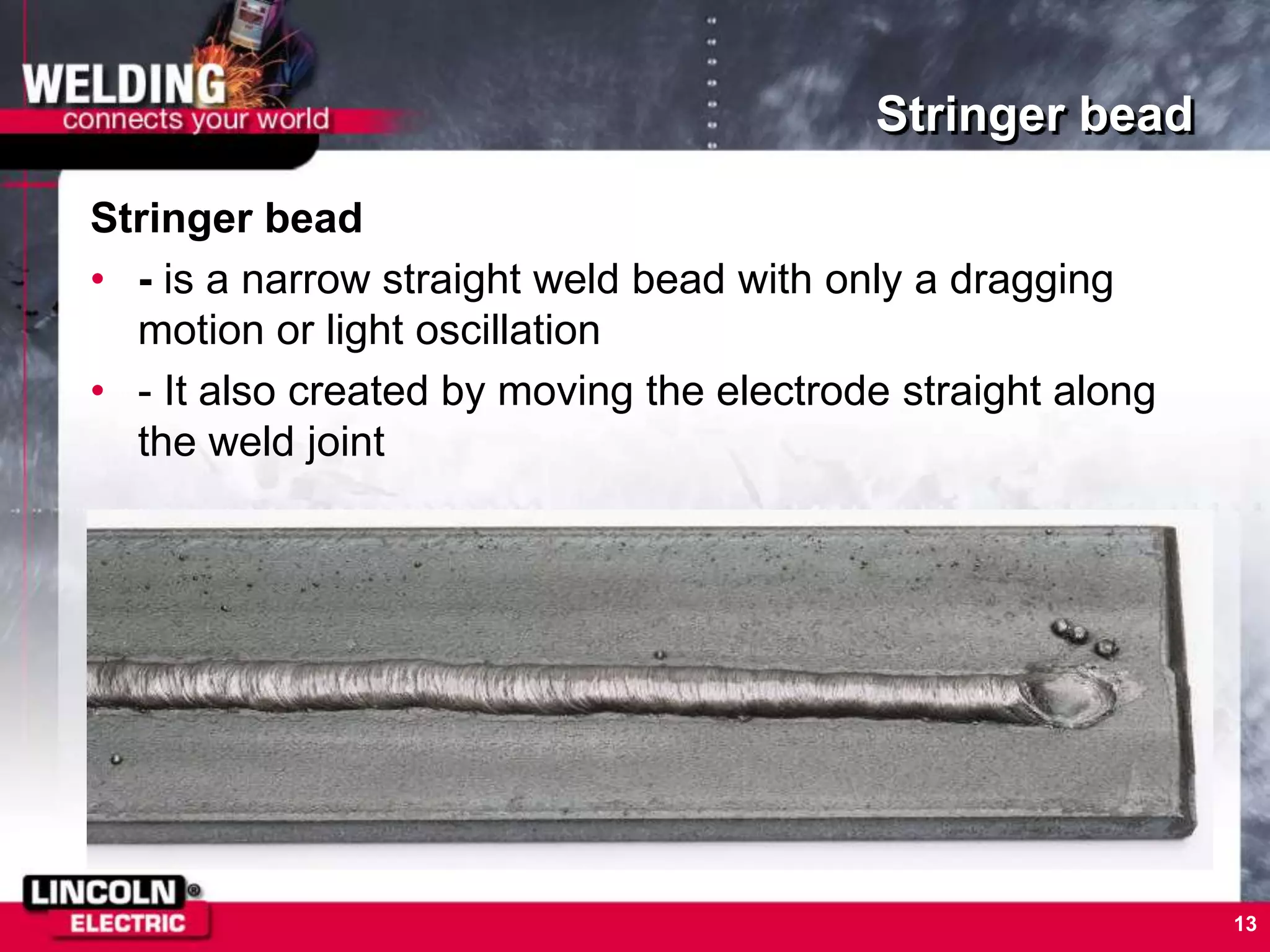

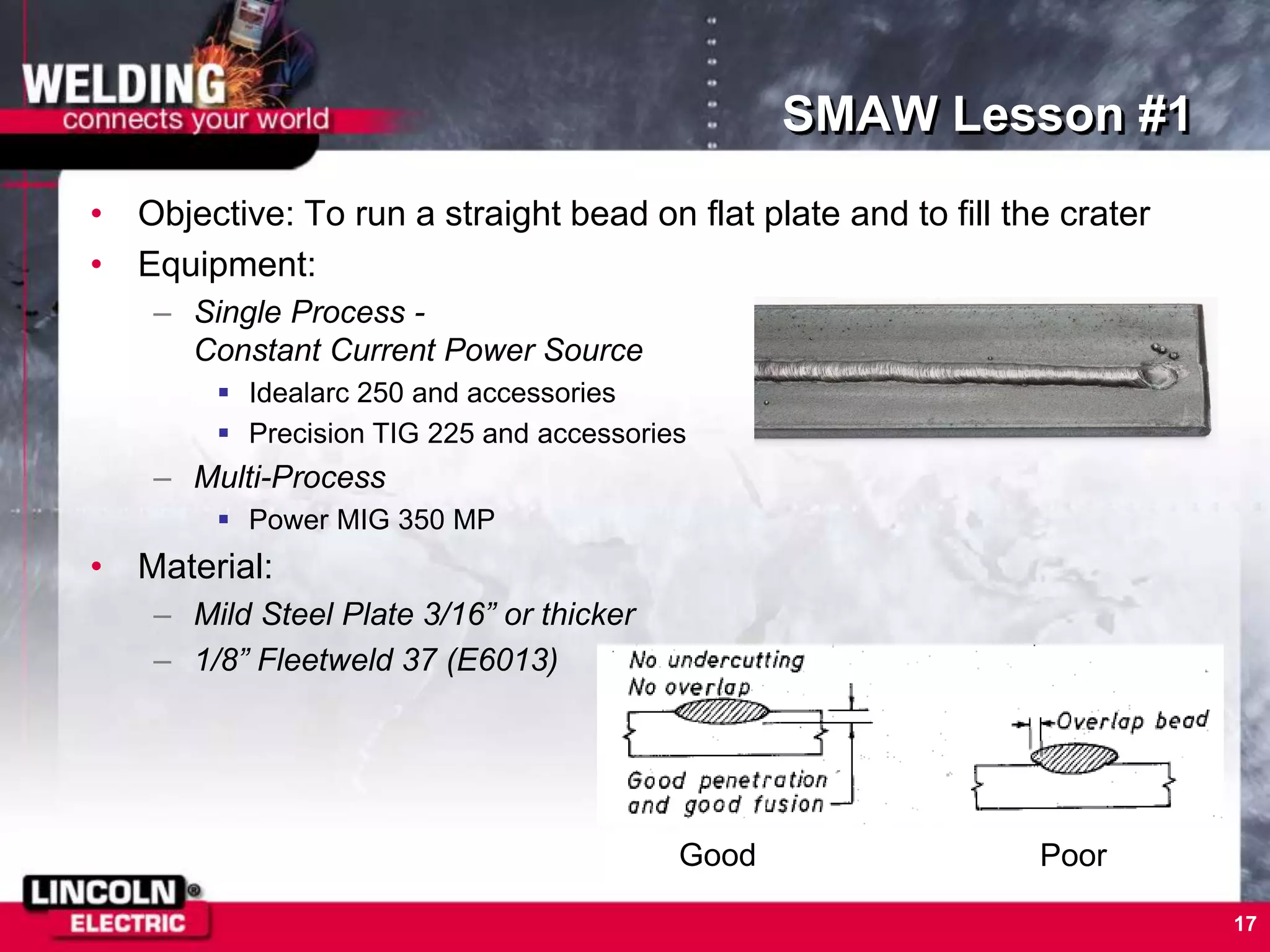

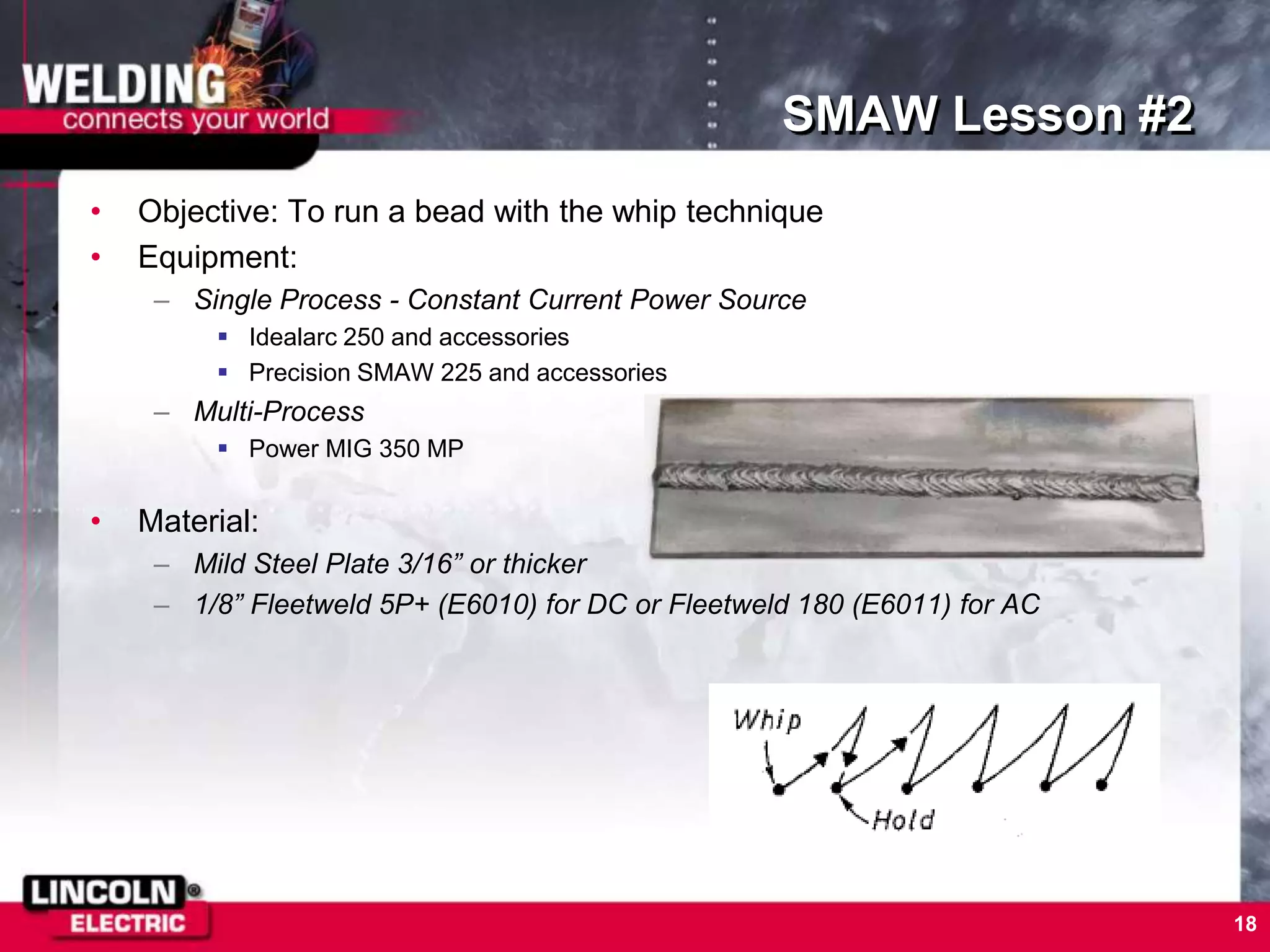

