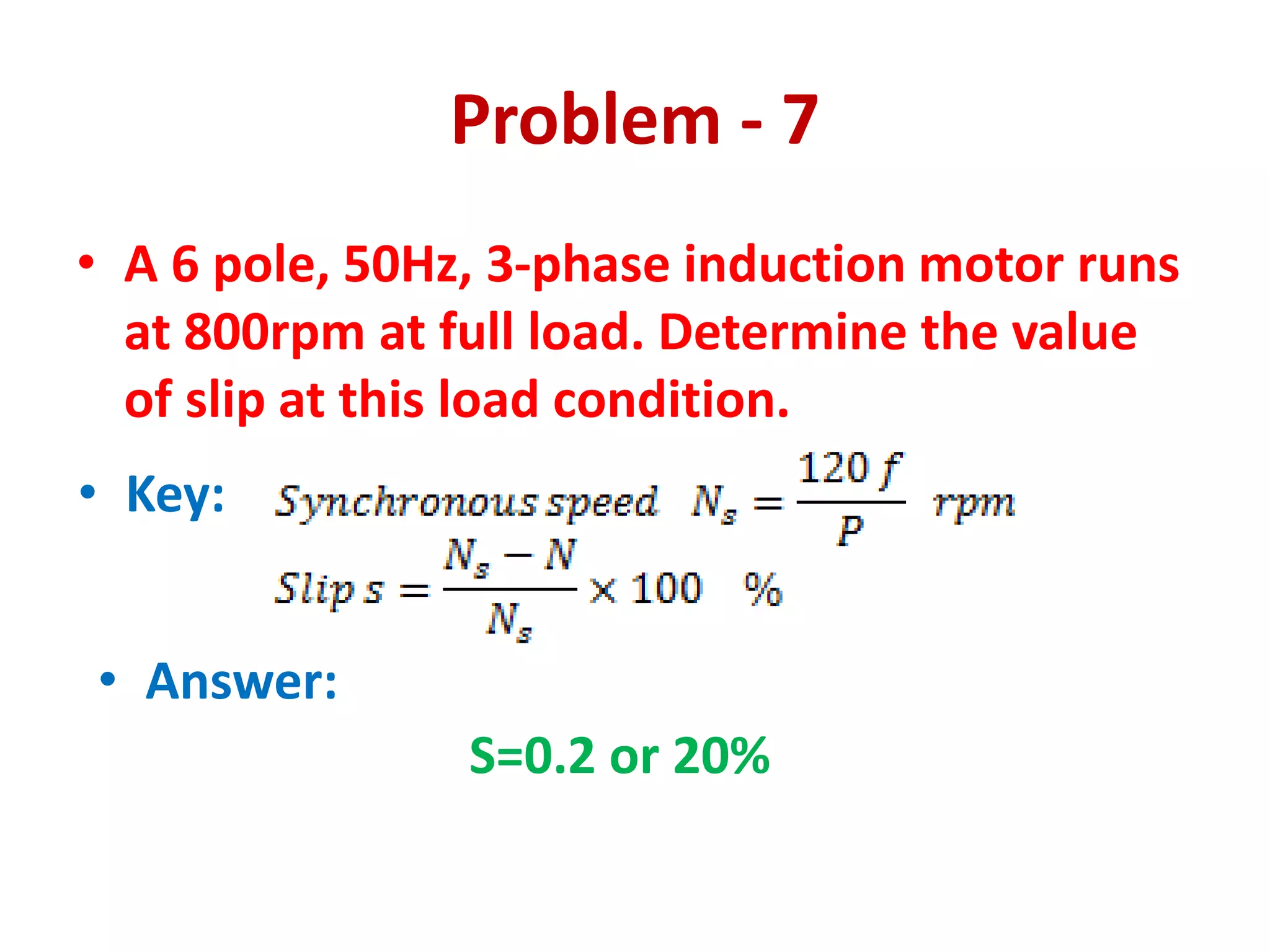

The document provides an in-depth overview of three-phase induction motors, detailing their construction, types of rotors, principle of operation, slip-torque equations, and performance characteristics. It covers the advantages and disadvantages of induction motors, different types of rotor constructions (squirrel cage and slip ring), and important tests such as load, no-load, and blocked rotor tests. Key concepts like slip, torque characteristics, efficiency, and phenomena such as cogging and crawling are also discussed.