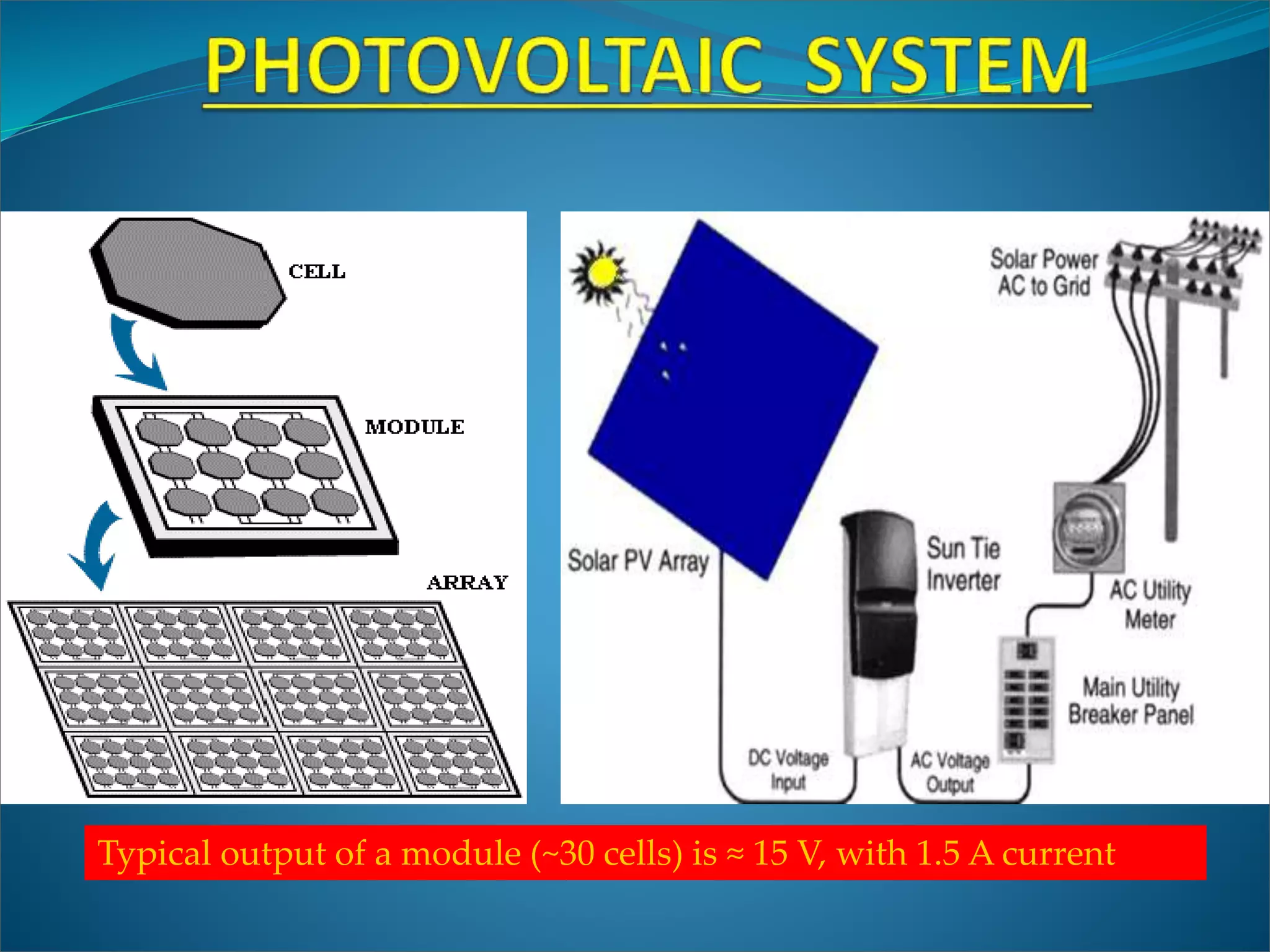

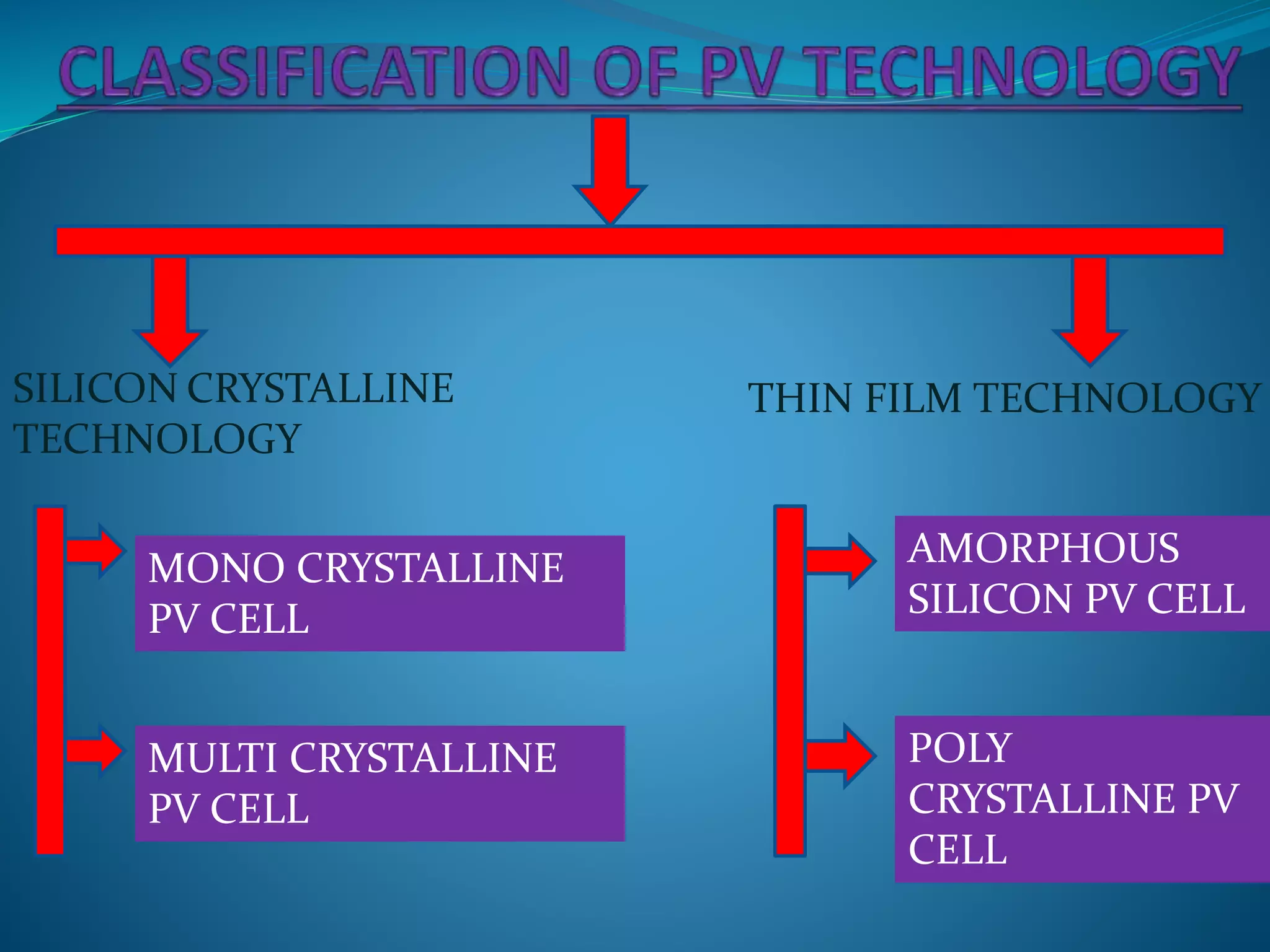

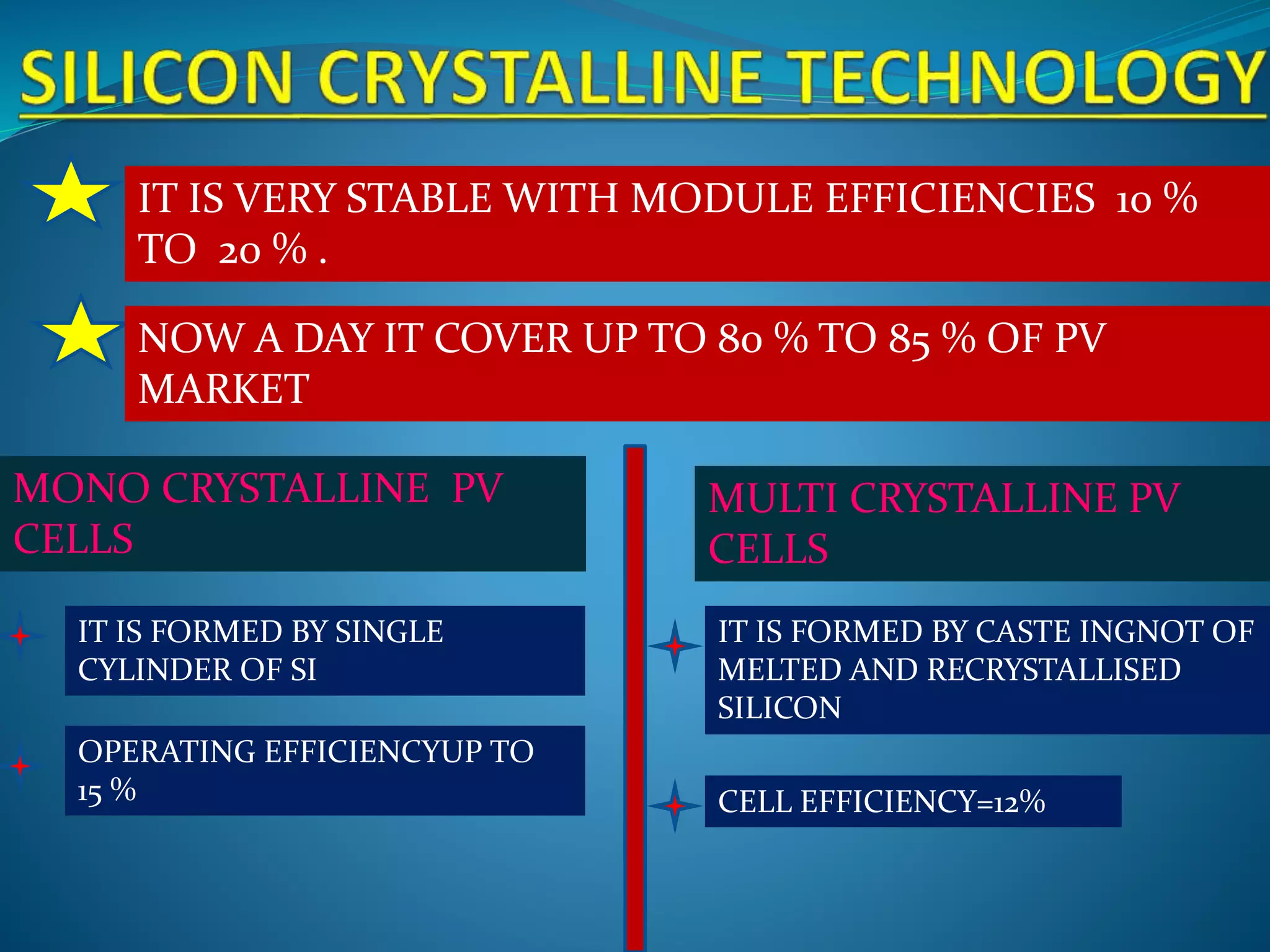

The document discusses the advancements and technological aspects of photovoltaic (PV) cells, highlighting their environmental and economic implications in India and worldwide. It details various types of PV technologies, their efficiencies, market trends, and the significant decline in costs since 1980. The potential for solar energy to contribute to electricity generation and India's goals for solar power are also mentioned, alongside the expected future growth and investment in solar infrastructure.