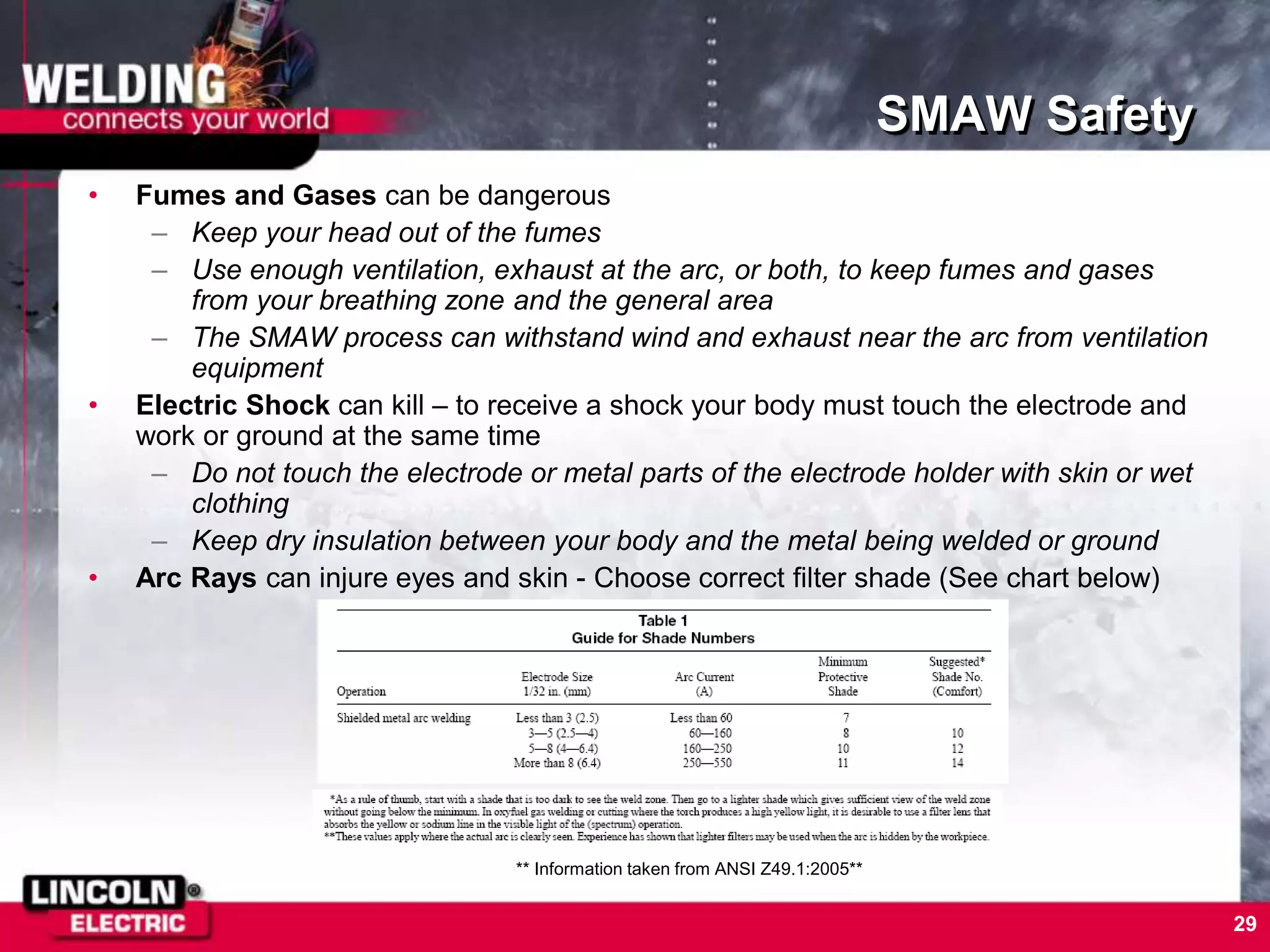

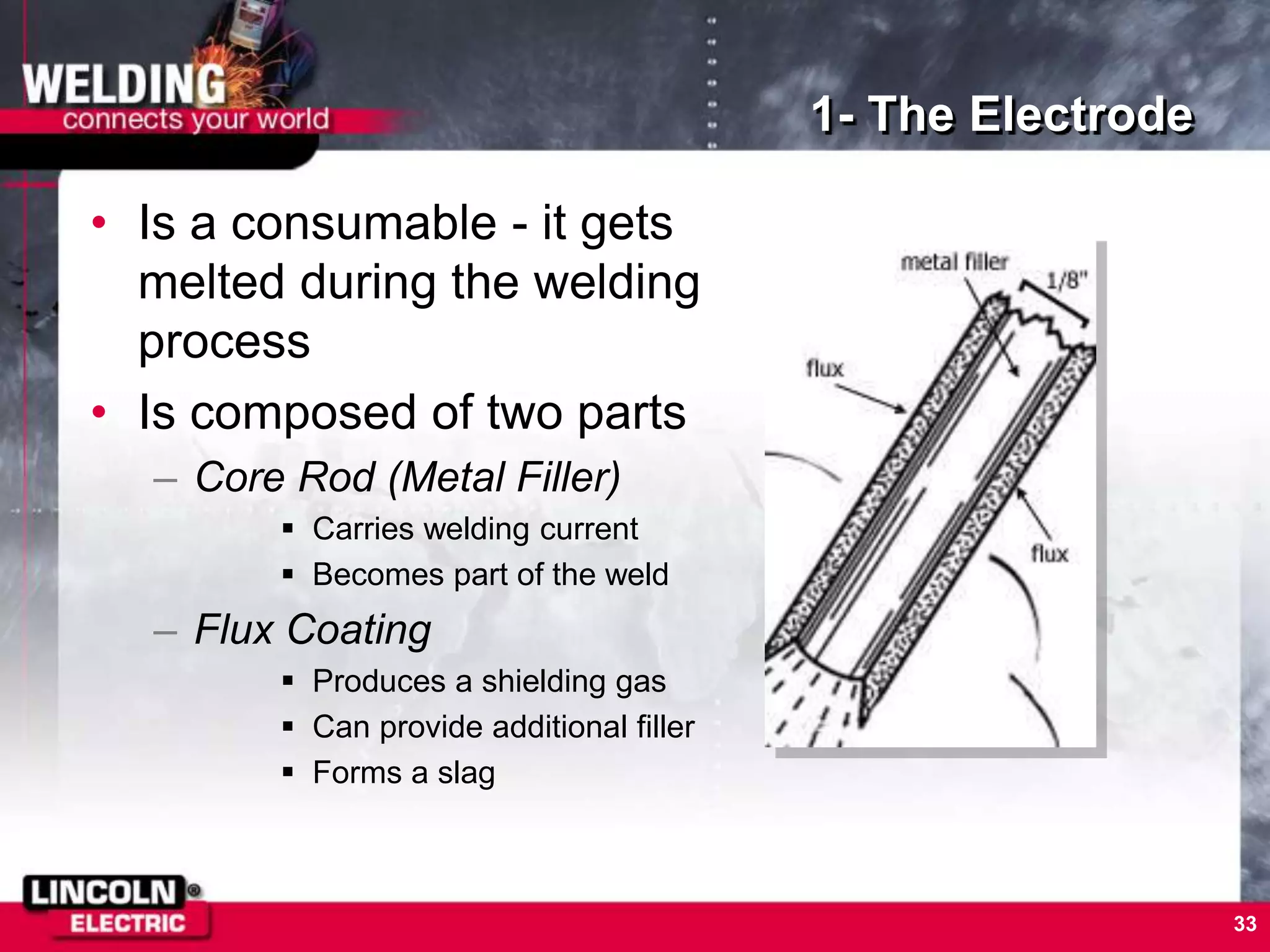

