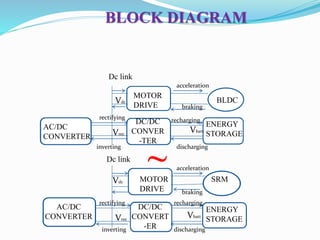

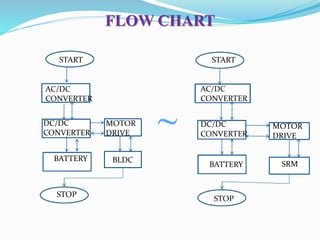

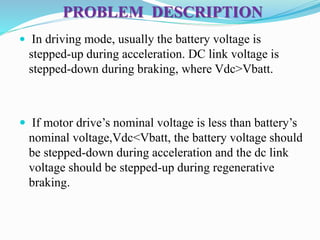

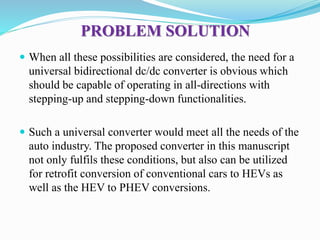

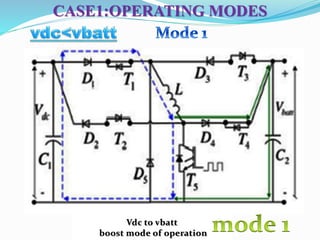

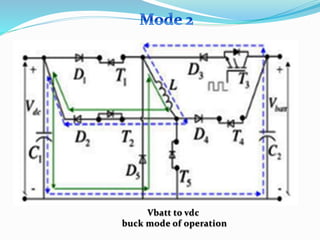

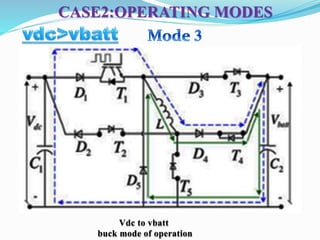

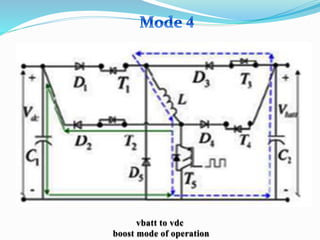

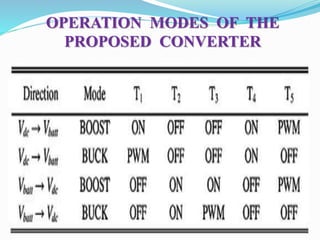

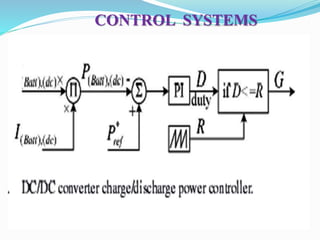

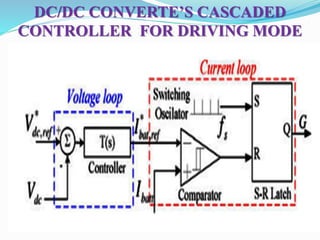

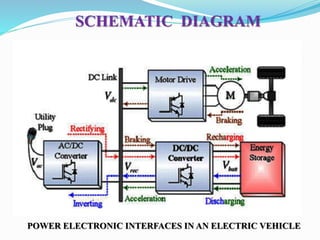

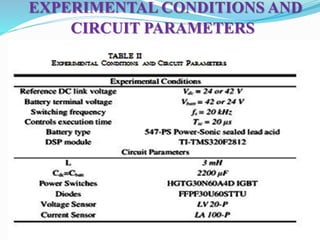

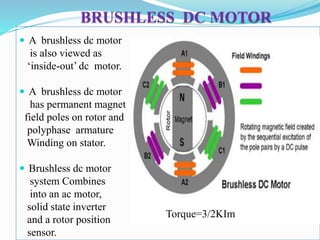

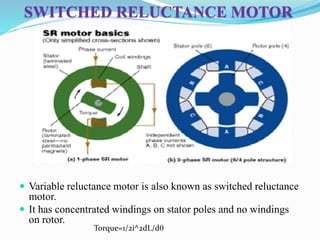

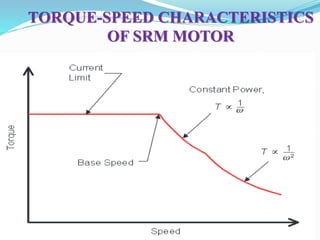

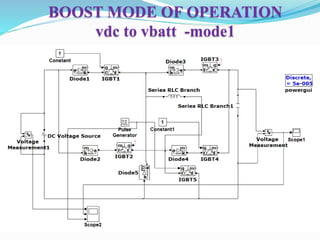

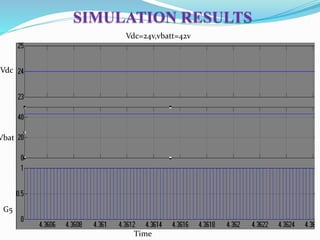

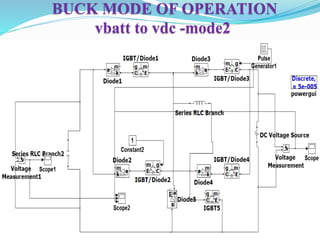

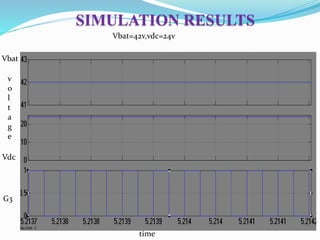

