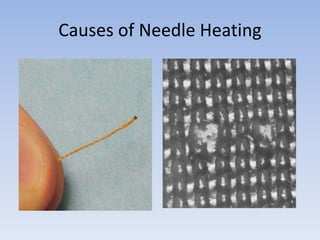

The document discusses sewing problems related to fabric damage, focusing on issues like stitch formation and seam pucker. It identifies causes of damage, including inappropriate needle selection and mechanical damage, while providing remedies such as using proper needle sizes and lubrication. The conclusion emphasizes that improving the sewing process can lead to higher product quality by addressing common faults.