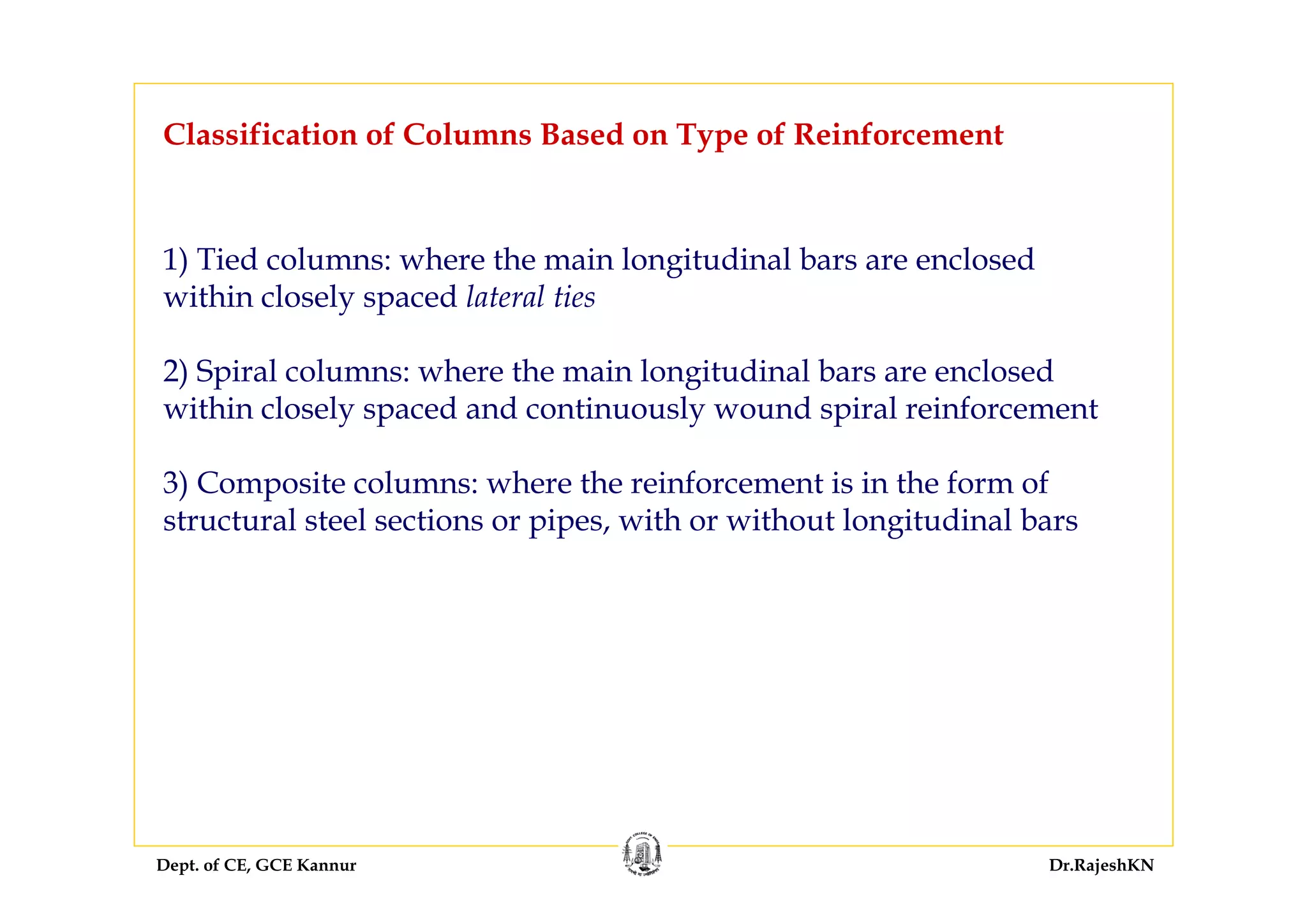

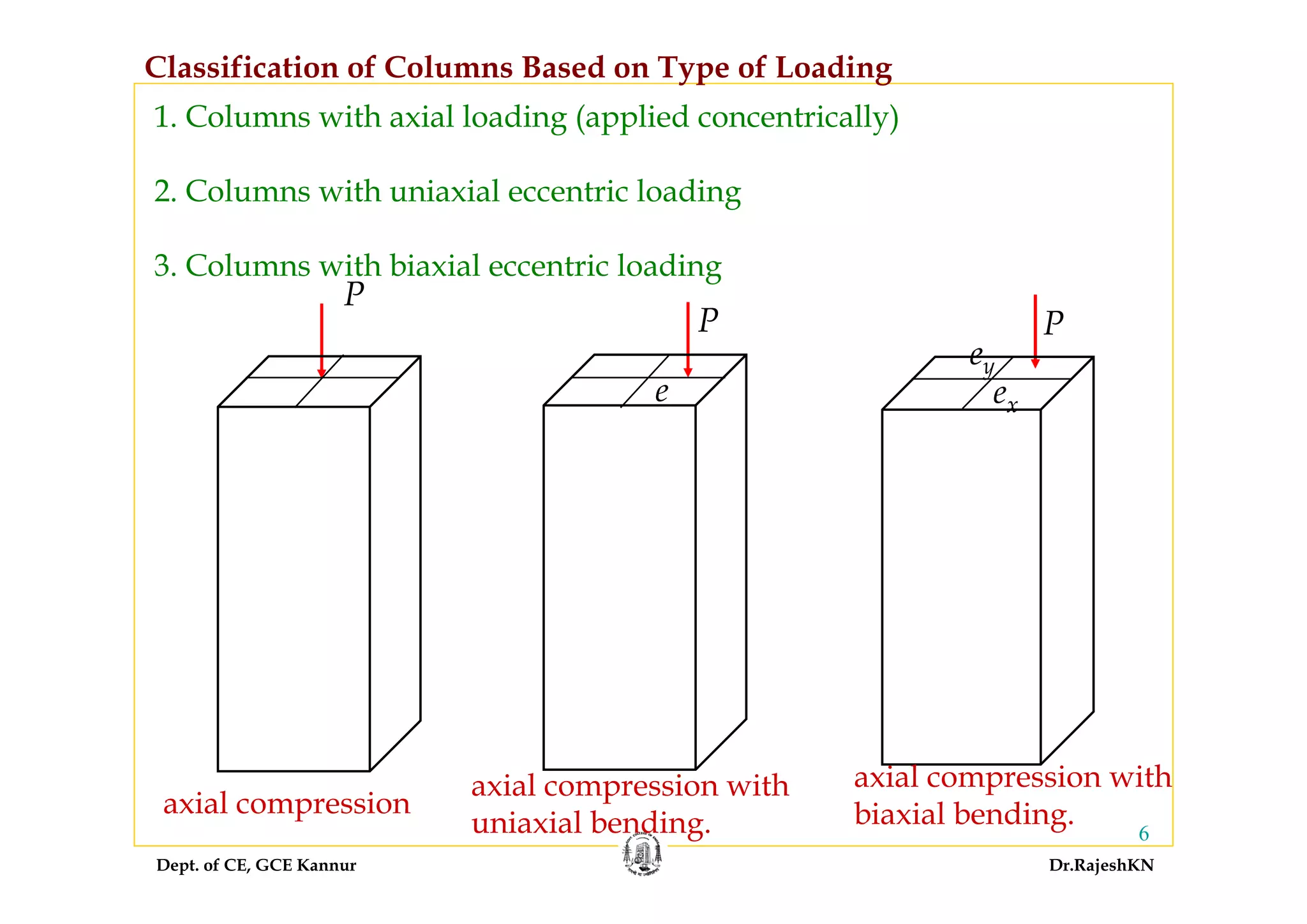

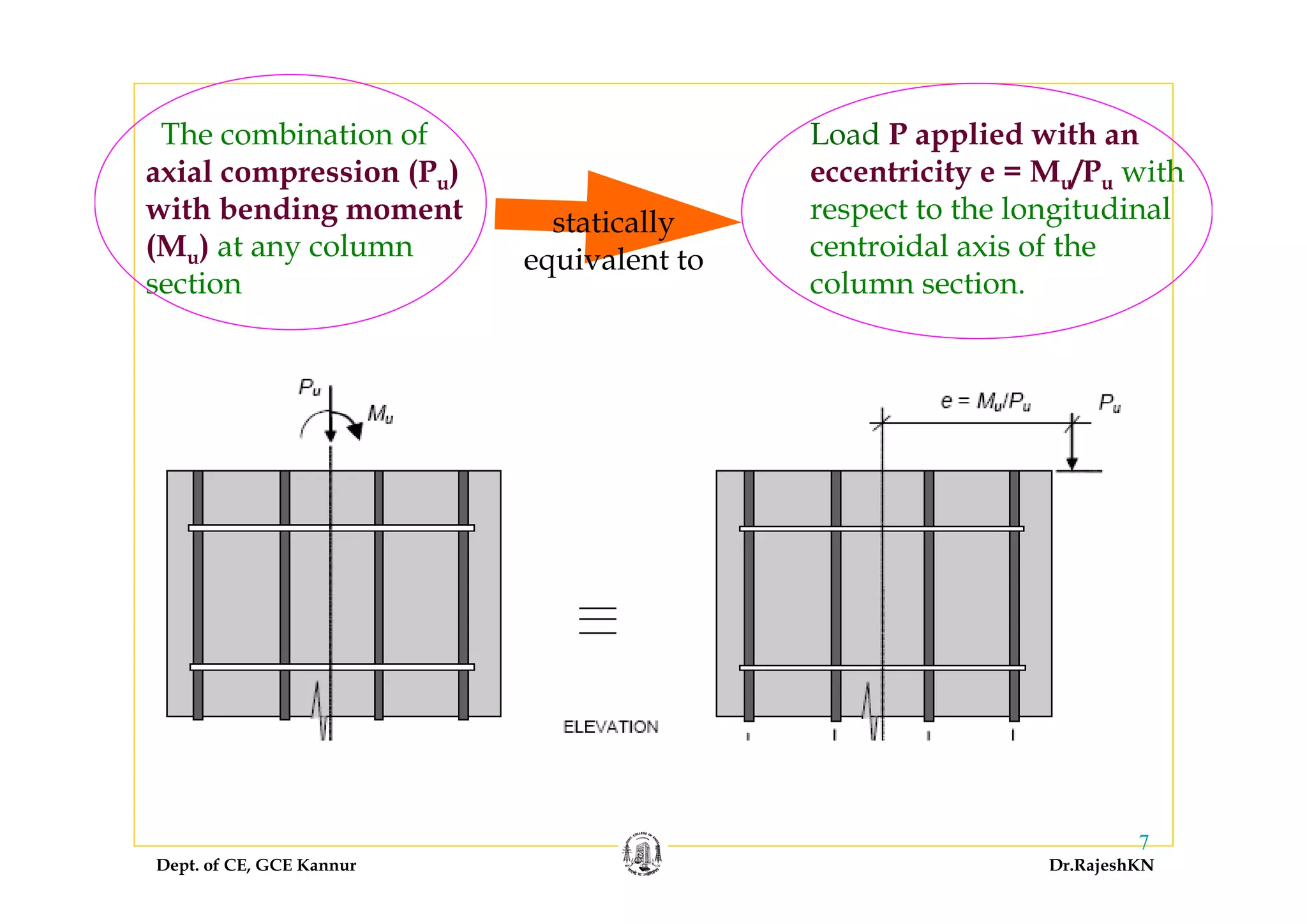

