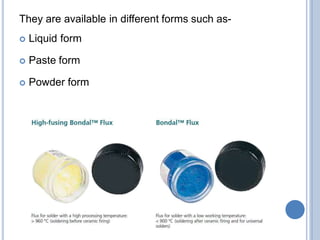

This document discusses soldering and welding techniques used in prosthodontics. It defines soldering as joining metals below 450°C using a filler metal, while welding joins metals without a filler by heating. Soldering is used to join components of fixed and removable partial dentures. It requires cleaning the joining surfaces, assembling parts, fluxing, controlling heat, and adding filler metal. Different types of solders, fluxes, and welding techniques are described. The conclusion states that soldering requires technique sensitivity and may improve accuracy, while new technologies may replace it.