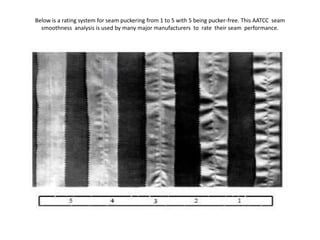

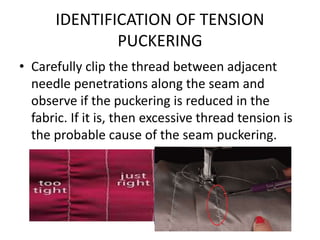

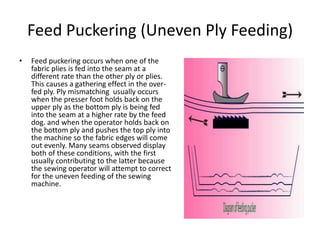

This document provides information on seam puckering, its causes, identification, and solutions. Seam puckering is caused by yarn displacement, tension puckering, uneven ply feeding, and shrinkage differences between materials. Yarn displacement is identified by clipping threads and observing if puckering remains. Tension puckering is identified similarly and is solved by using low elongation thread and light tensions. Uneven ply feeding is identified by cutting the seam and measuring ply lengths and is solved by proper presser foot pressure. Shrinkage puckering is caused by material shrinkage differences and is minimized using components like Perma Core Ultimate thread that have very low or zero shrinkage.