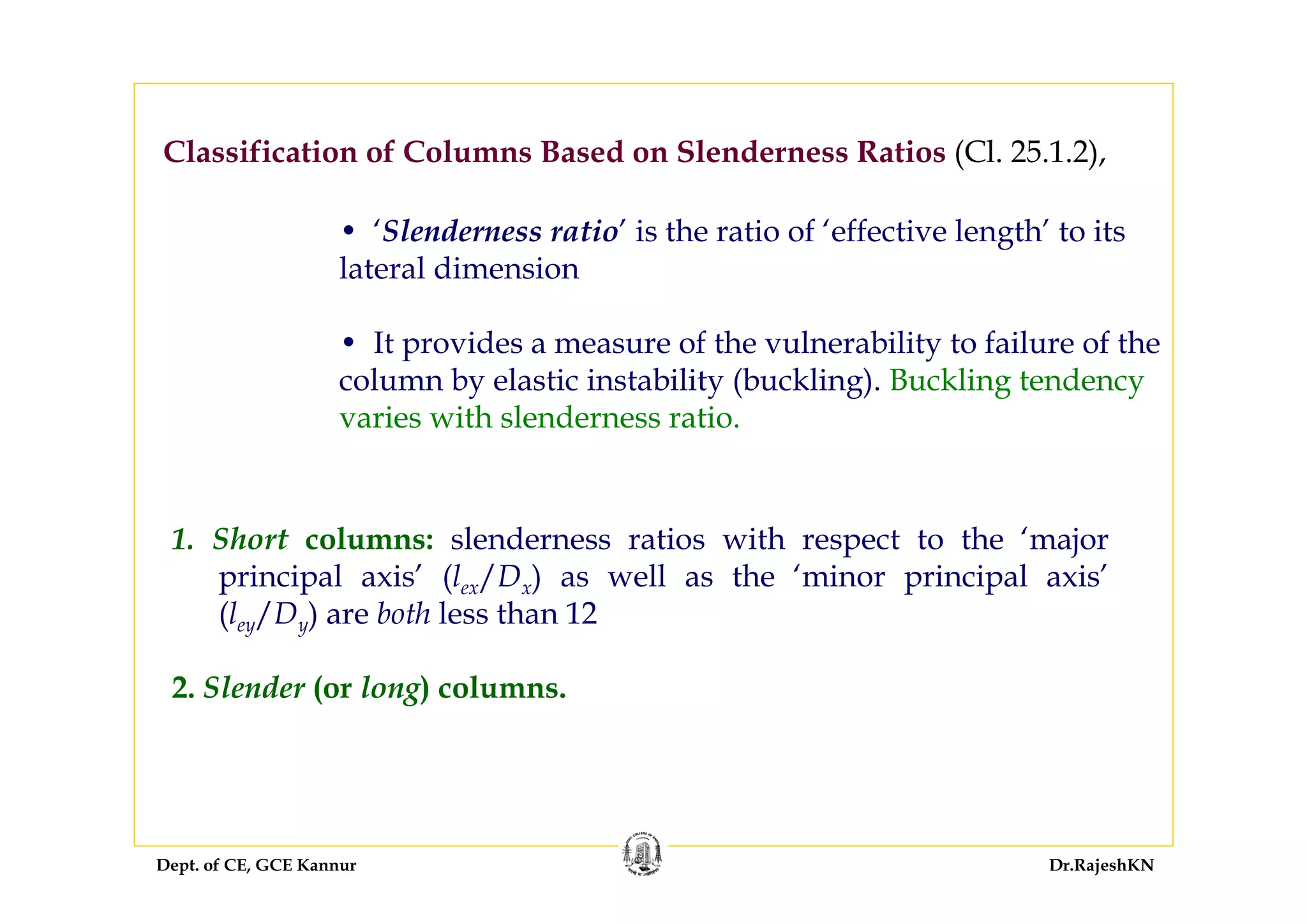

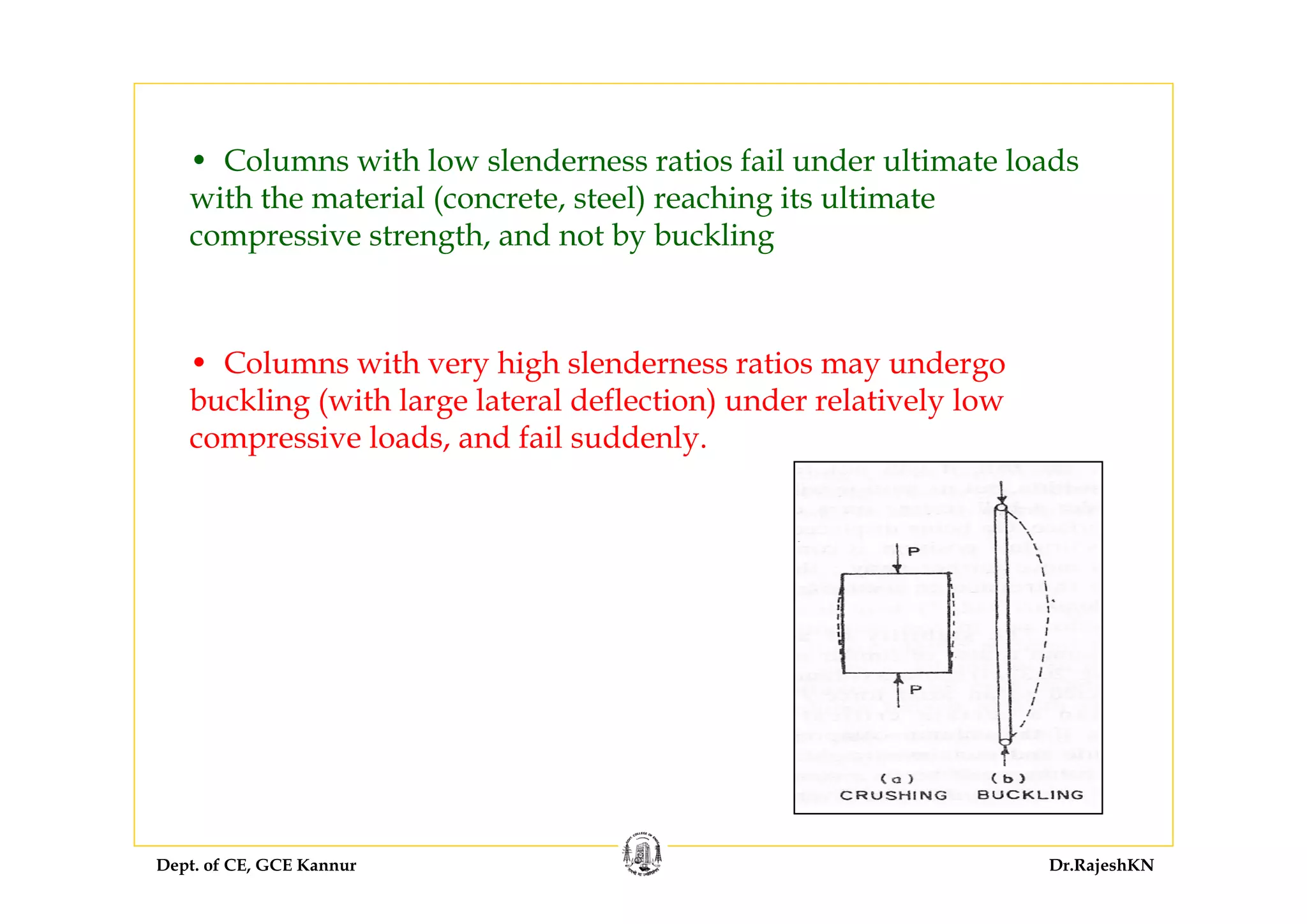

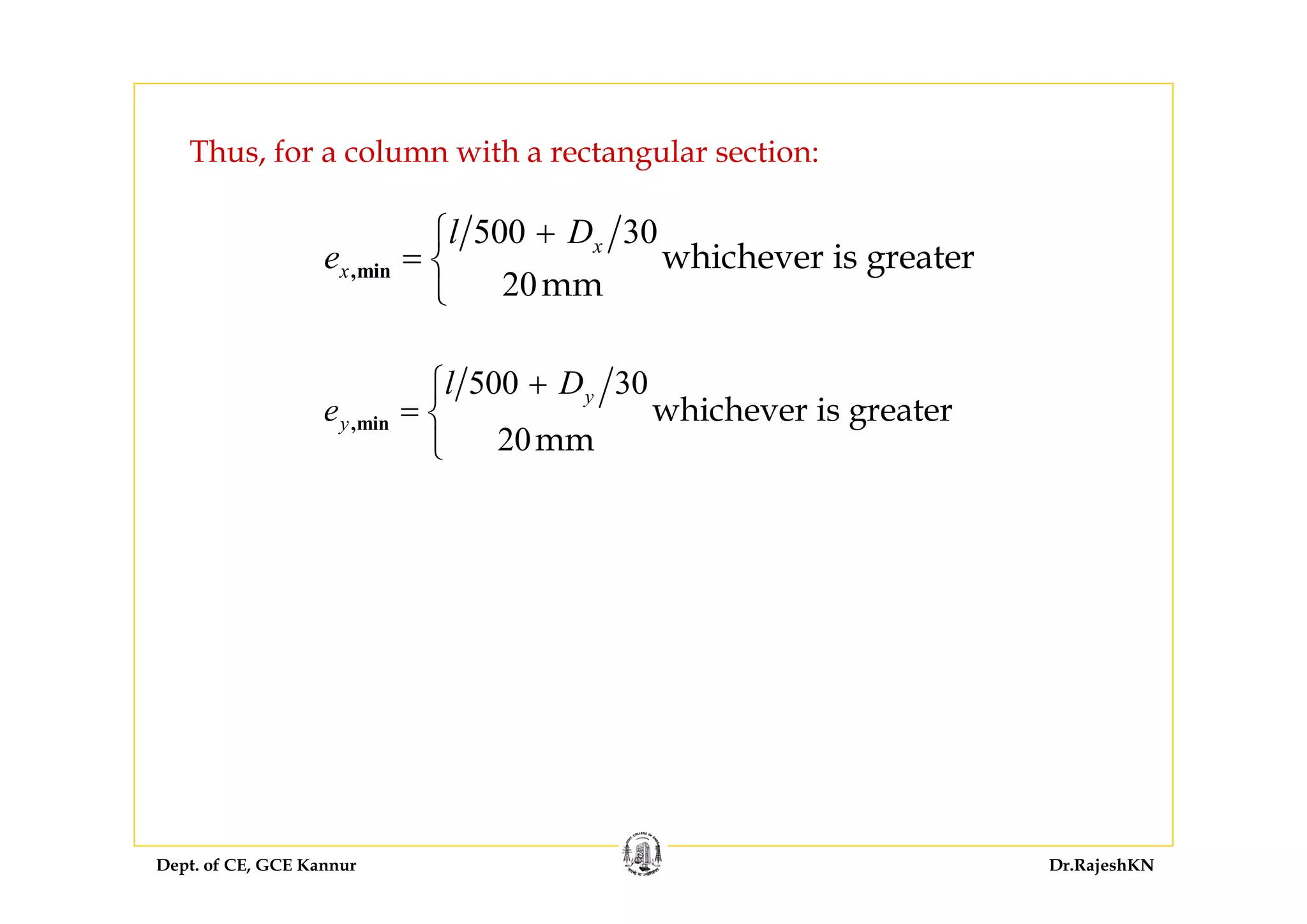

