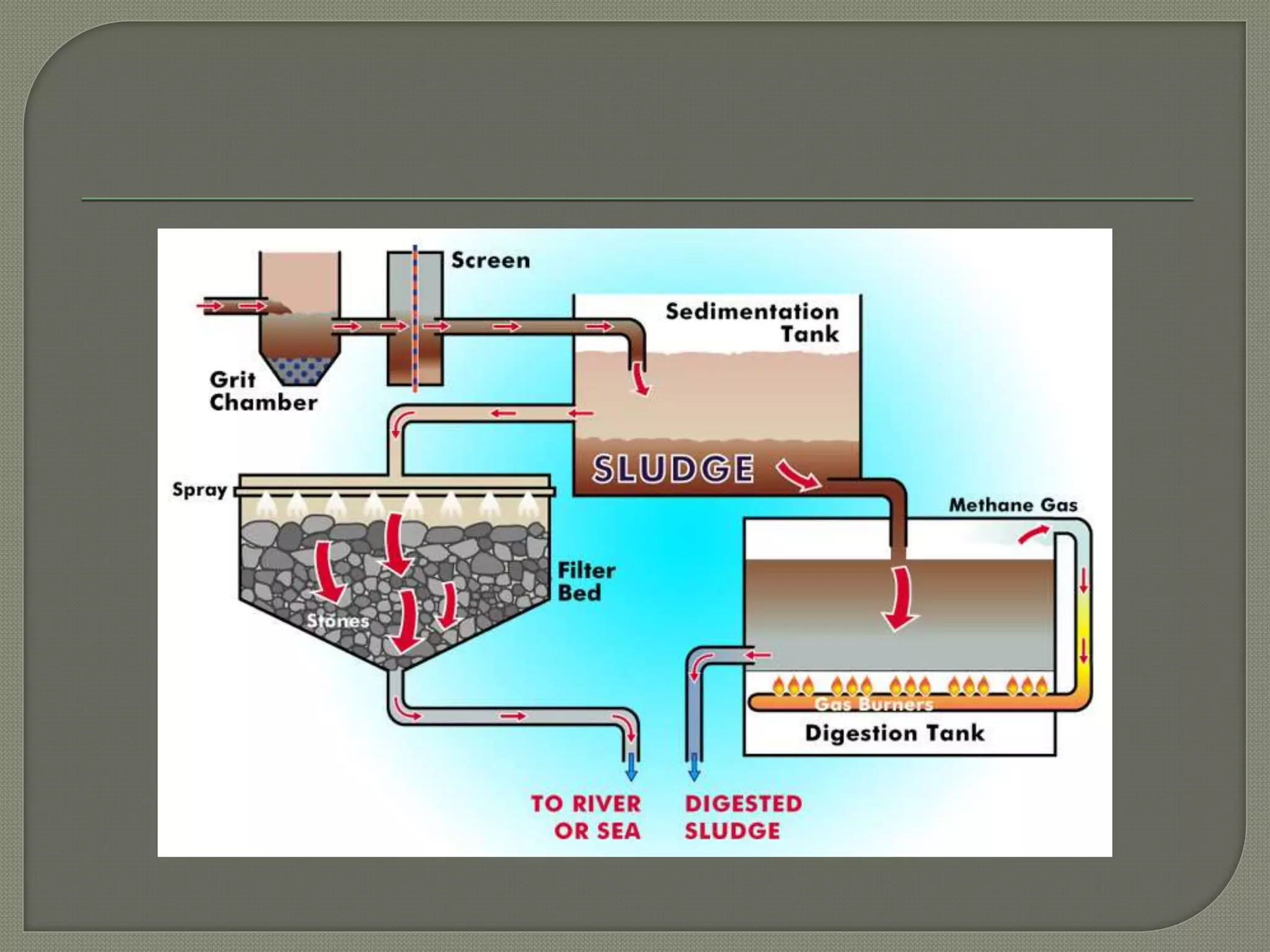

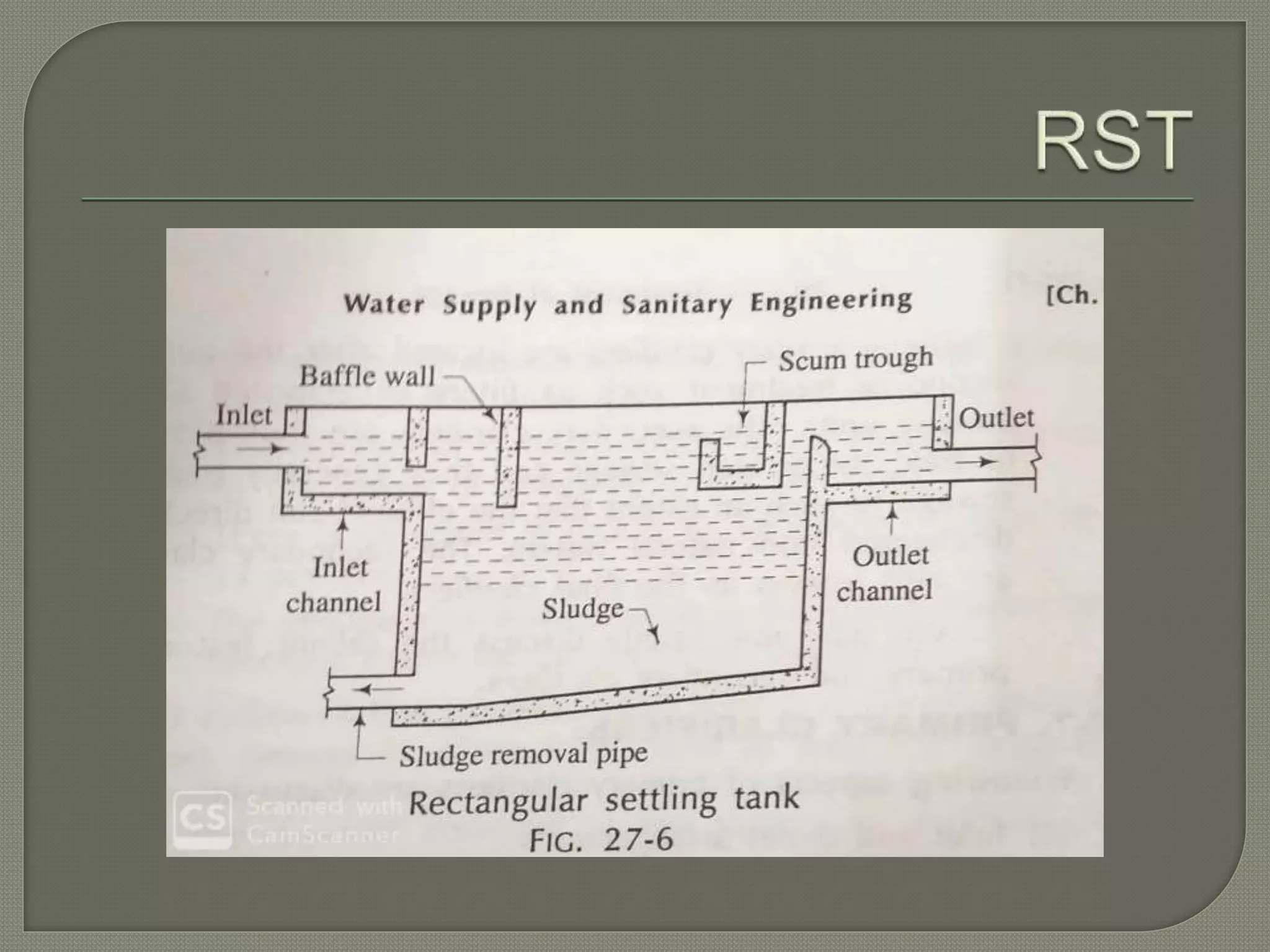

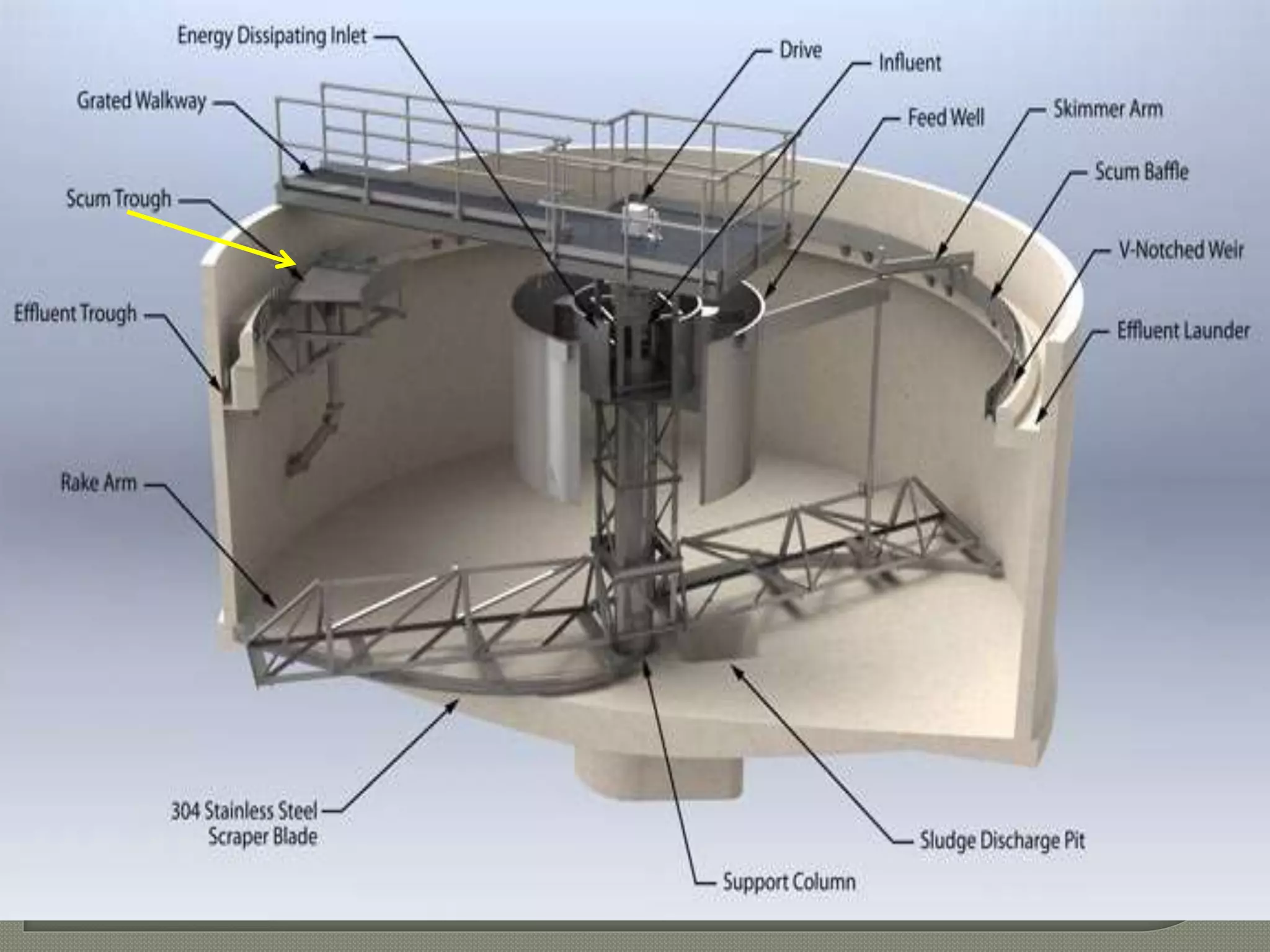

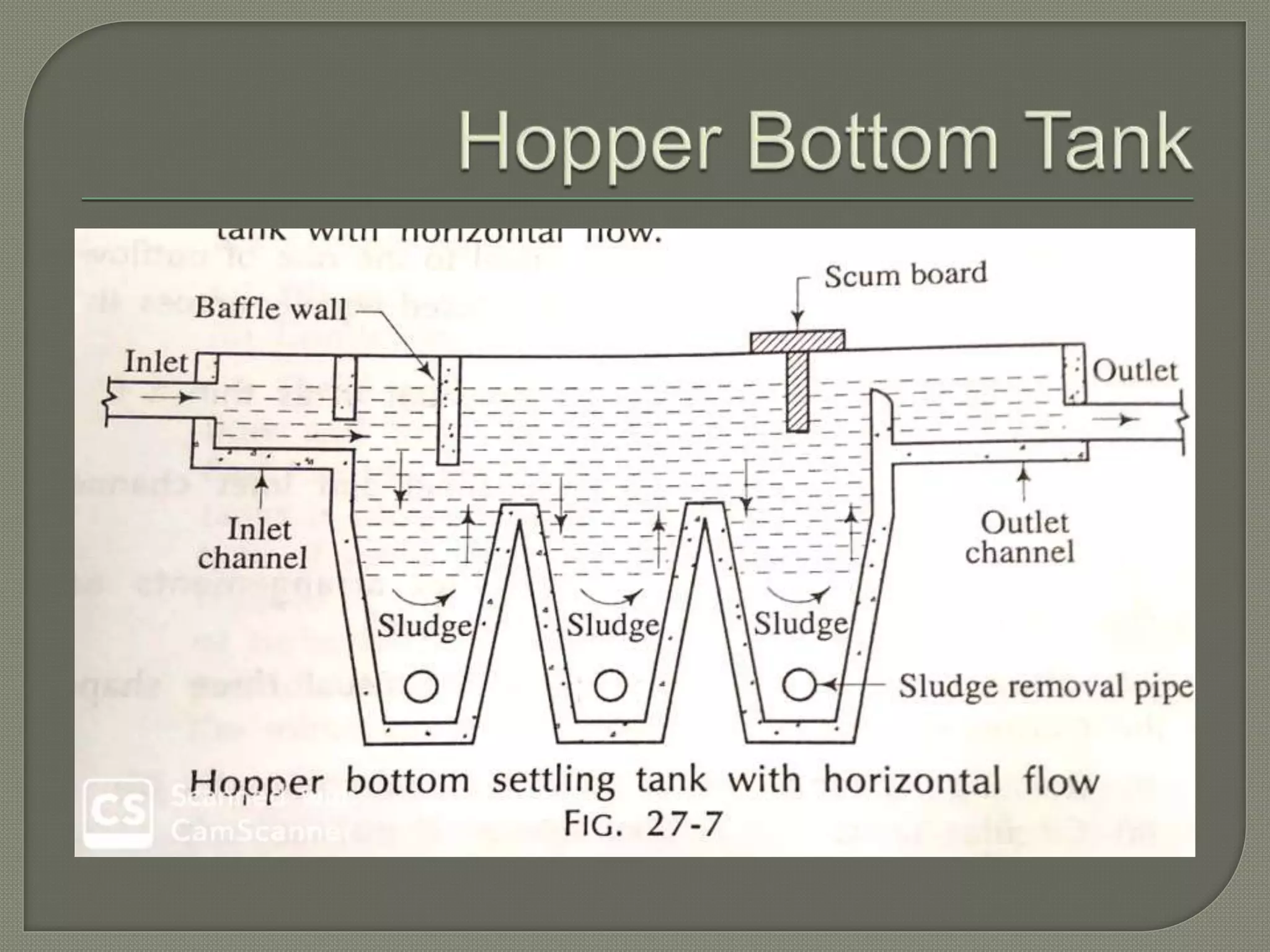

Sedimentation tanks, also known as clarifiers, are used in sewage treatment plants to reduce the strength of sewage through sedimentation. The key processes are similar to water treatment plants, with some minor modifications. Sedimentation reduces settleable solids in sewage by 80-90% and biochemical oxygen demand by 30-35%, producing effluent that is suitable for further treatment. Clarifiers are either primary or secondary. Primary clarifiers directly treat raw sewage while secondary clarifiers treat effluent from secondary treatment units like filters. Common tank designs include rectangular, circular and hopper bottom tanks. Design considerations include inlet/outlet arrangements, capacity, scum removal, and maintaining equal inflow/out