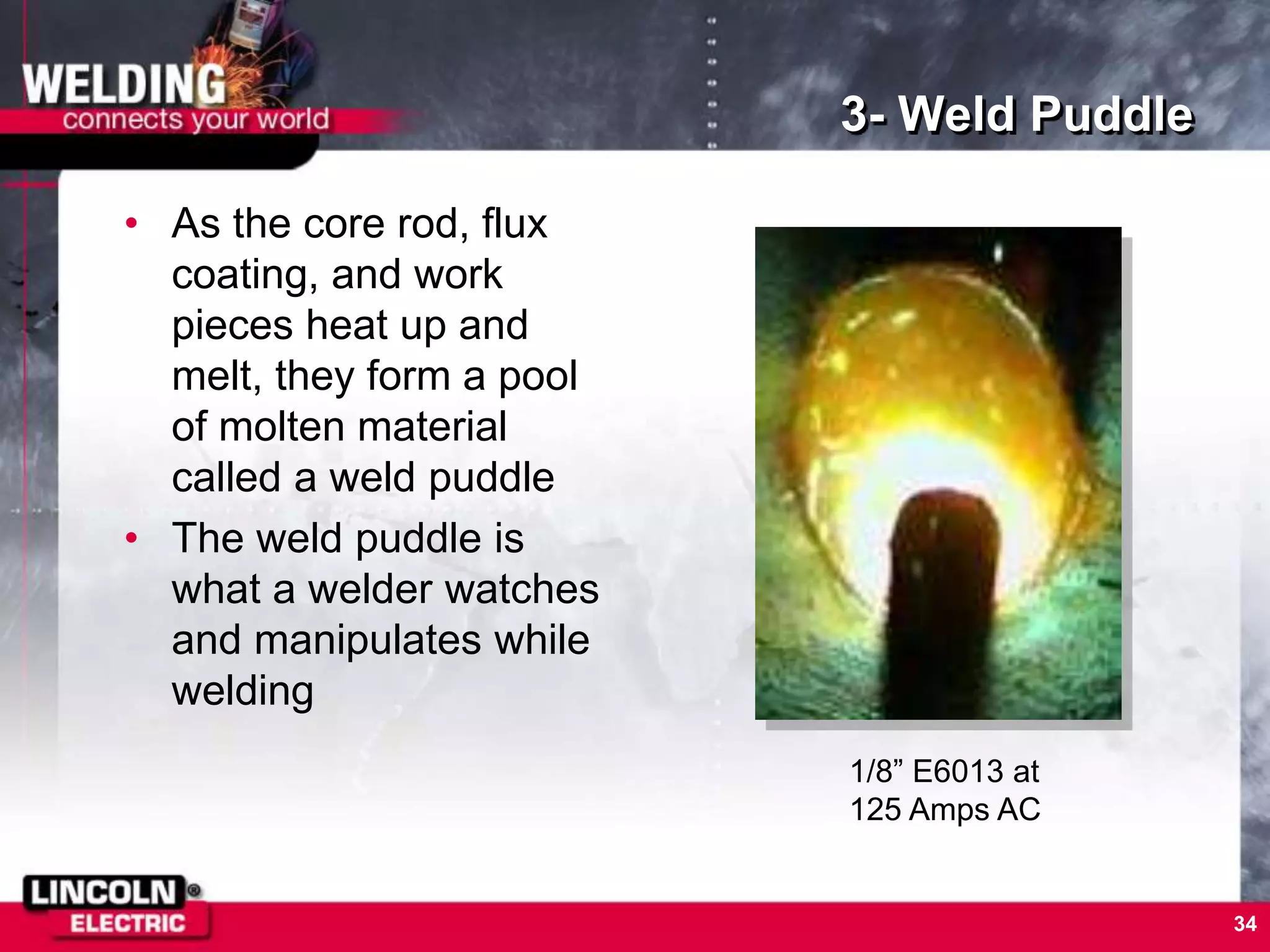

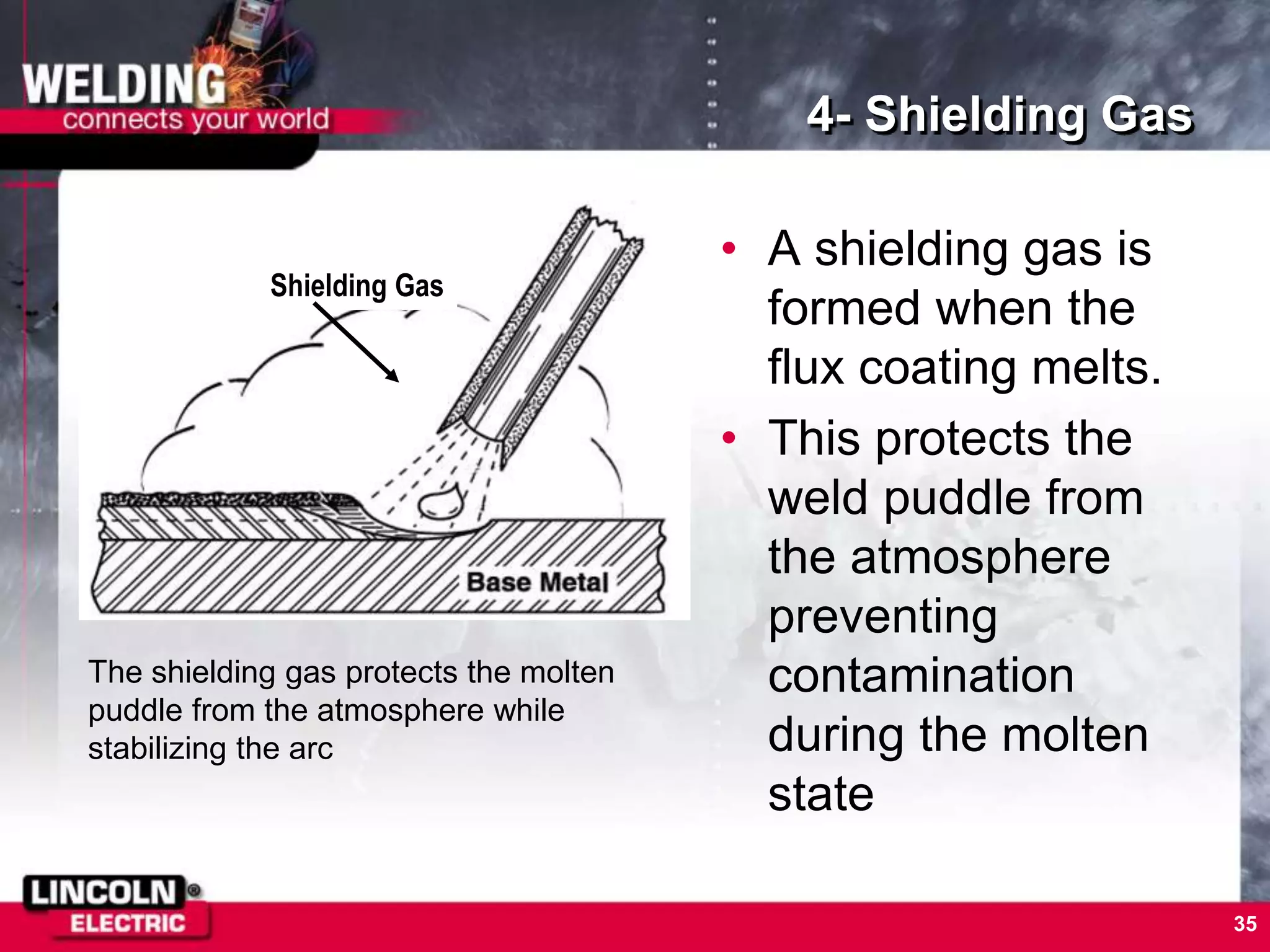