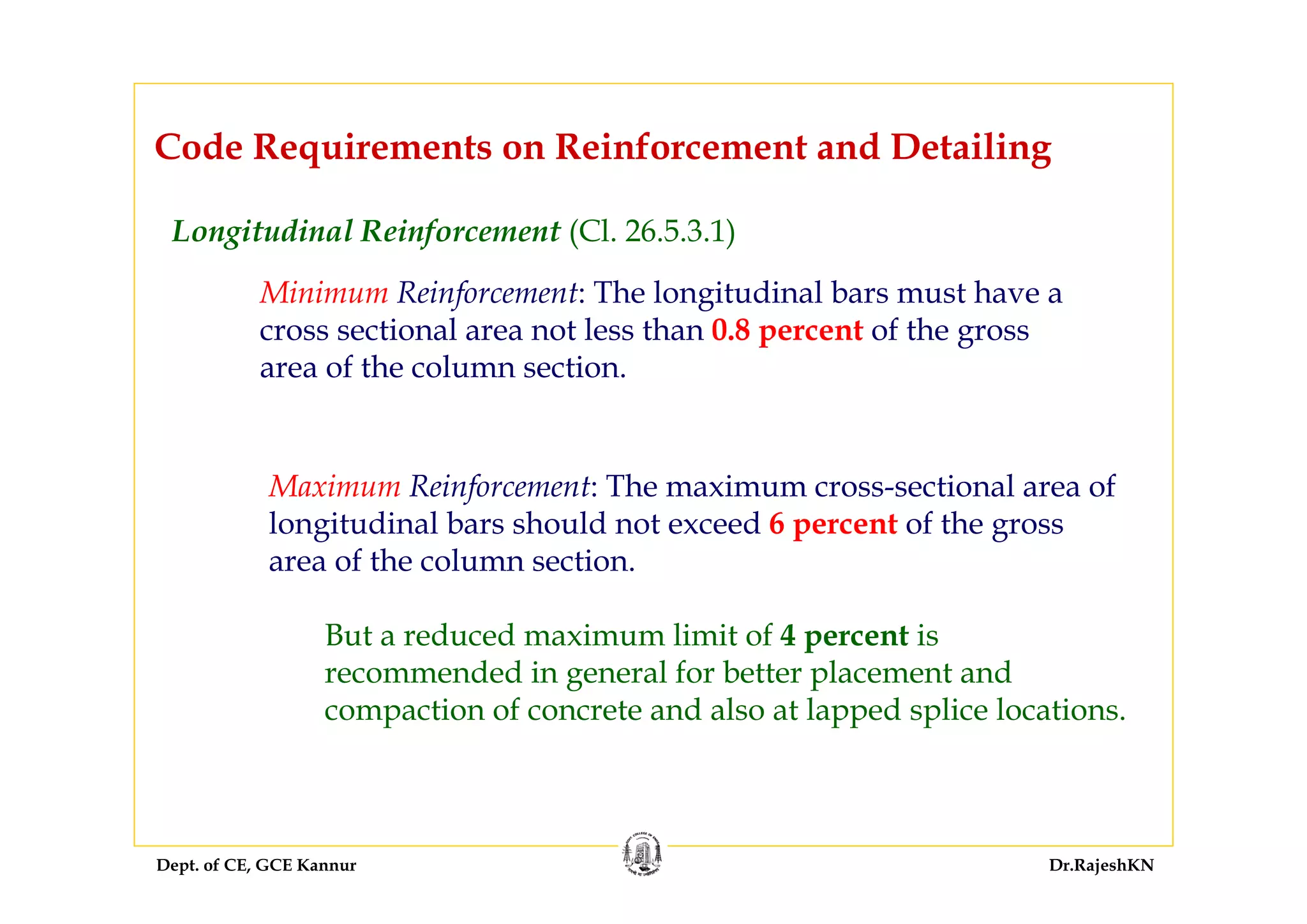

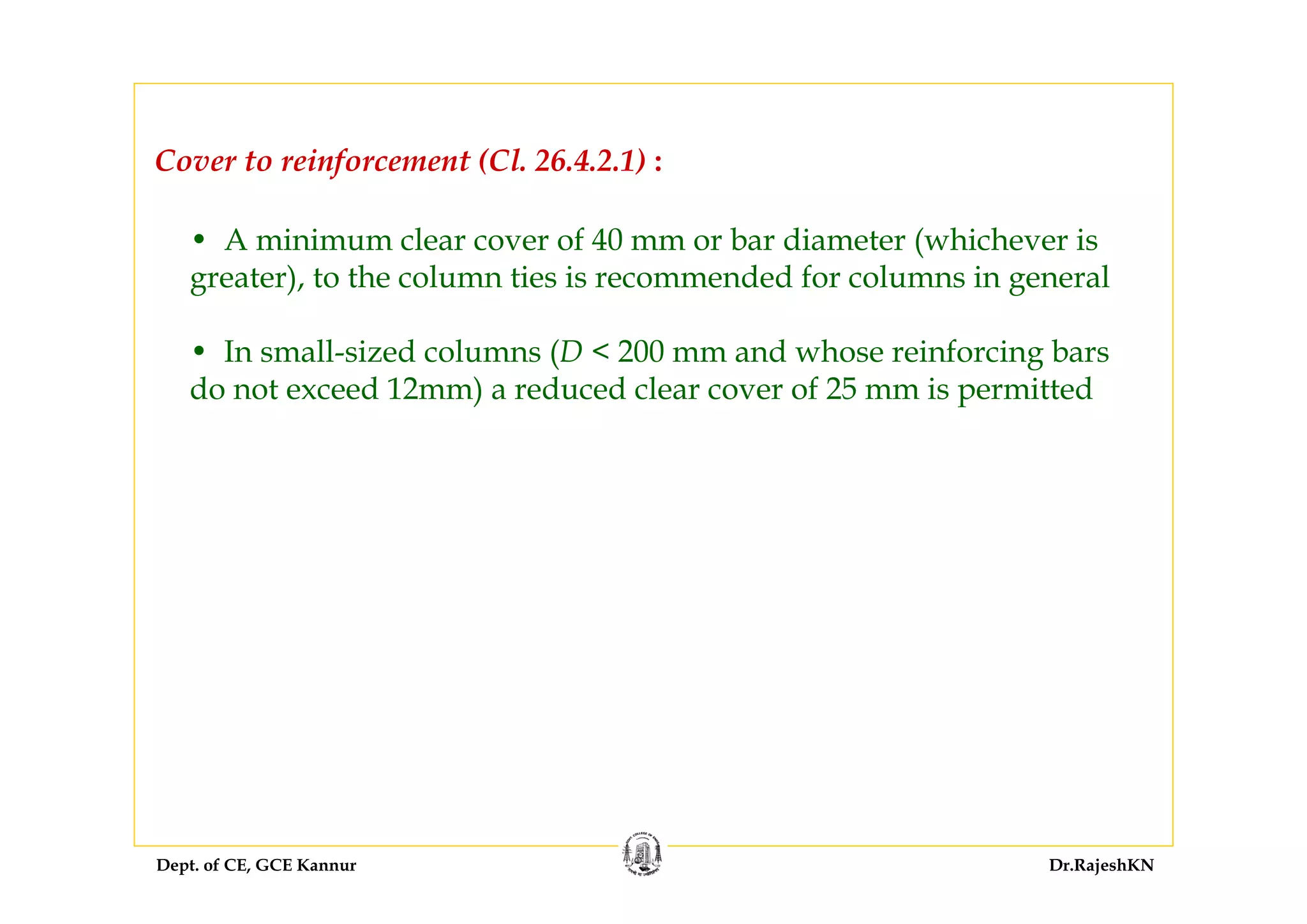

