This document discusses sedimentation and settling velocity calculations. It provides:

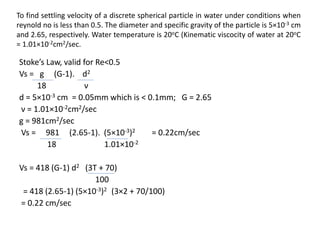

1) A calculation of settling velocity for a spherical particle using Stokes' Law, finding a velocity of 0.22 cm/sec.

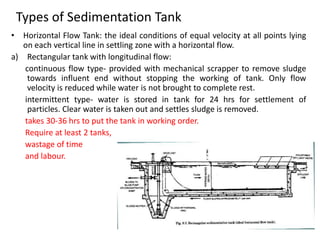

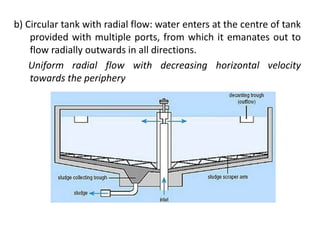

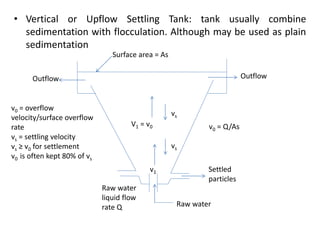

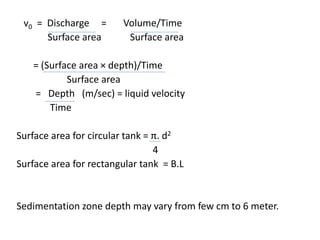

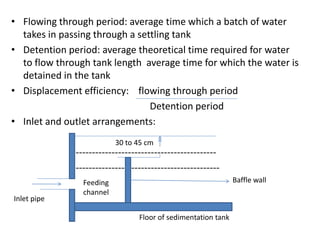

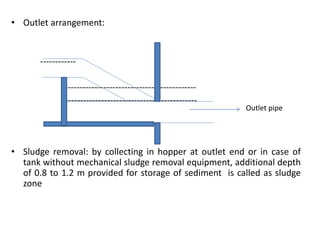

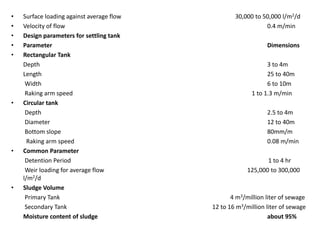

2) An overview of horizontal flow and vertical upflow sedimentation tank designs and operating parameters.

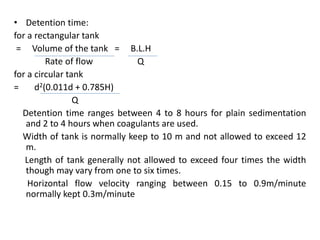

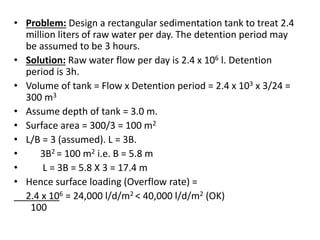

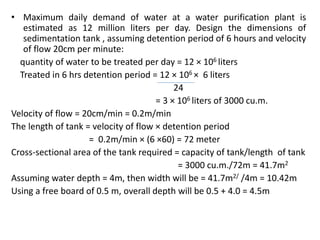

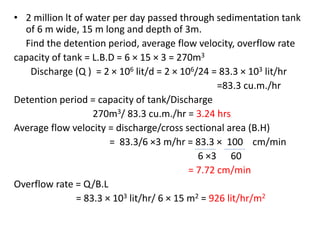

3) Examples of calculations for sedimentation tank sizing and design parameters like detention time and surface loading rates.