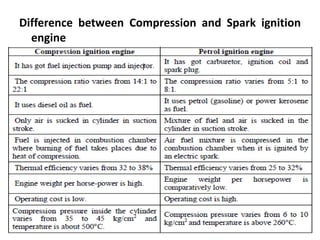

There are two main types of internal combustion engines: spark ignition engines (gasoline/petrol engines) and compression ignition engines (diesel engines). Spark ignition engines use a carburetor to mix air and fuel, which is then ignited by a spark plug. Compression ignition engines only draw in air, and fuel is injected at the end of the compression stroke and ignites due to the high temperature from compression. Both types of engines require a cooling system to remove excess heat from combustion and maintain optimal engine temperatures for efficient operation and protection of components like the cylinder and piston.