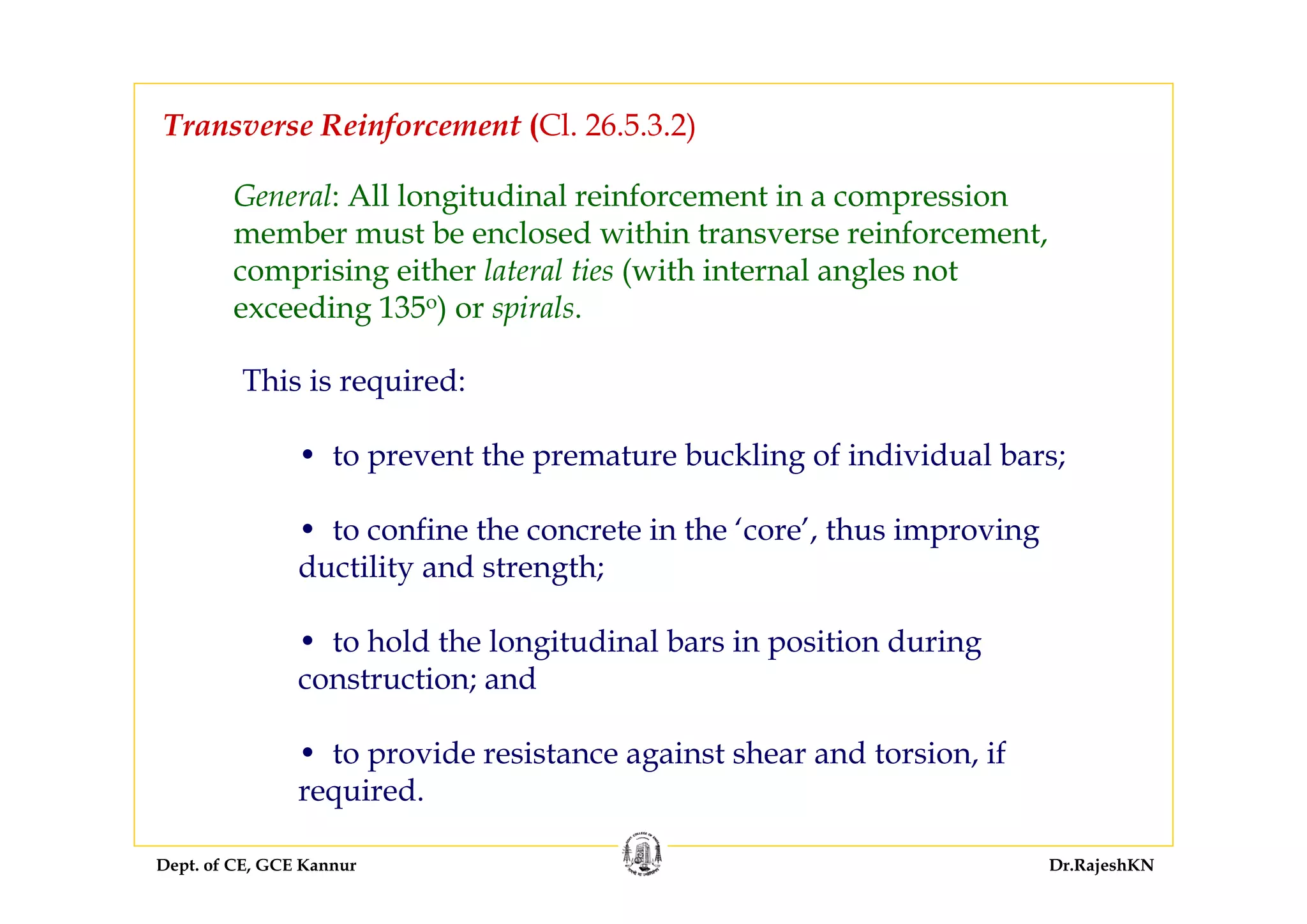

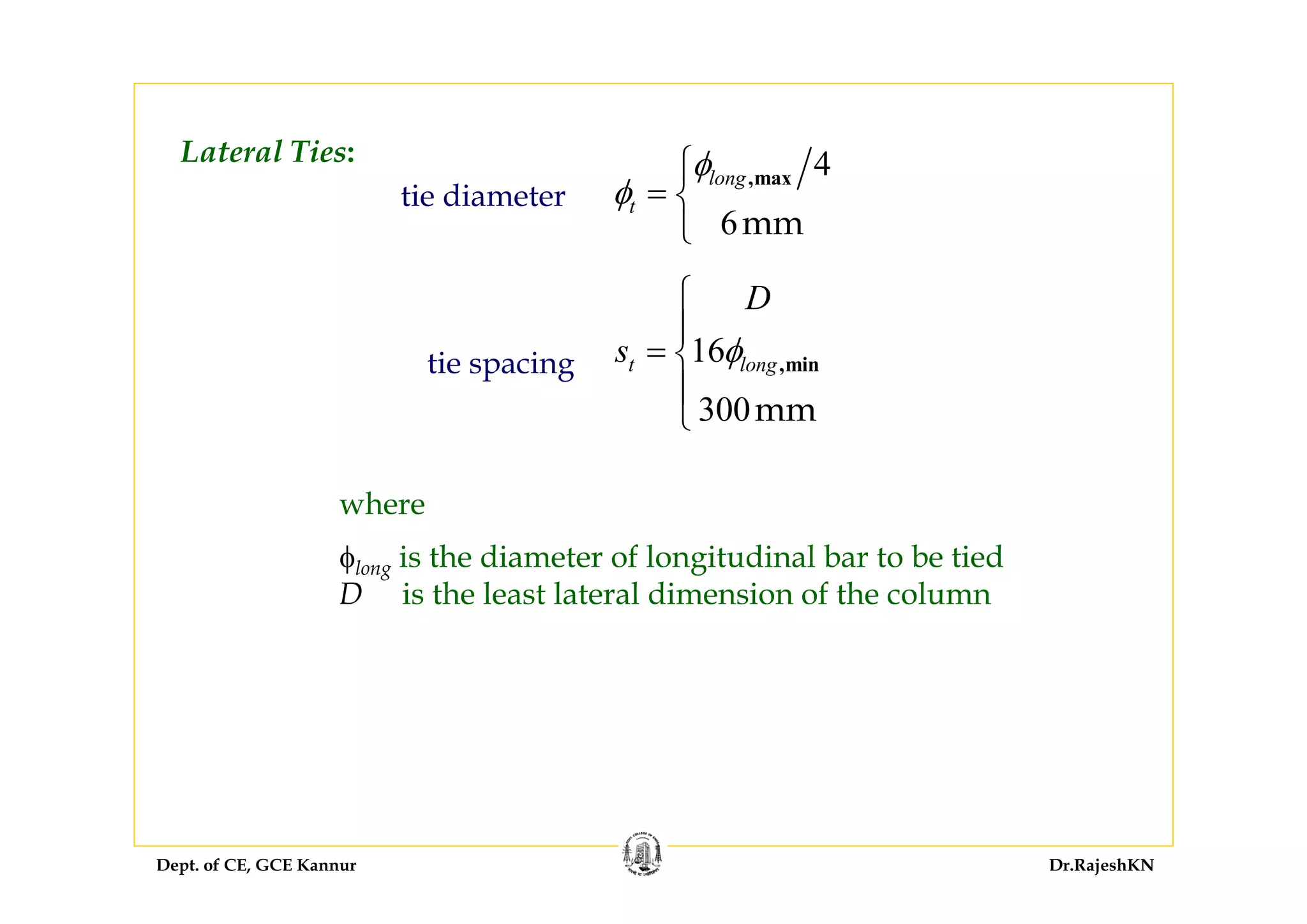

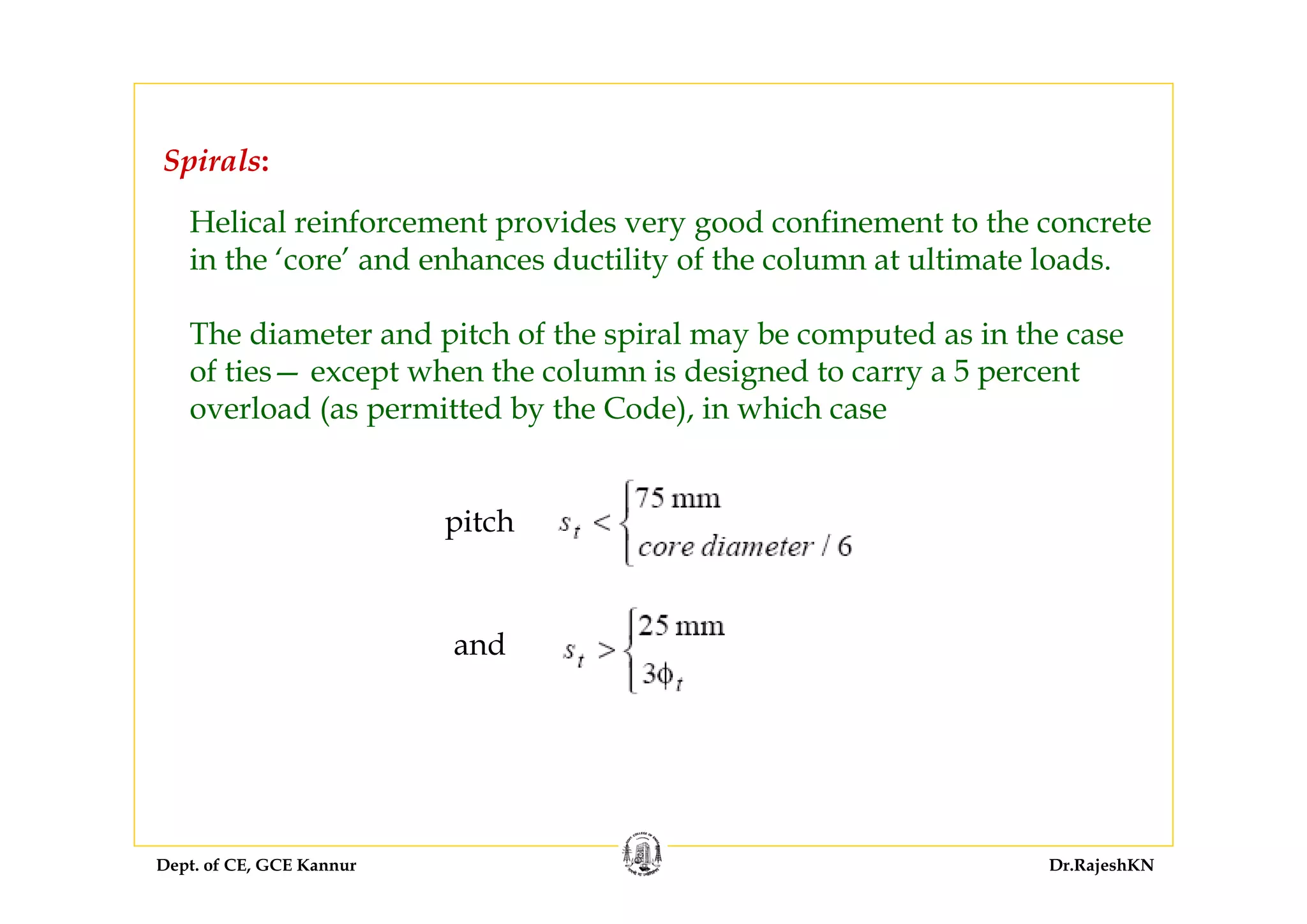

