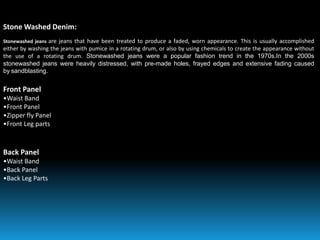

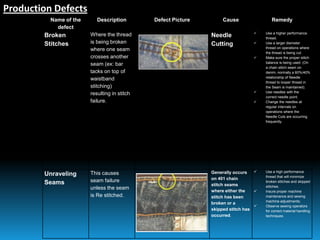

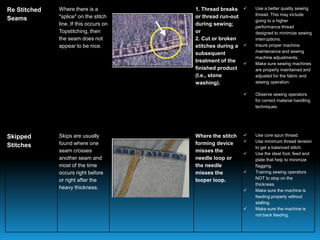

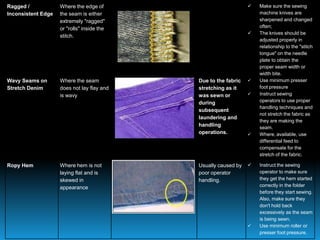

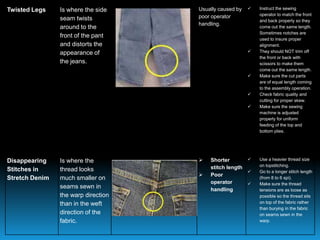

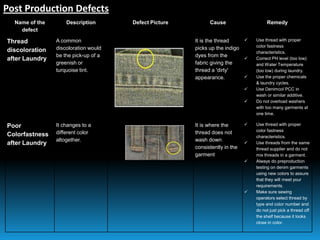

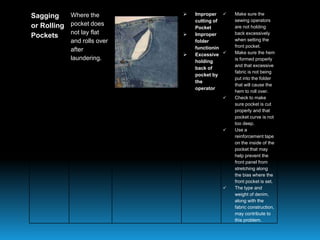

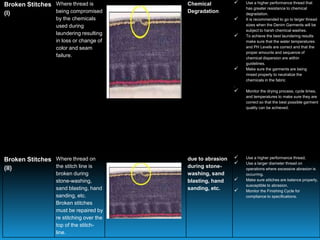

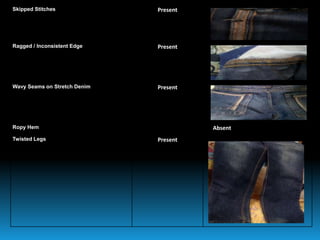

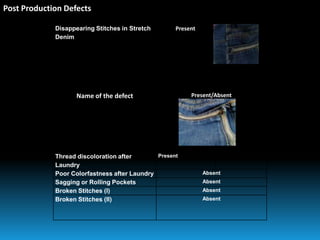

The document provides a summary of quality control processes in the garment industry from raw material sourcing through finished products. It discusses factors that determine quality like performance, reliability and durability. It also outlines common defects at various stages like sewing defects, color defects, sizing defects, and defects during manufacturing. Specific defects in a sample denim trouser are analyzed like re-stitched seams, skipped stitches, ragged edges, wavy seams, and disappearing stitches in stretch denim. Post-production defects from laundering like thread discoloration and broken stitches are also discussed. Remedies for preventing defects during production and finishing are provided.