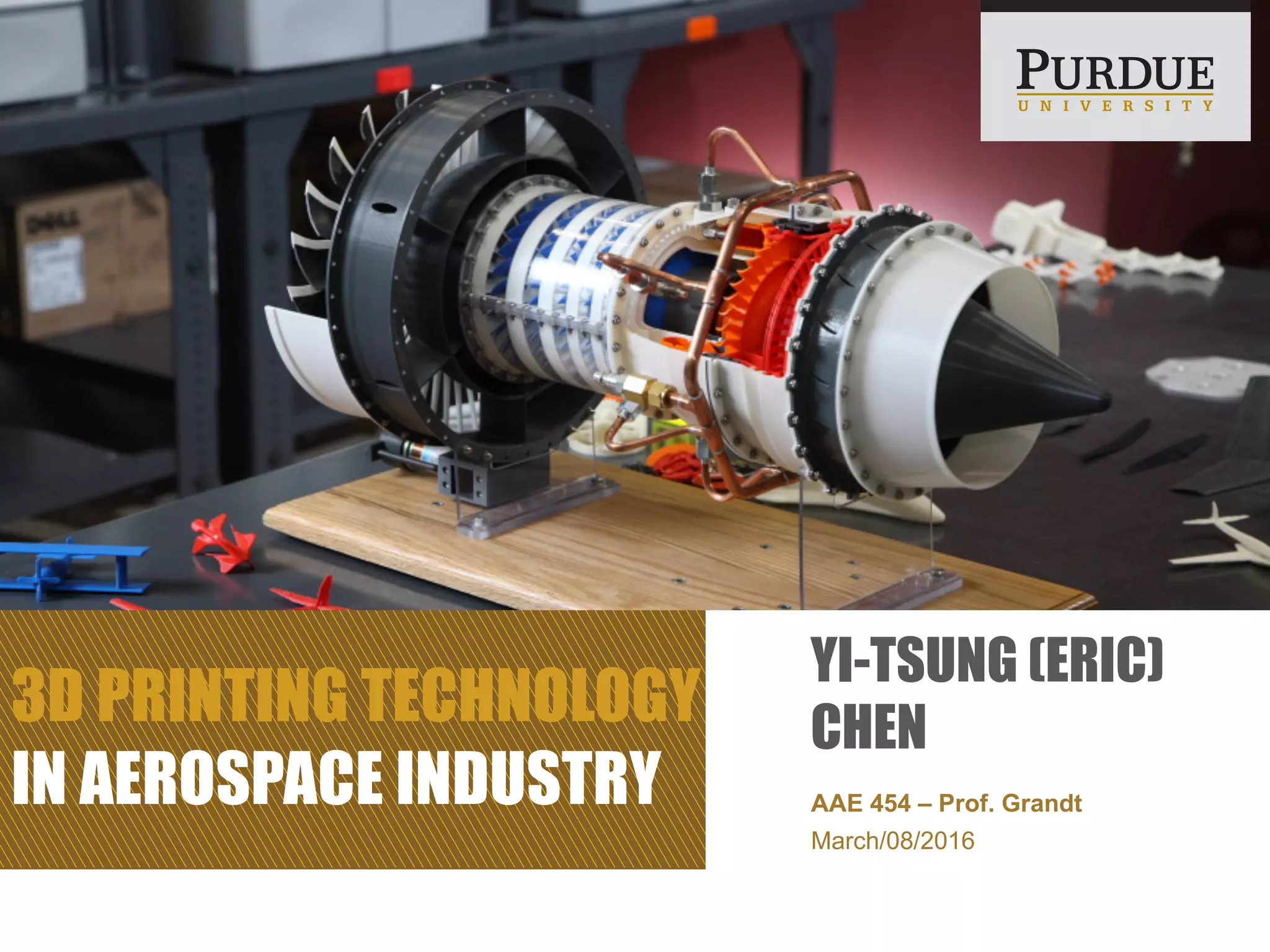

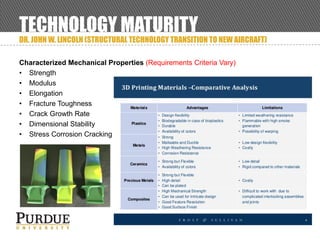

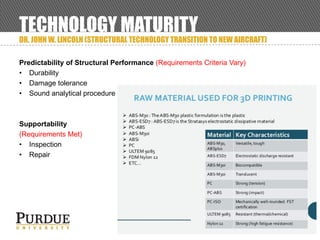

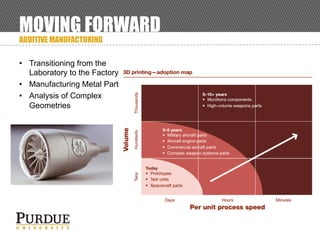

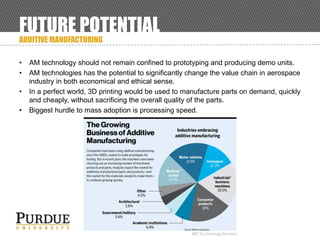

3D printing technology, also known as additive manufacturing, builds objects layer by layer under computer control. It is increasingly being used in the aerospace industry to produce complex parts. While 3D printing allows greater design flexibility and lower costs than traditional manufacturing, wider adoption is limited by issues like speed of production and reliability testing of printed parts. Future advances may enable on-demand printing of replacement parts in space and the mass production of entire aircraft structures with 3D printing.