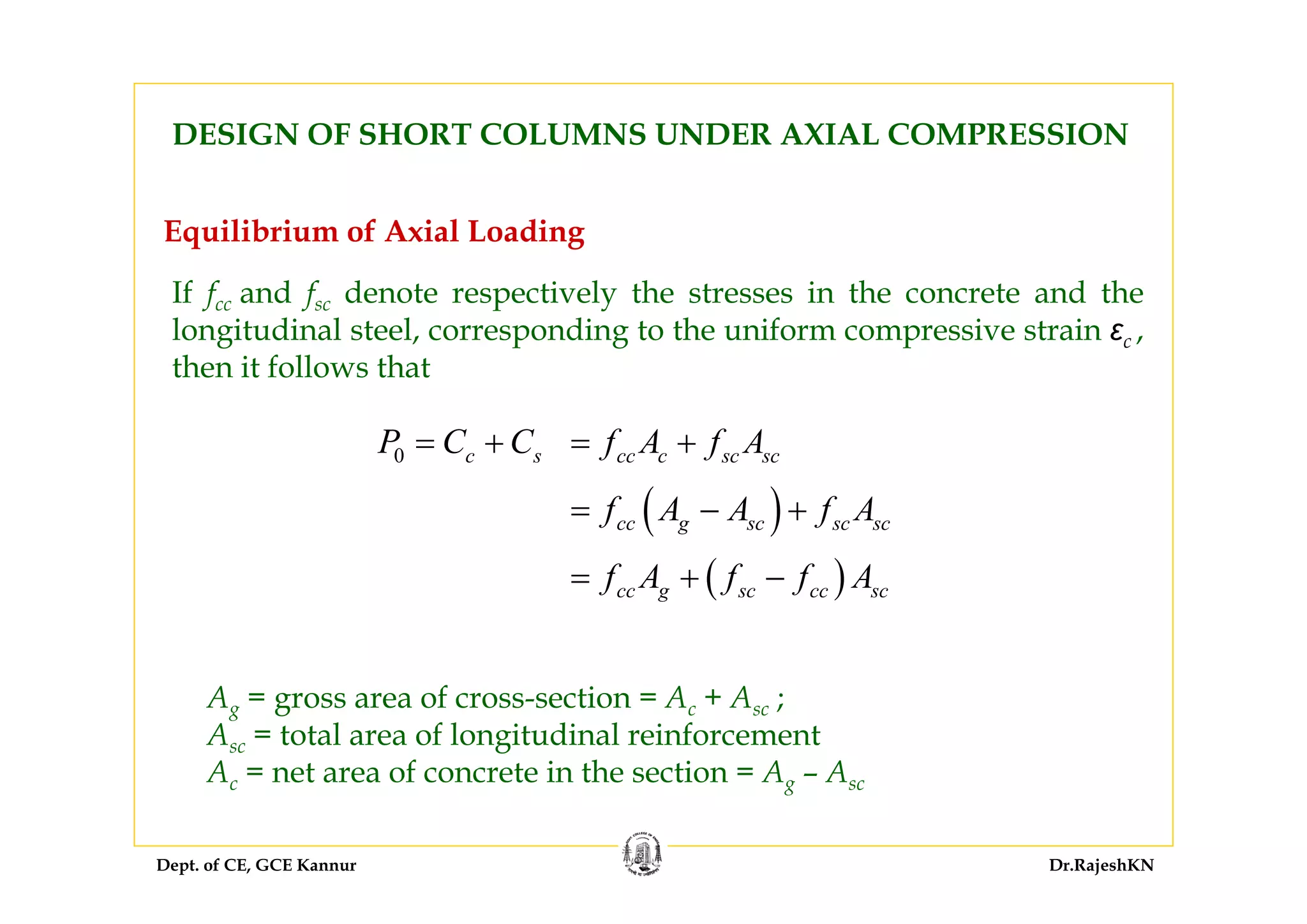

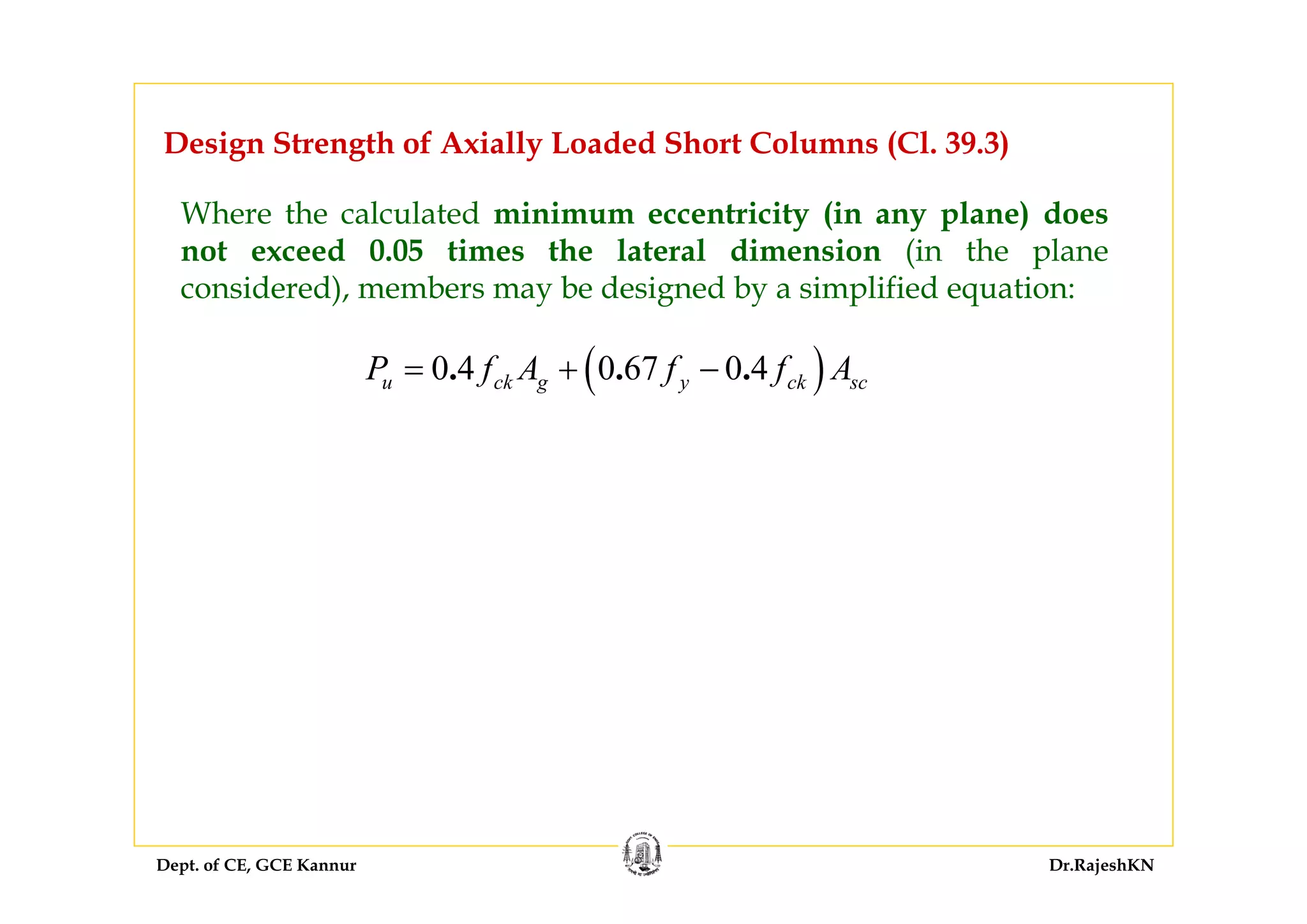

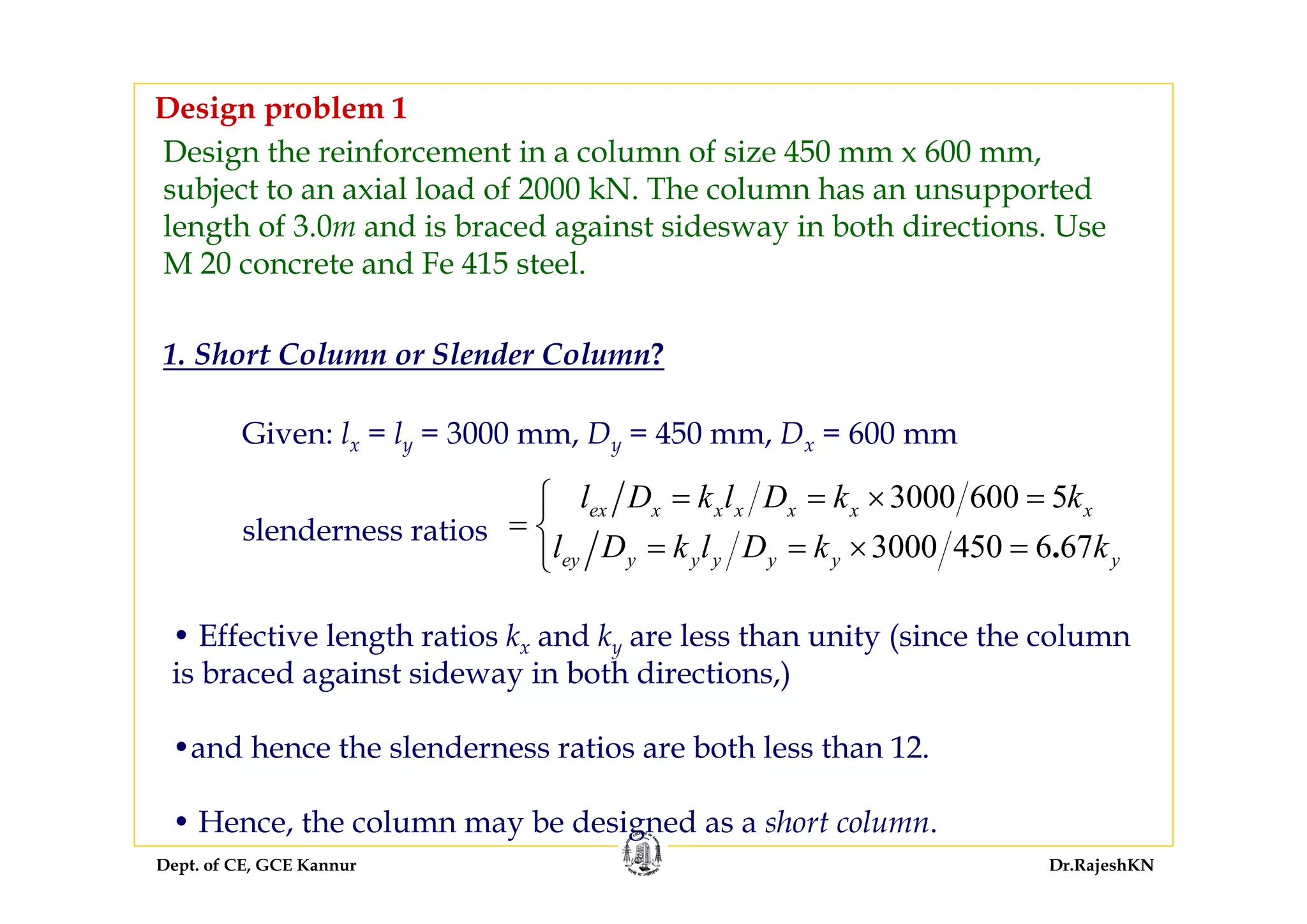

