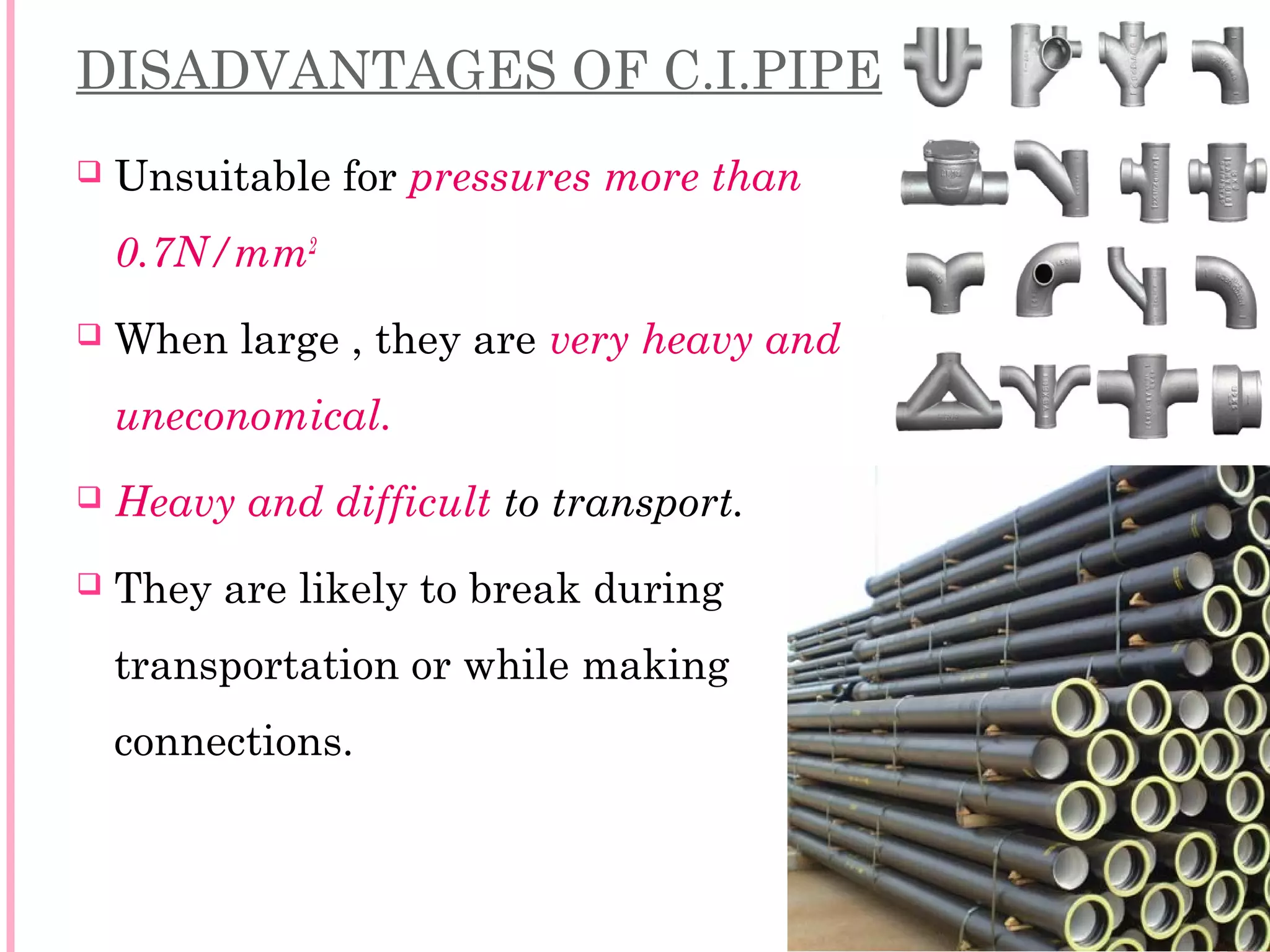

This document discusses various types of pressure pipes used in water supply systems. The main types discussed are cast iron pipes, steel pipes, reinforced cement concrete pipes, hume steel pipes, vitrified clay pipes, and asbestos cement pipes. For each type, the document outlines the material properties, sizes available, joining methods, advantages, and disadvantages. Cast iron pipes are described as moderately priced and durable but heavy. Steel pipes are presented as strong but corrosive. Reinforced cement concrete pipes have a long lifespan but are difficult to repair.