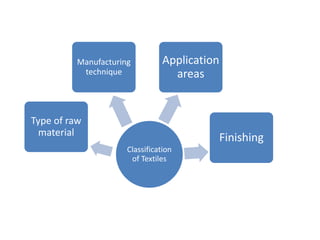

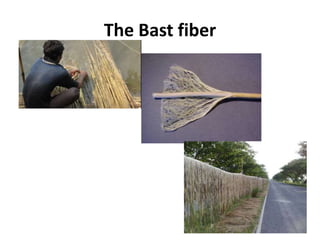

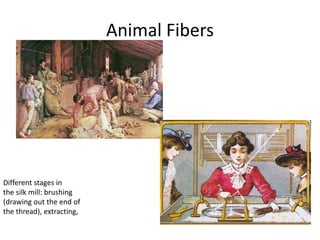

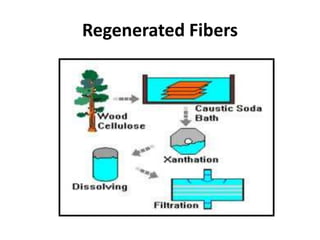

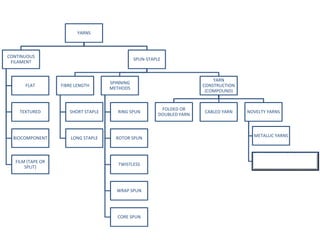

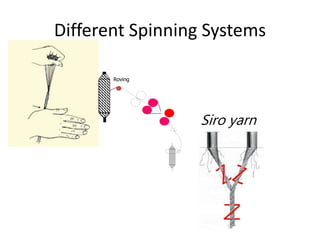

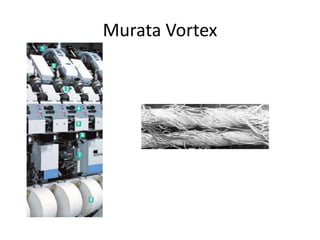

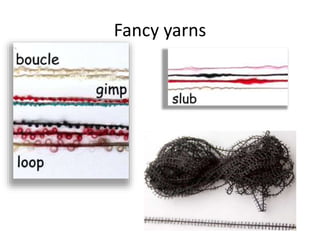

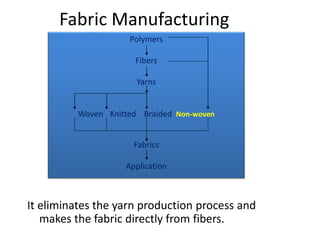

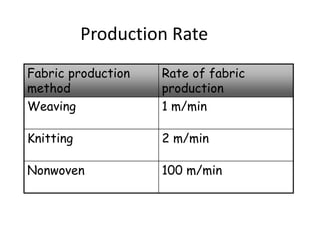

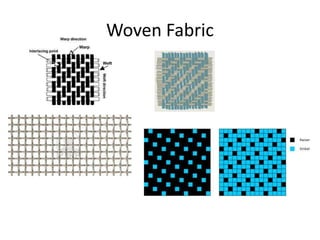

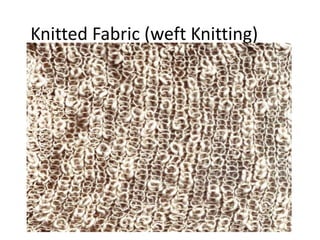

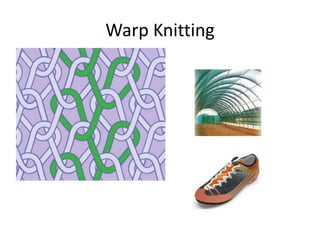

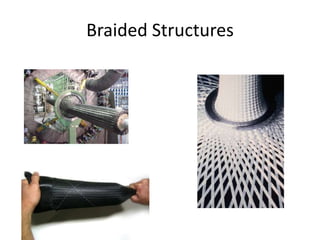

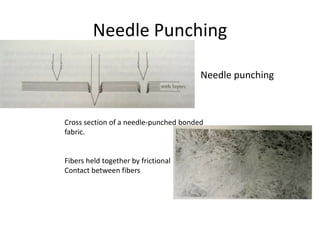

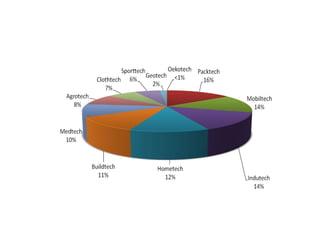

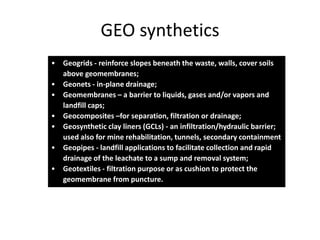

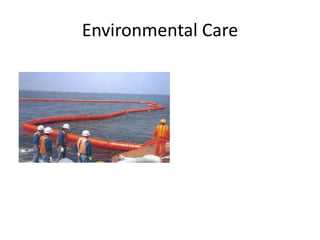

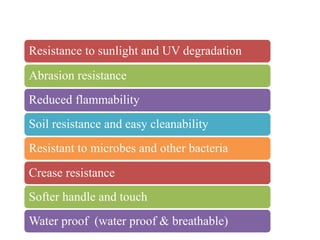

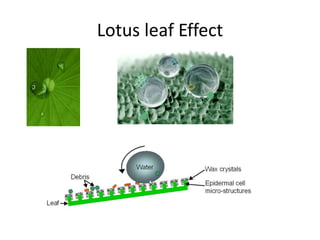

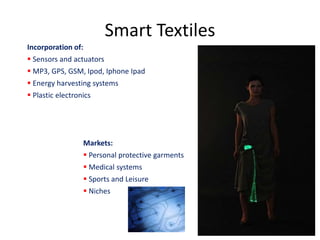

This document provides an overview of textile classification and manufacturing processes. It discusses the origins of fibers as either natural (plant, animal, mineral) or man-made (regenerated, synthetic, high performance). Common yarn production methods like spinning and types of fabrics like woven, knitted and non-woven are described. The document also outlines various textile finishing techniques and applications in areas like technical textiles, construction, marine, environment and smart textiles.