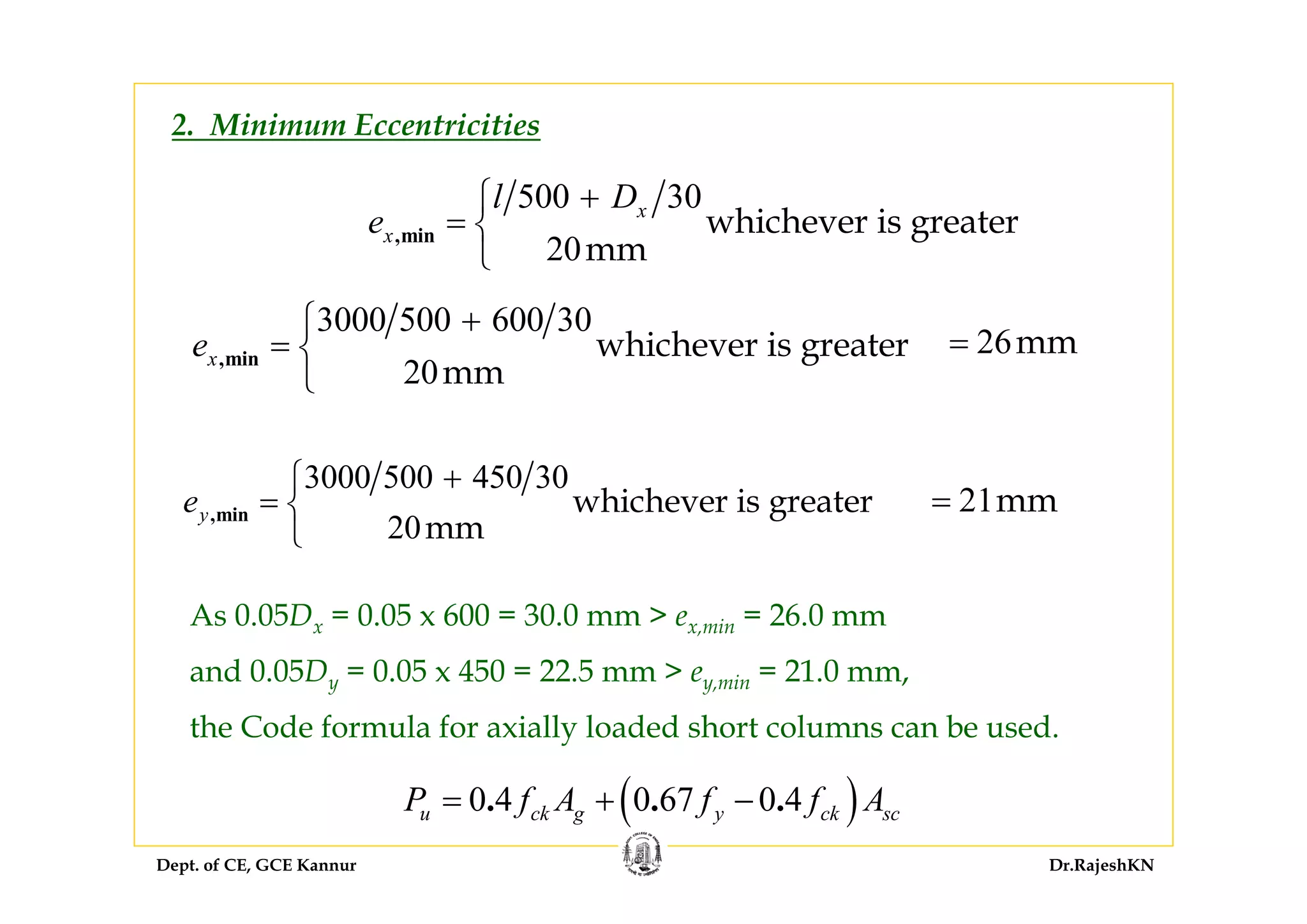

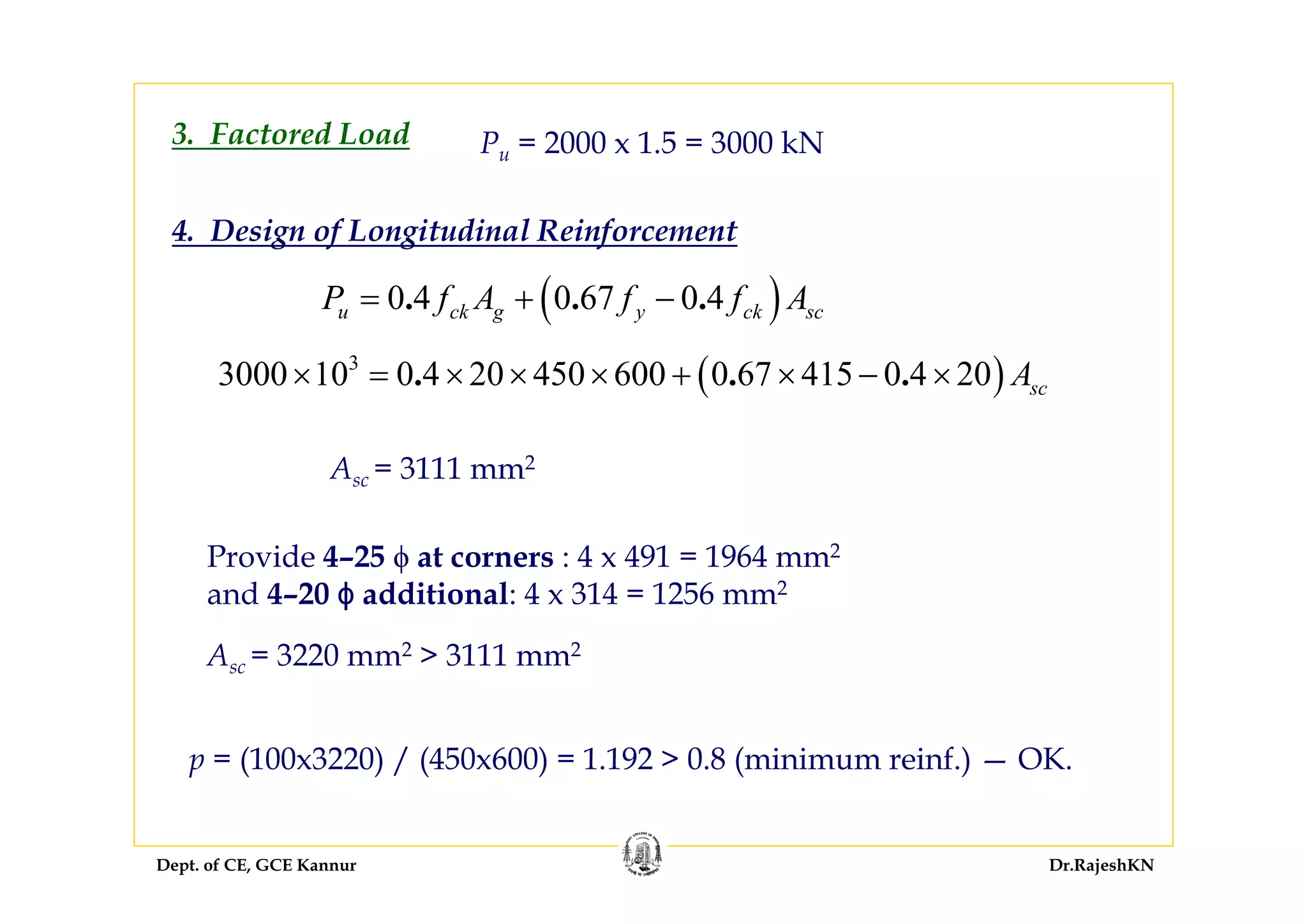

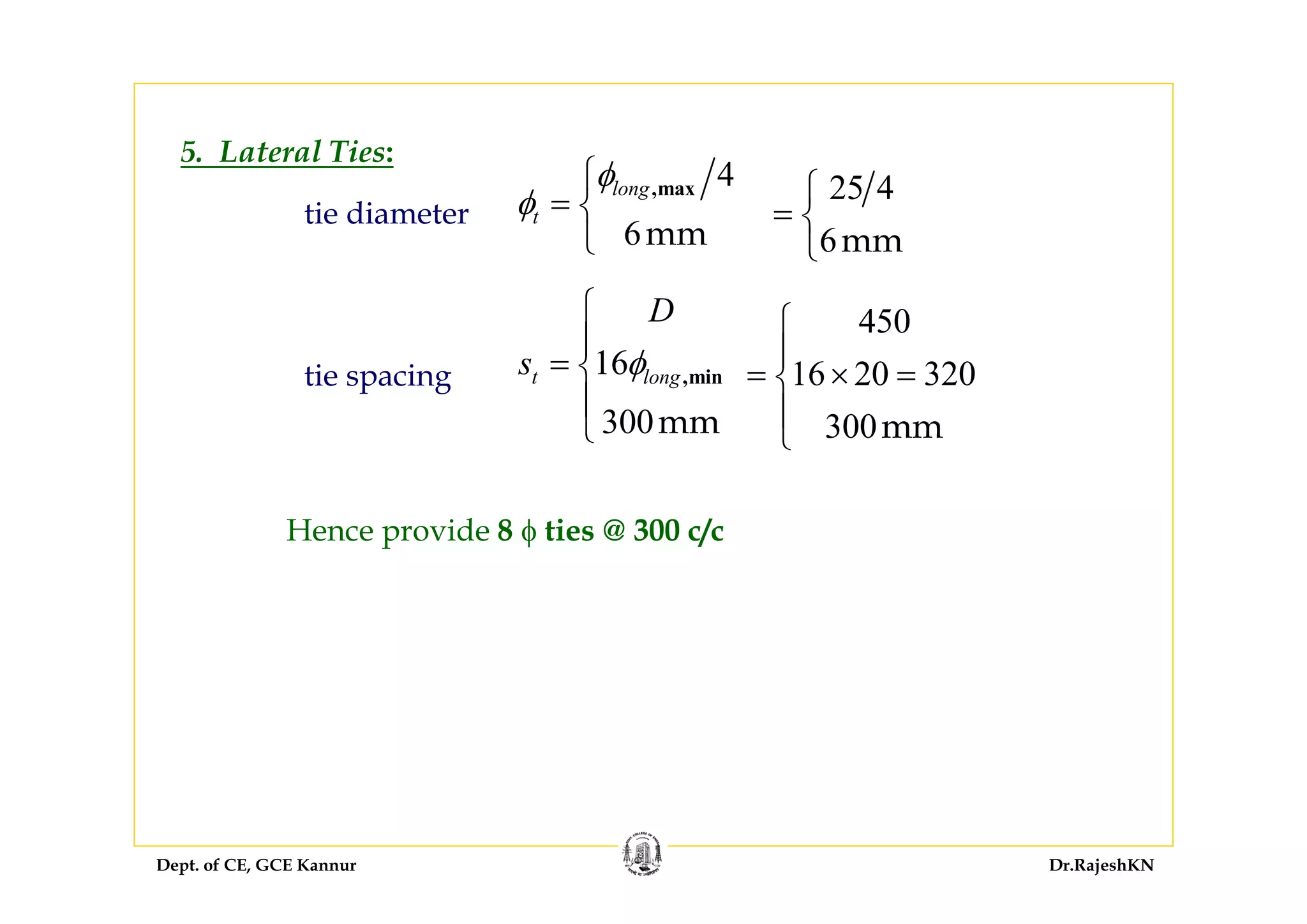

