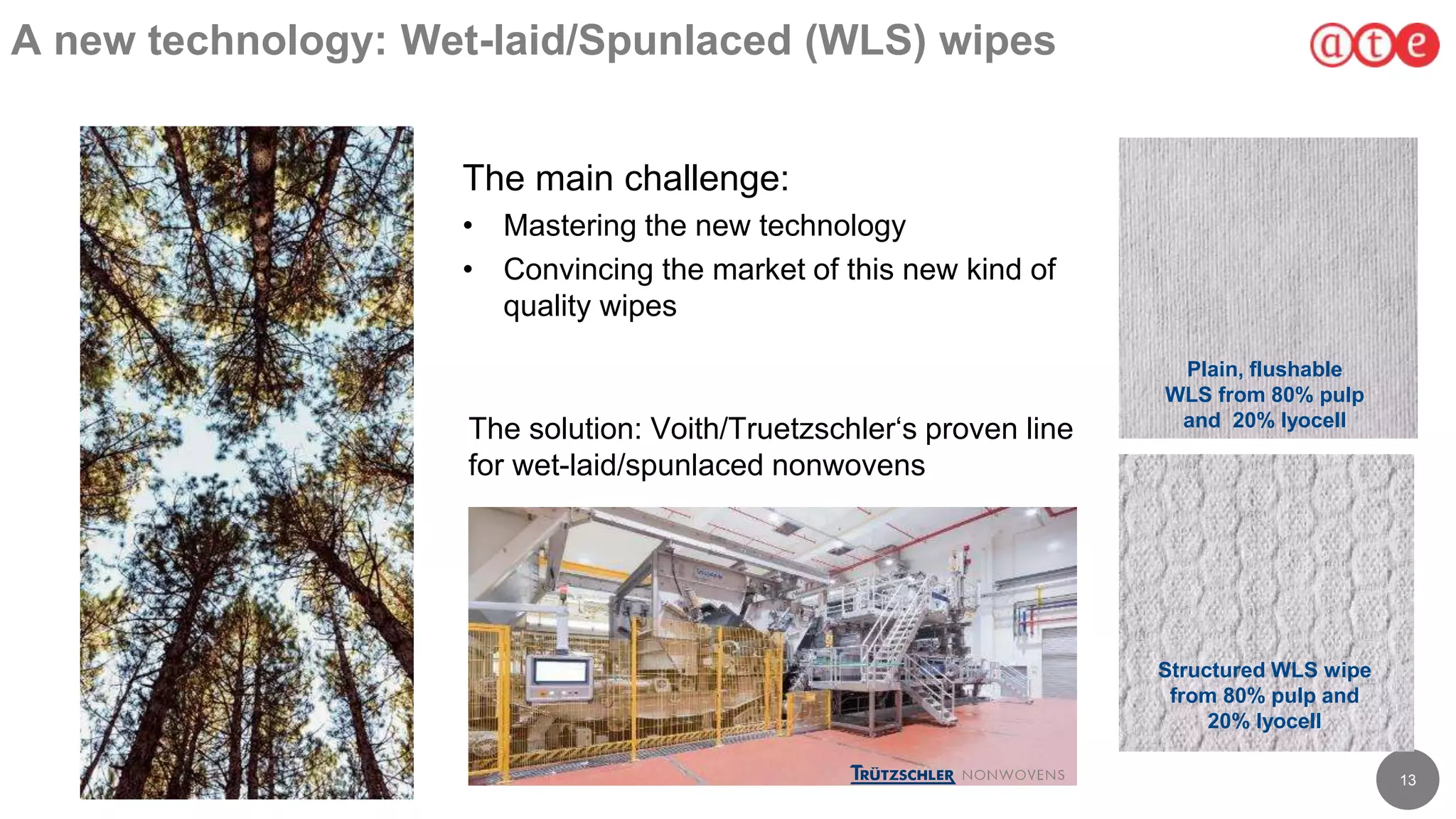

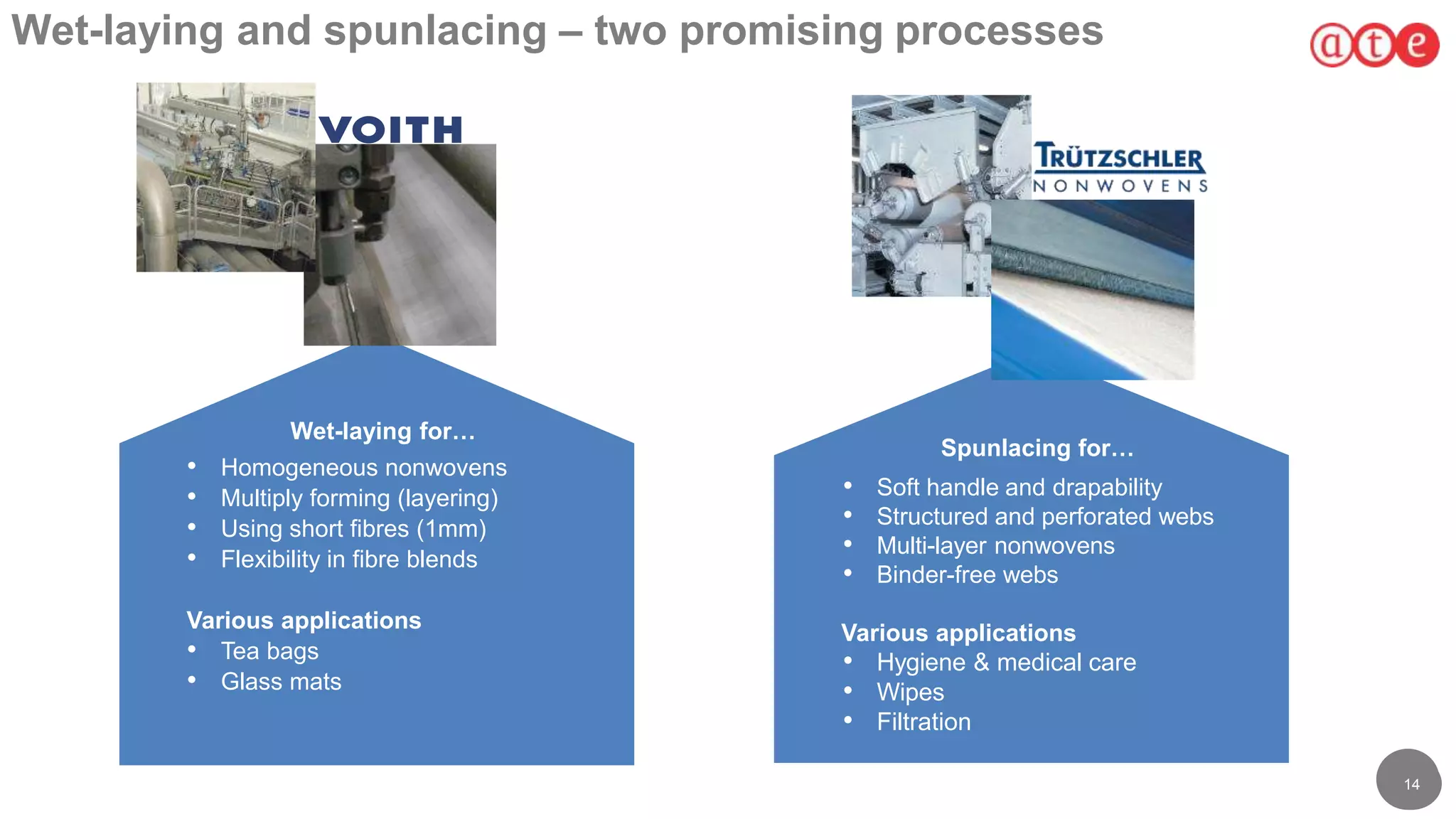