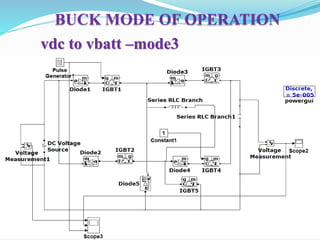

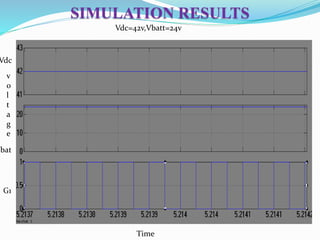

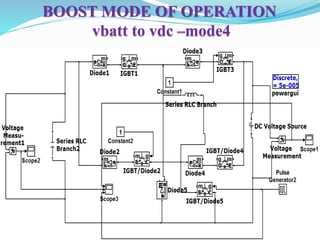

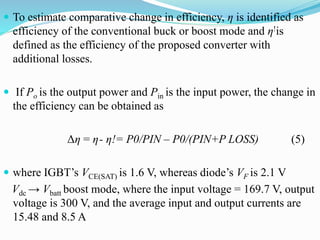

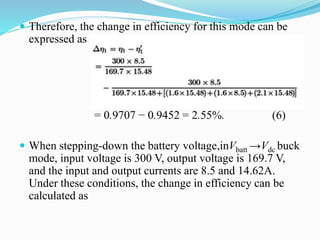

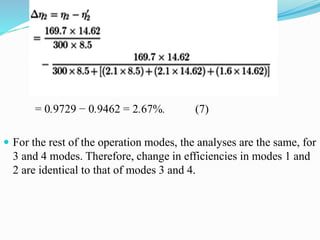

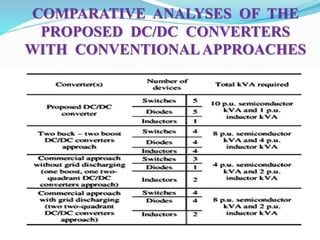

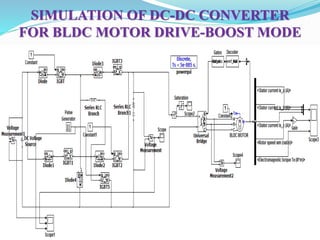

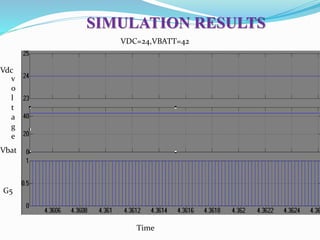

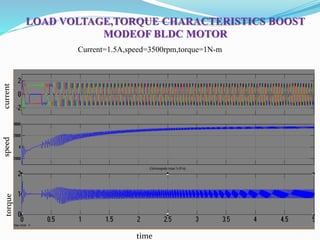

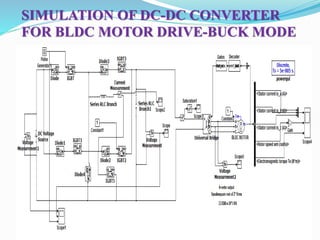

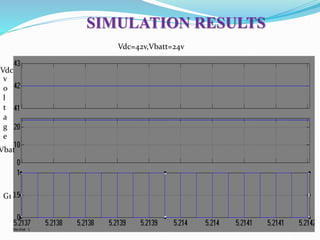

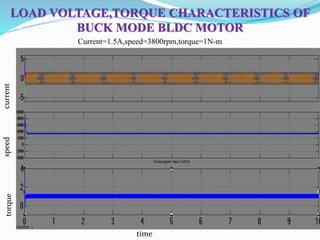

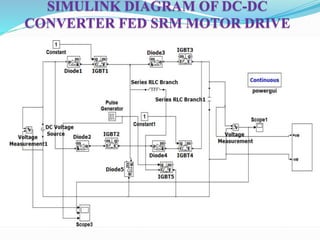

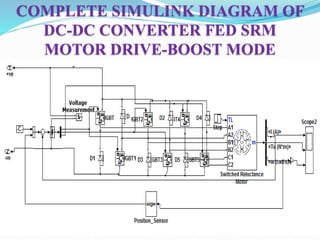

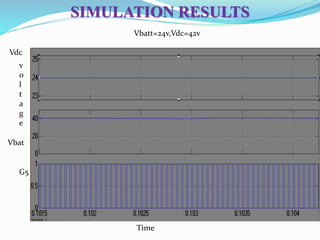

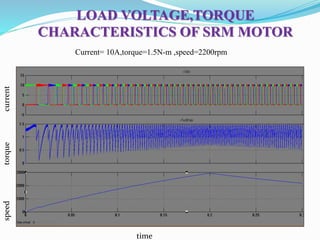

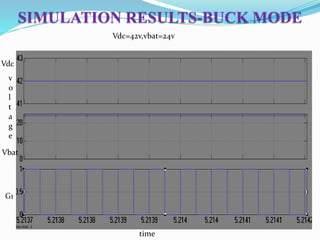

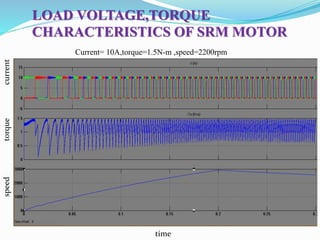

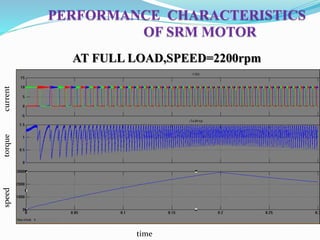