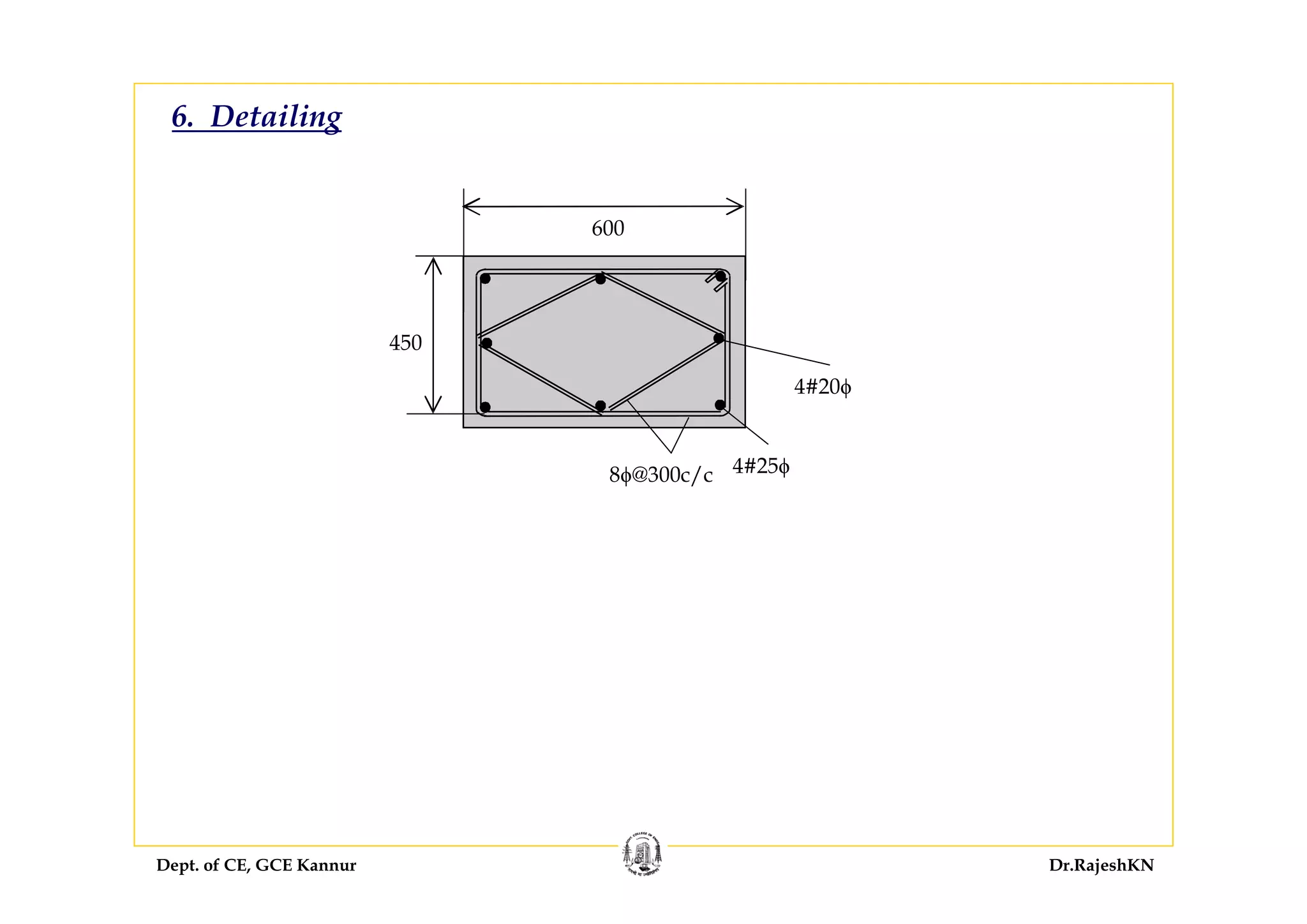

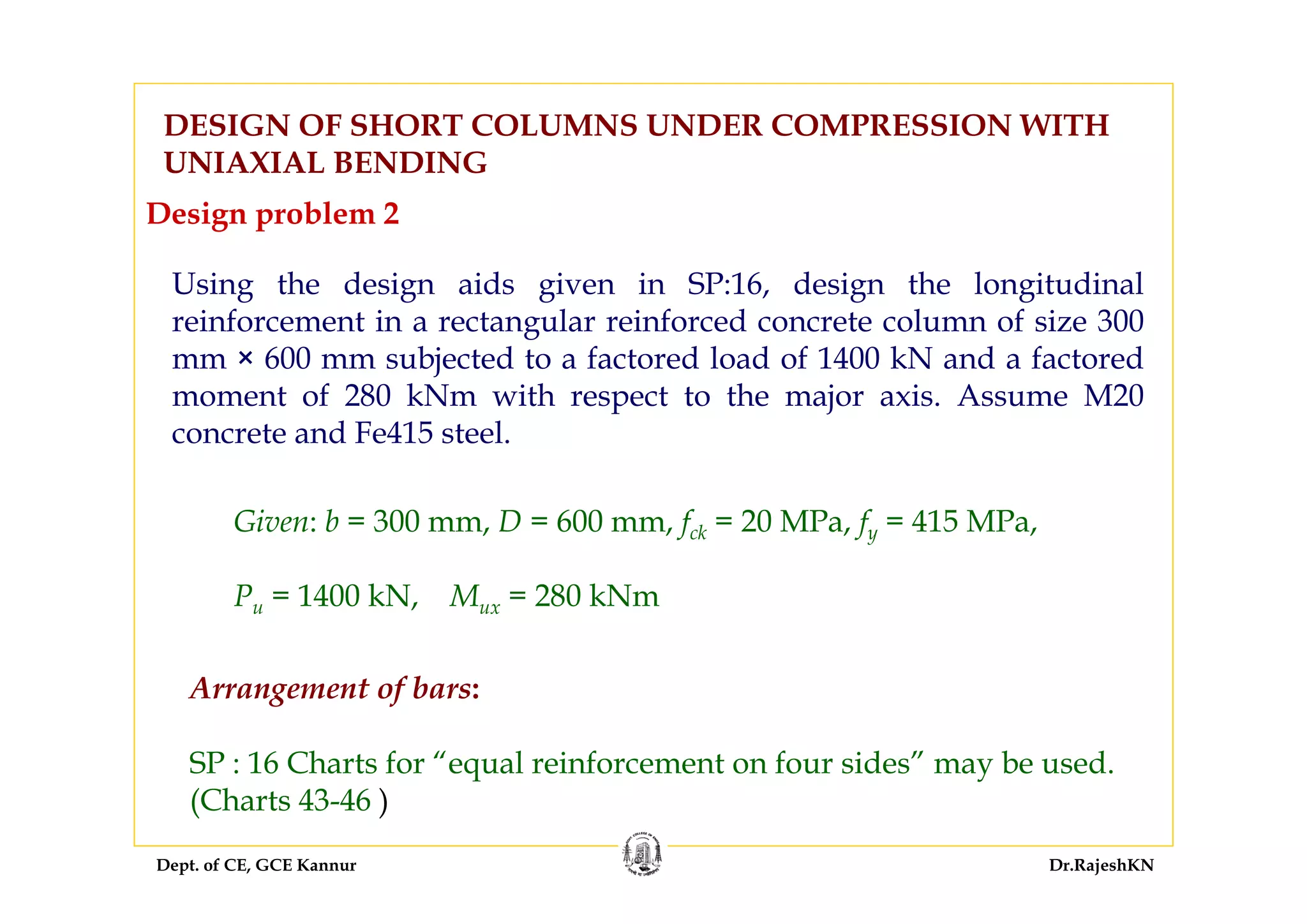