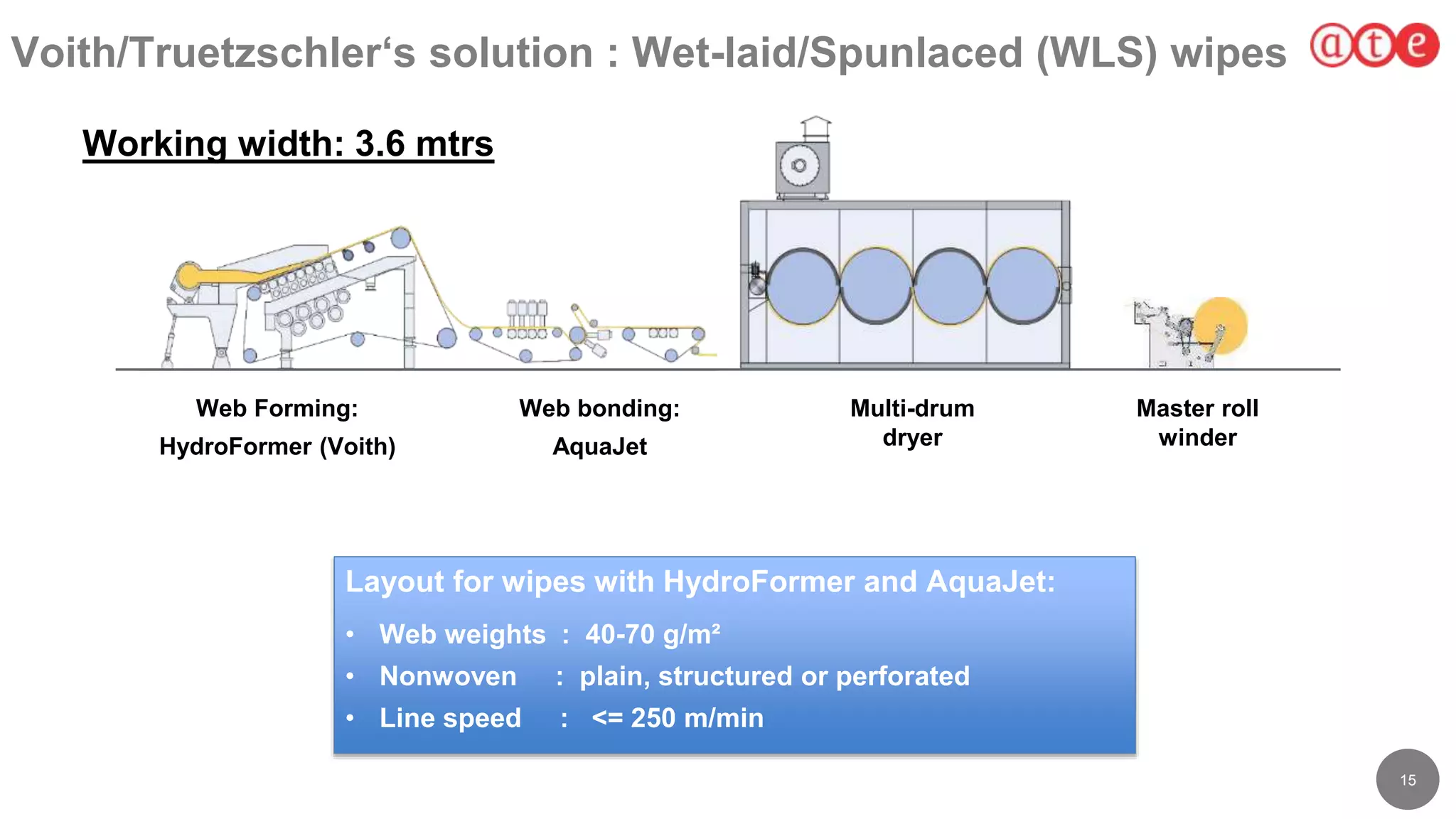

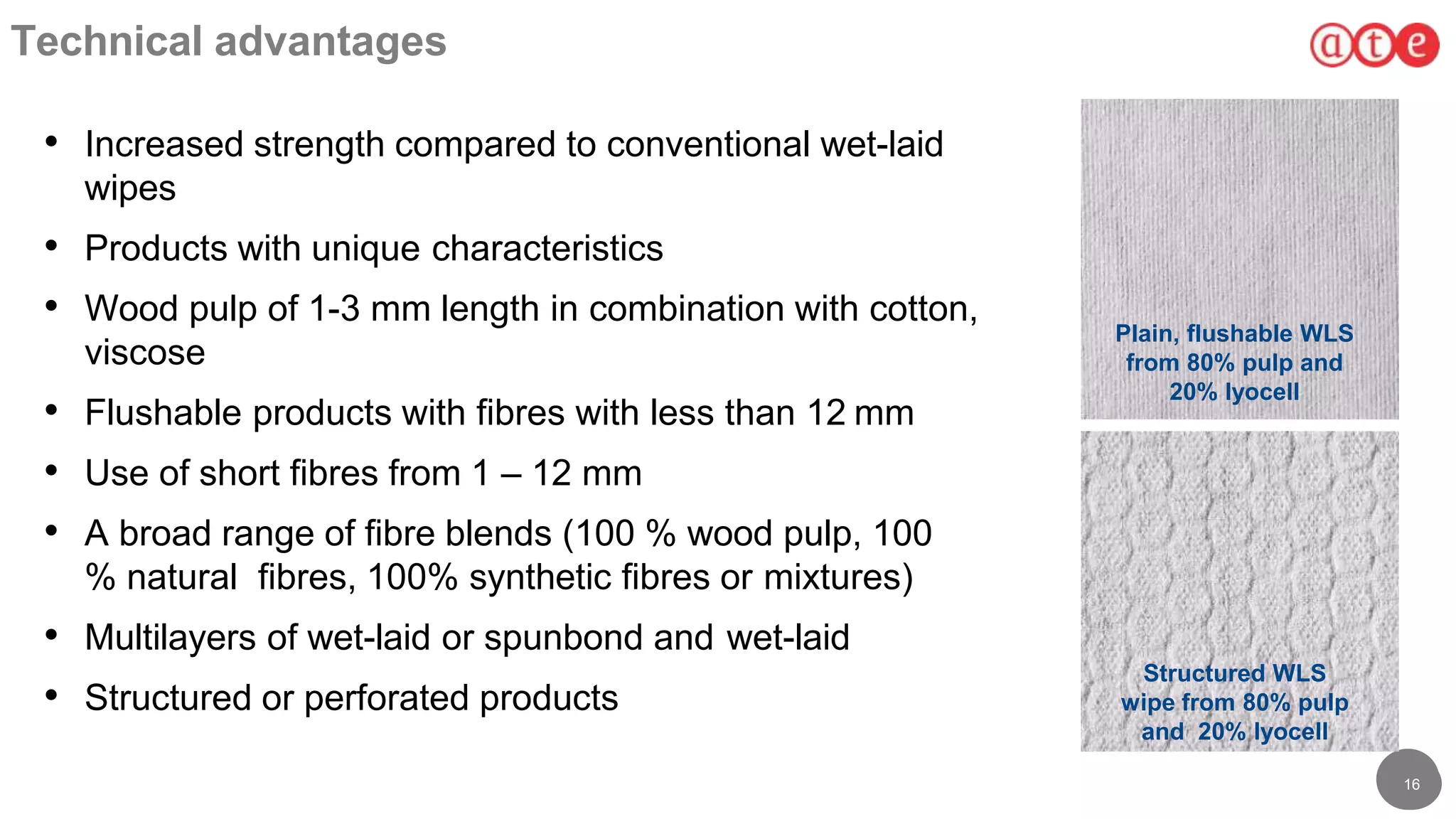

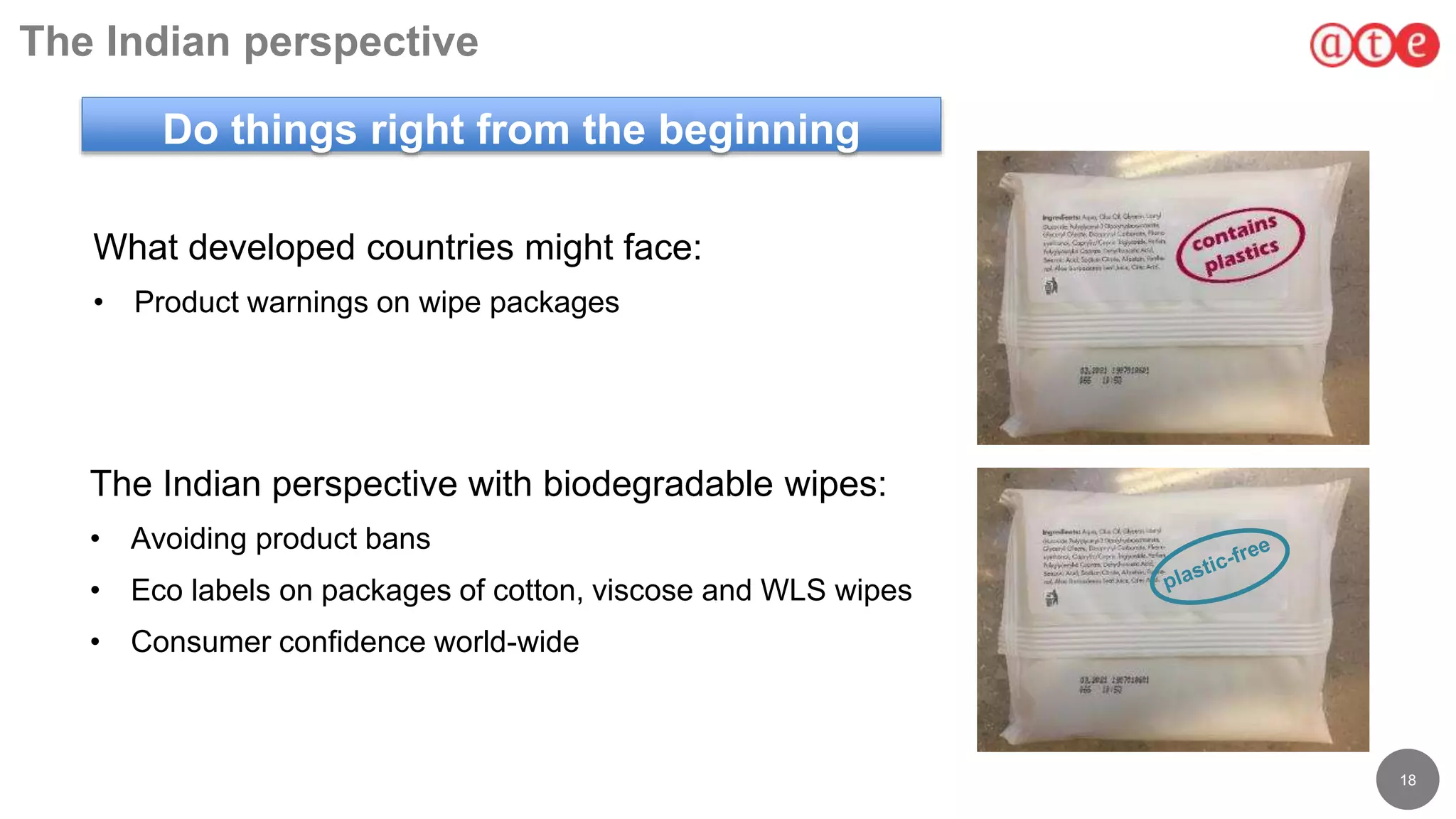