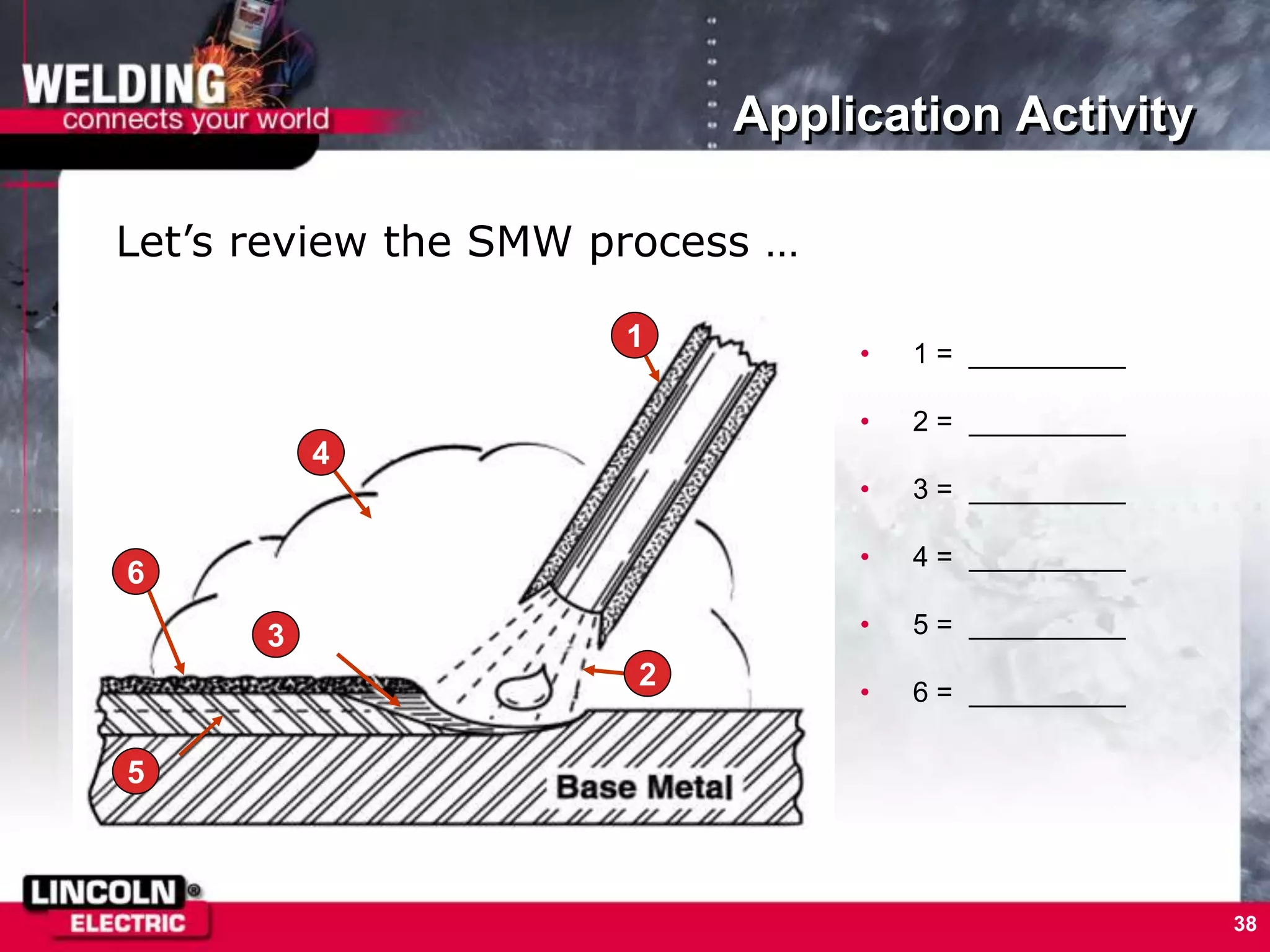

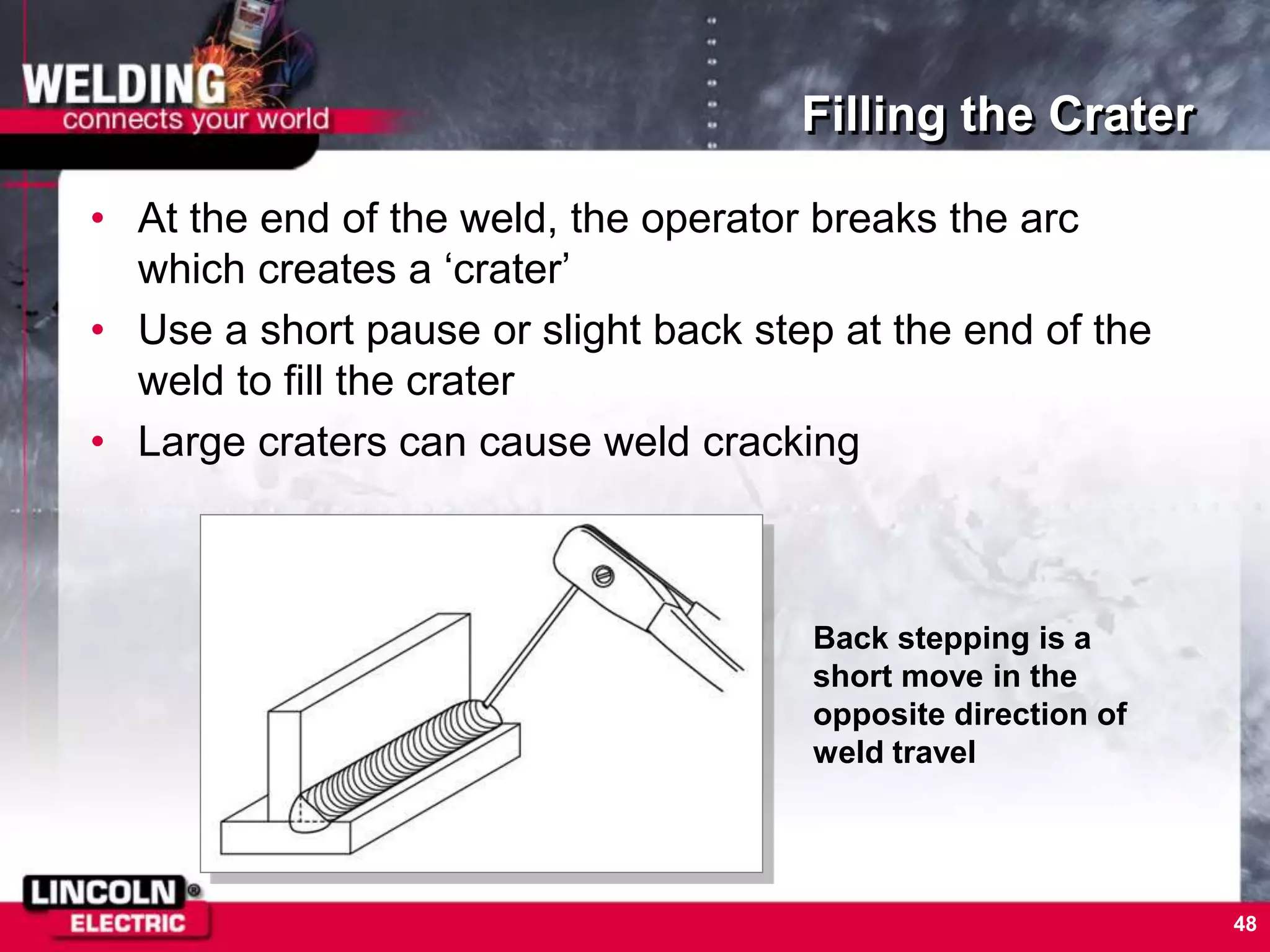

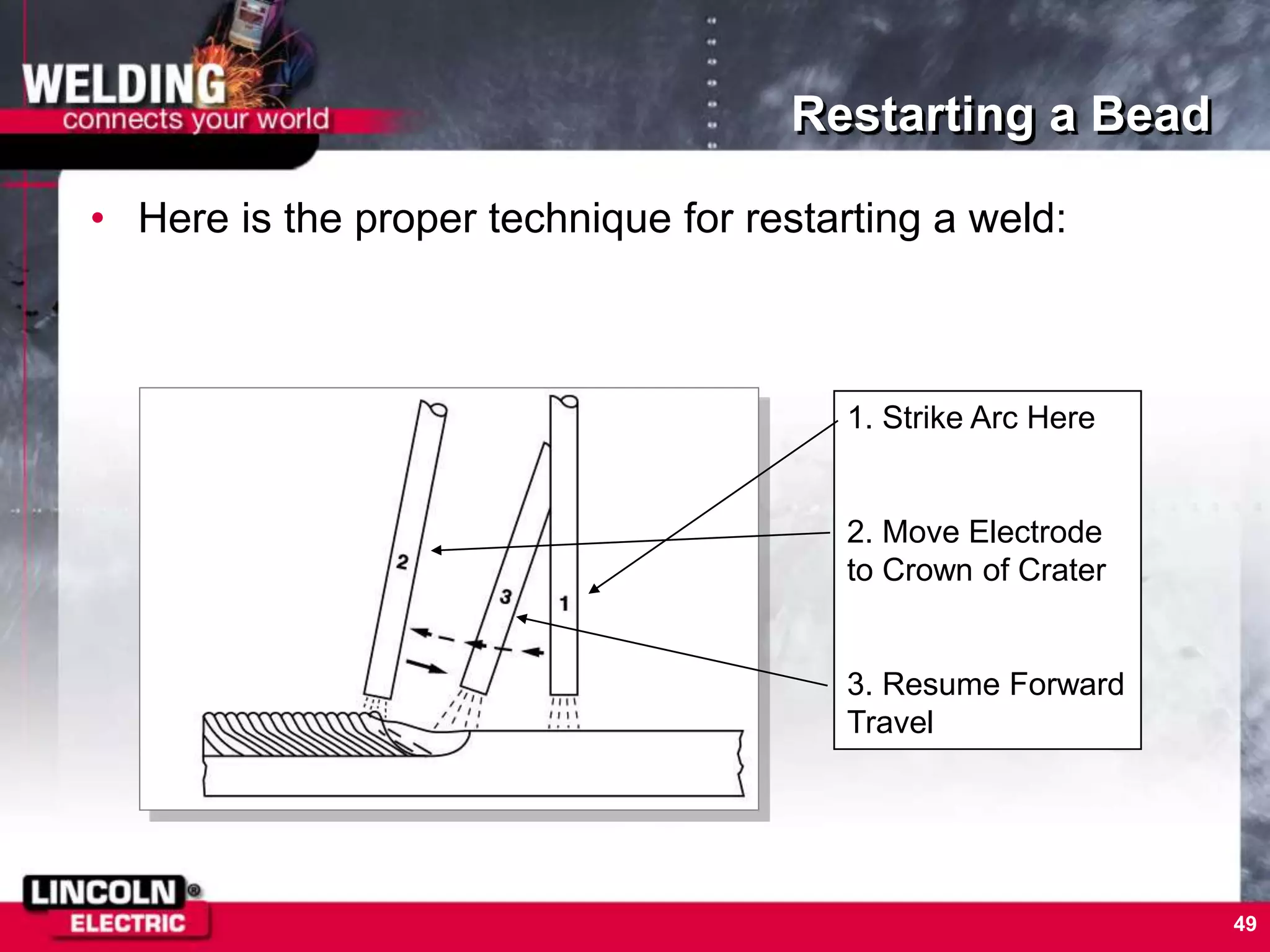

The document provides an overview and guide for teaching Shielded Metal Arc Welding (SMAW) including learning objectives, safety procedures, welding principles, equipment setup, the welding process, troubleshooting techniques, electrode classification, and sample lesson plans. Key topics covered include striking an arc, travel speed, arc length, filler metals, and the advantages and limitations of the SMAW process.