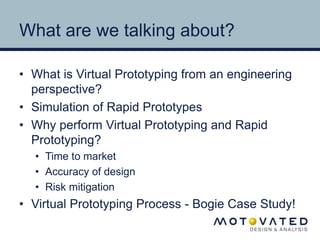

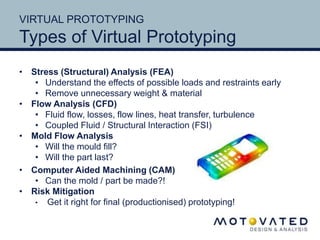

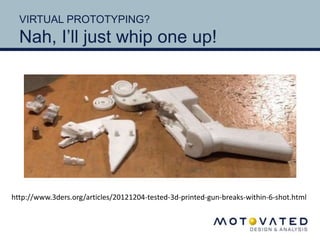

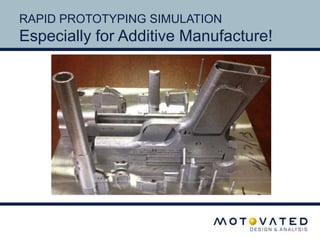

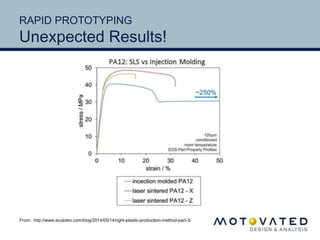

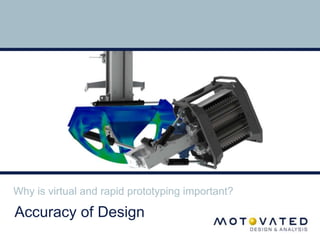

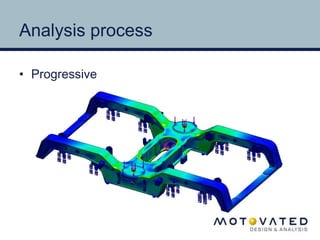

The document discusses the importance of virtual and rapid prototyping in engineering, highlighting their roles in reducing time to market, improving design accuracy, and mitigating risks. It covers various types of virtual prototyping, such as stress analysis and flow analysis, and emphasizes their necessity in ensuring product profitability and success. The authors advocate for integrating these methodologies into the development process to avoid potential pitfalls.