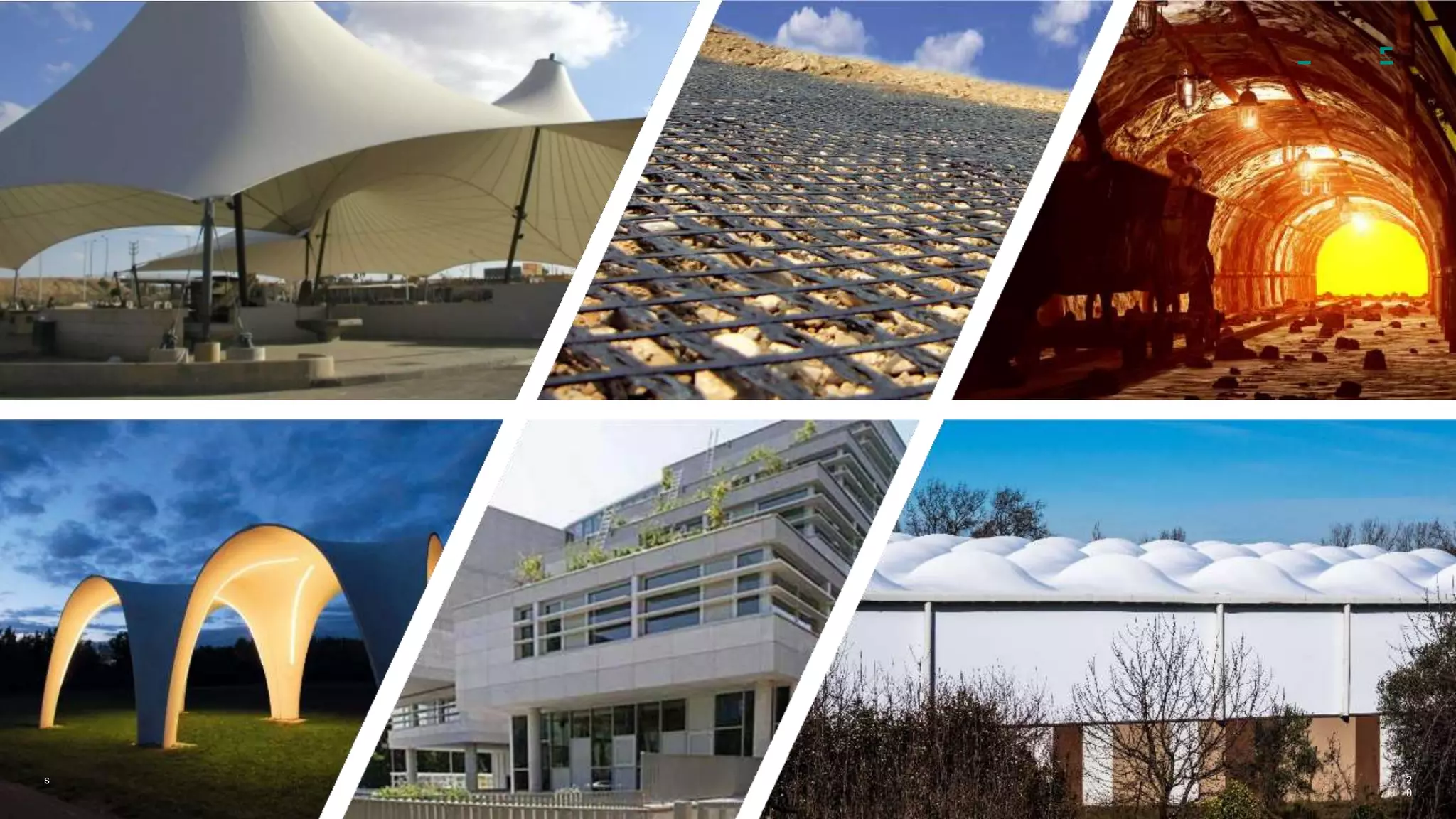

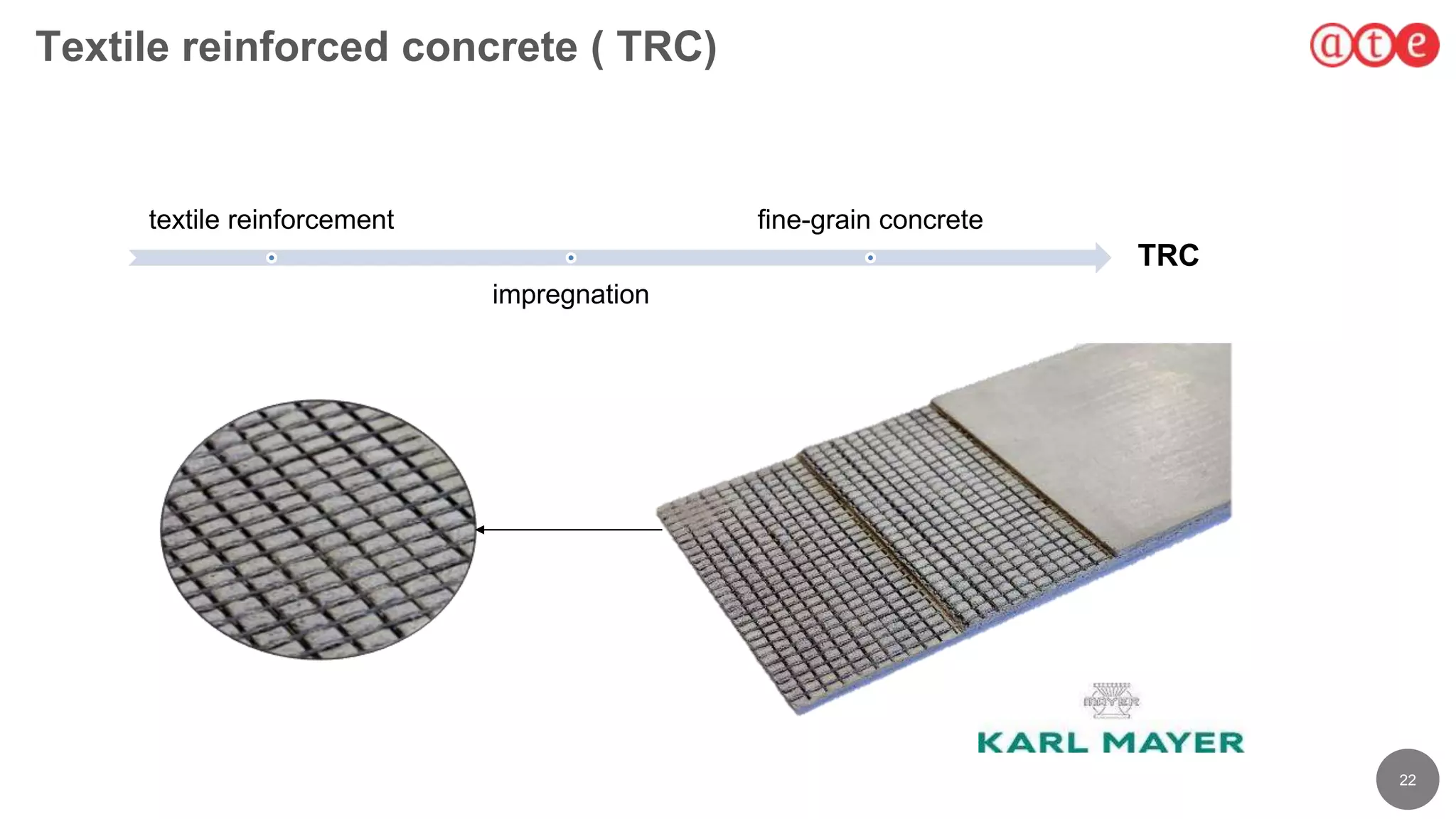

