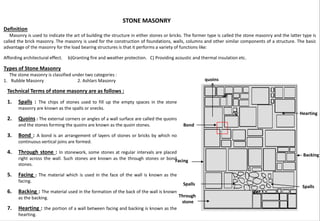

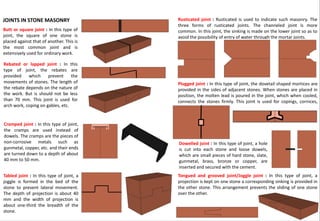

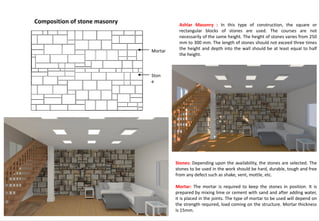

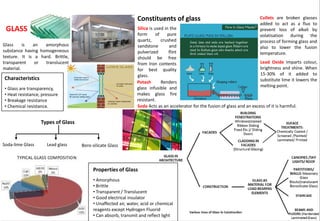

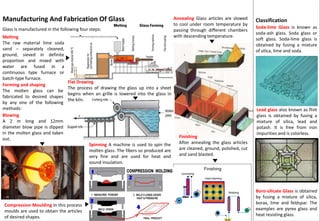

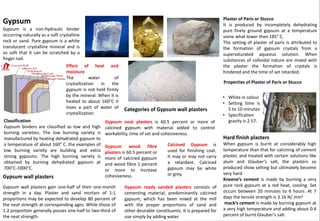

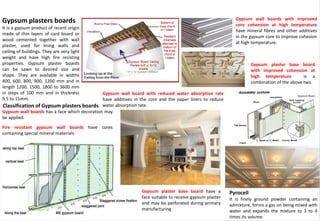

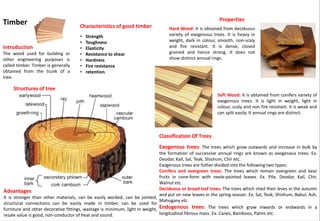

This document provides information about various construction materials used in building interiors, including stone masonry, brick masonry, glass, gypsum, and timber. For each material, it describes definitions, types, properties, manufacturing processes, and commercial forms. The document is a student project report submitted to Dezyne E'cole College by Sonal Gupta towards her 1st year residential design diploma. It includes an acknowledgment, synopsis, and sections on each material.