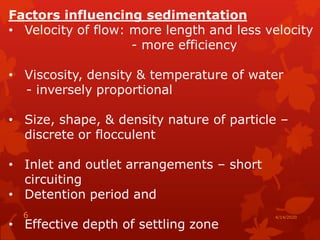

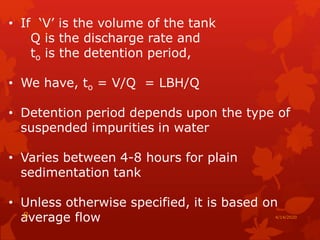

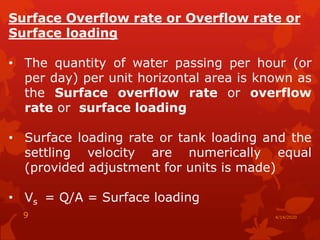

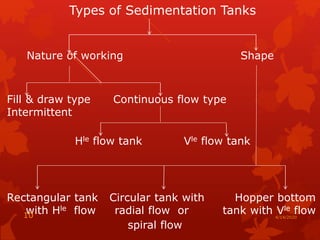

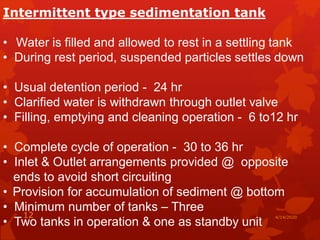

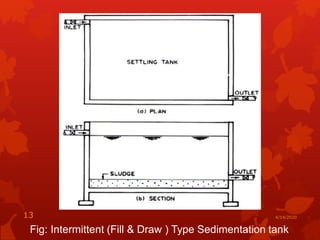

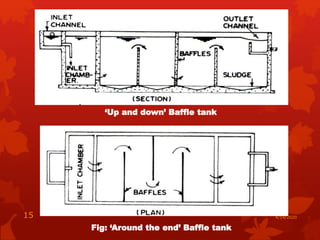

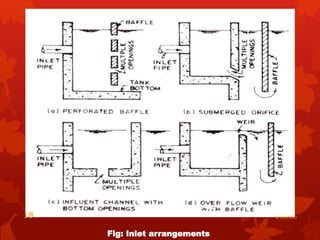

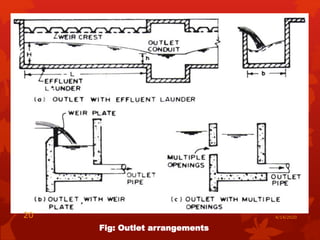

Sedimentation is the process of separating suspended particles from water through gravitational settling, and involves reducing the velocity of water flow in sedimentation tanks to allow particles to settle to the bottom. Sedimentation can be plain or chemically assisted, and factors like tank design, flow rate, and particle characteristics determine settling efficiency. Various tank designs and inlet/outlet configurations aim to optimize detention time and minimize short-circuiting for effective sedimentation.