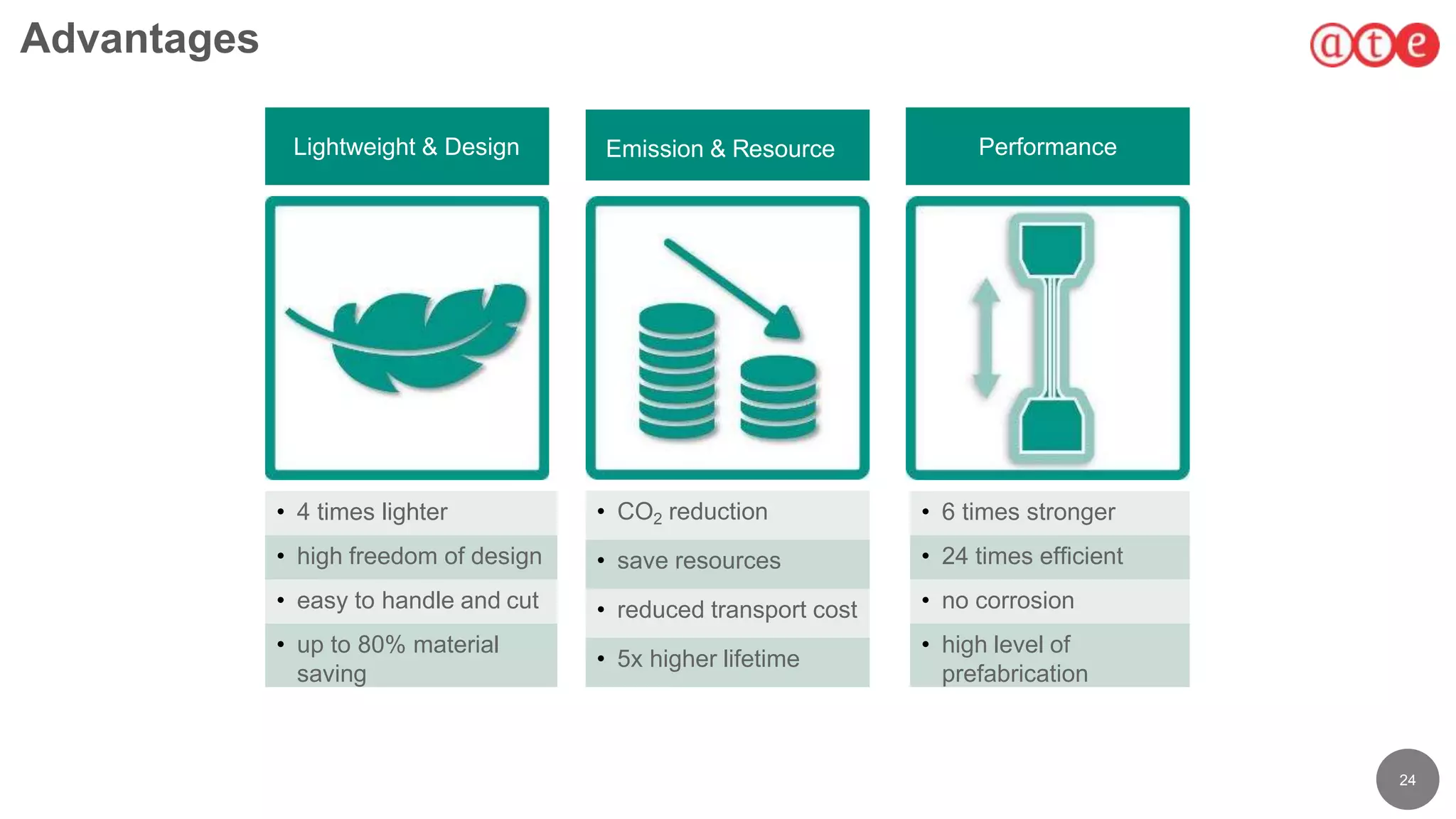

The document discusses technological advancements in the field of technical textiles, focusing on sustainability and eco-friendly practices within the nonwovens sector. It highlights the importance of biodegradable materials, presents new technologies for wipes production, and explores innovative reinforcement methods for construction textiles. Additionally, it emphasizes the global challenge of plastic pollution and India's positioning on sustainability initiatives in textile manufacturing.