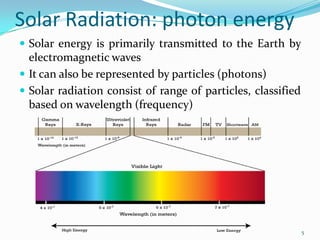

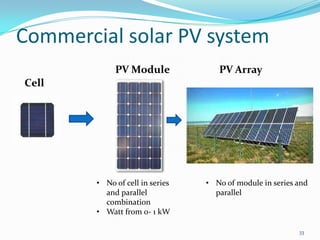

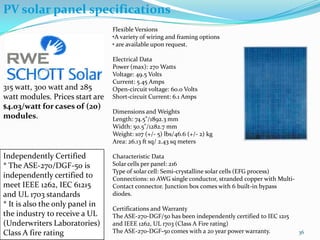

The document provides information about solar cells and photovoltaic technology. It discusses how solar cells work using the photovoltaic effect to convert sunlight into electricity. It describes the basic components of solar cells including semiconductor materials like silicon, the p-n junction, and how sunlight generates electron-hole pairs that create voltage. It also outlines the characteristics and efficiency of solar cells as well as common types of solar cells used in photovoltaic modules and systems.