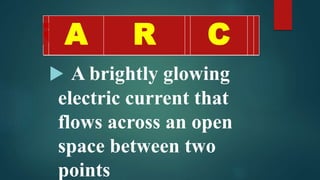

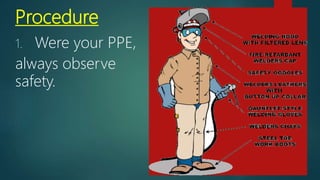

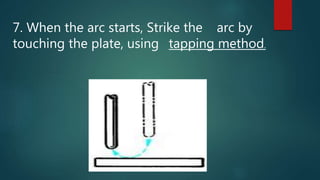

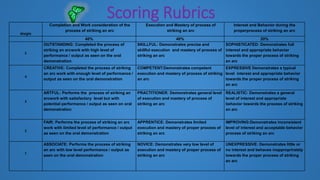

The document provides instructions for the proper procedure of striking an arc when welding. It outlines 11 steps for the procedure, including wearing proper protective equipment, setting up the welding machine, grounding the metal plate, mounting the electrode holder at a 45 degree angle, using the scratching or tapping methods to strike the arc, building a short bead along the edge of the workpiece, chipping slag and brushing beads, and practicing until the arc can be struck freely in the desired location. It emphasizes maintaining safety and properly executing each step of the procedure.