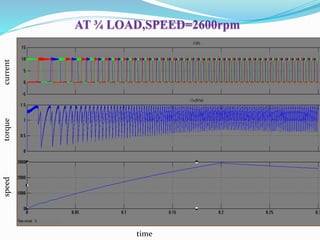

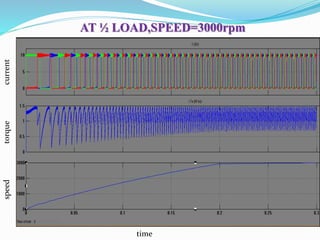

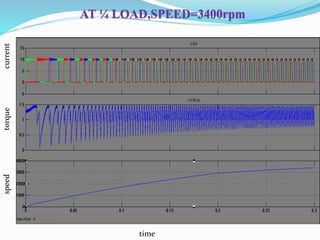

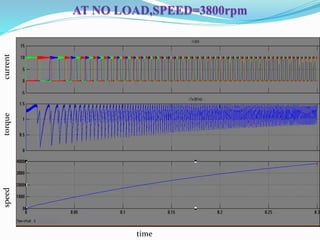

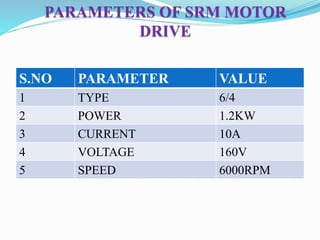

This document describes a proposed universal bidirectional DC-DC power converter that can interface an energy storage device (such as a battery) with a motor drive for electric vehicles. The converter can step up or step down voltages in both directions with bidirectional power flow. It is capable of operating in all modes needed for applications like charging, accelerating, braking and discharging. Simulation results show it efficiently operates switched reluctance and BLDC motors in different voltage scenarios. The proposed converter reduces costs and components compared to using separate buck and boost converters.