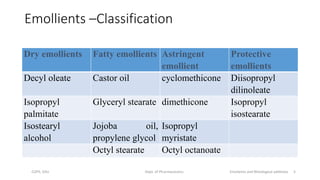

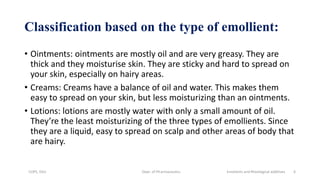

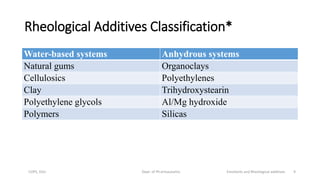

The document discusses the roles and classifications of emollients and rheological additives in cosmetic formulations, highlighting their properties, applications, and benefits for skin health. Emollients, primarily lipids and oils, provide moisturizing and protective functions, while rheological additives enhance product stability and performance. The text outlines various types of emollients, their classifications based on moisture content, and the significance of rheological additives in modifying viscosity and texture in personal care products.