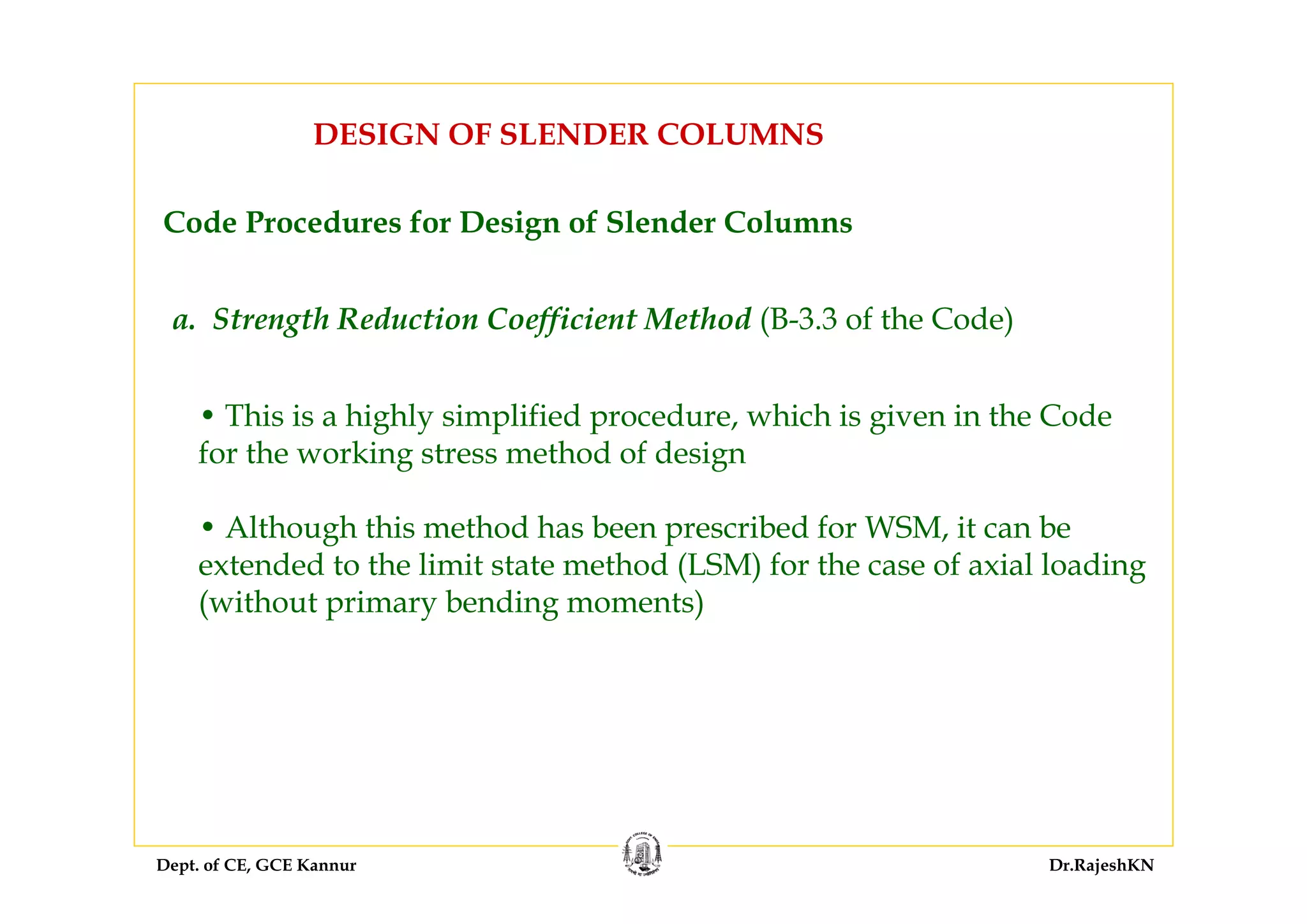

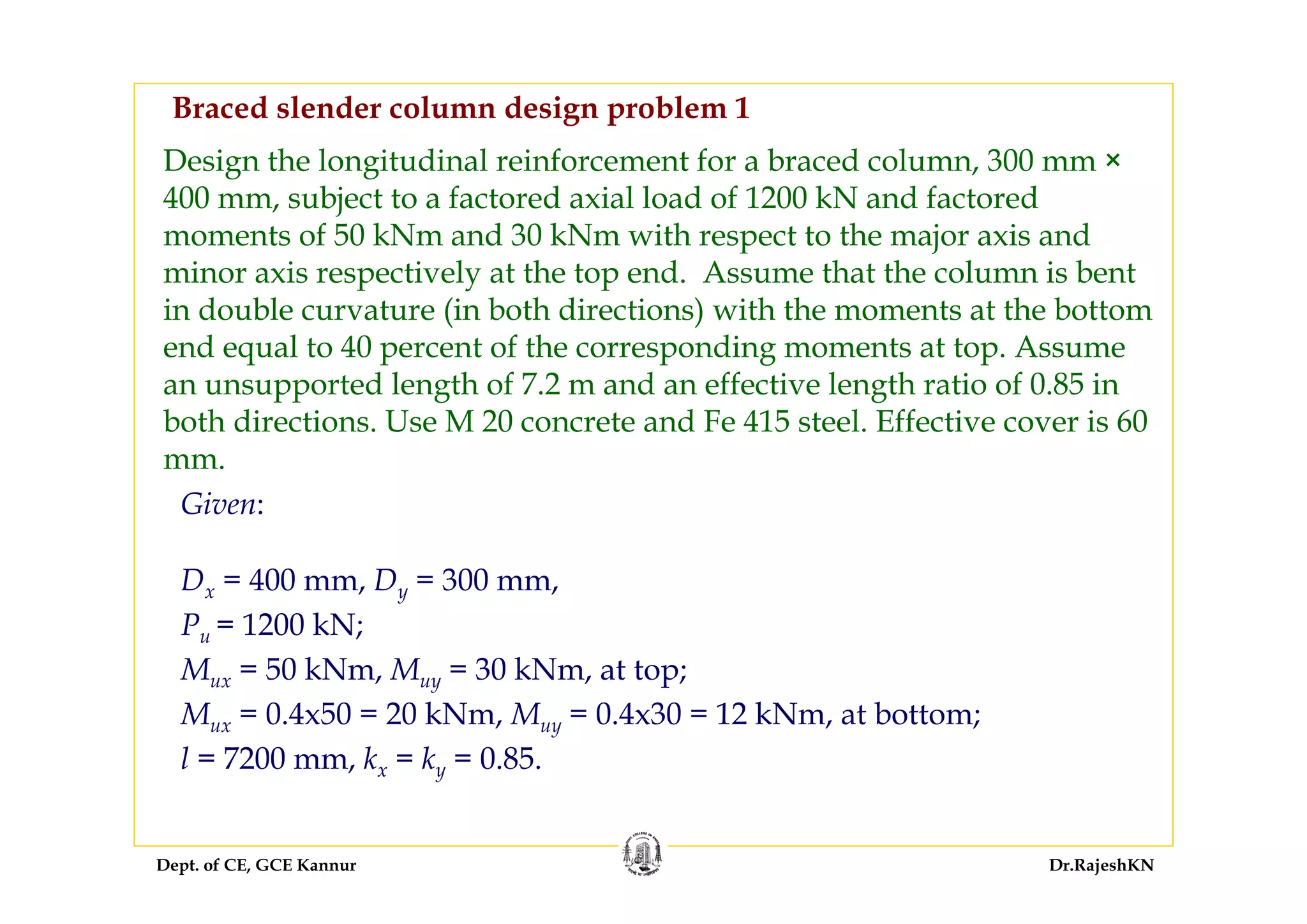

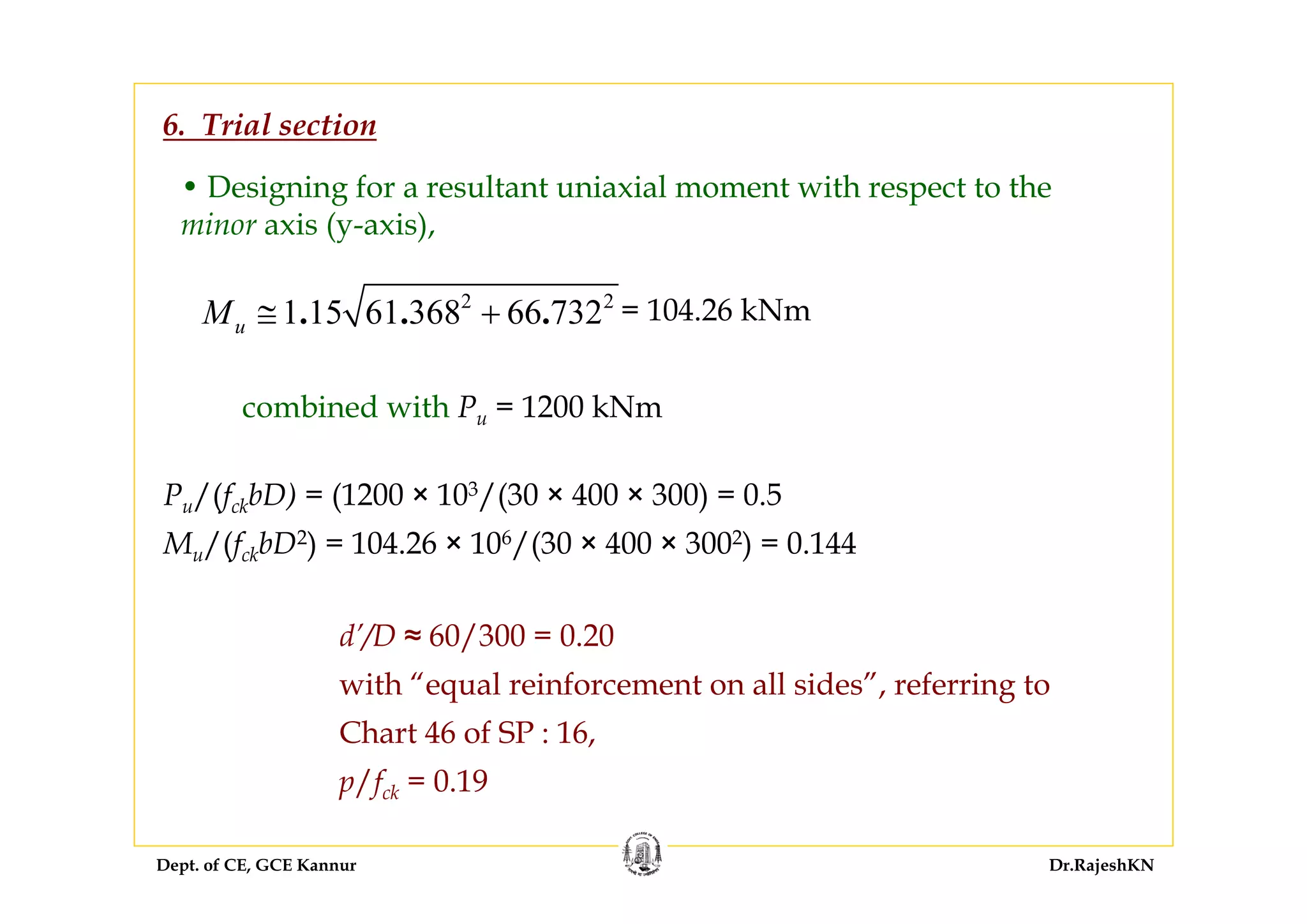

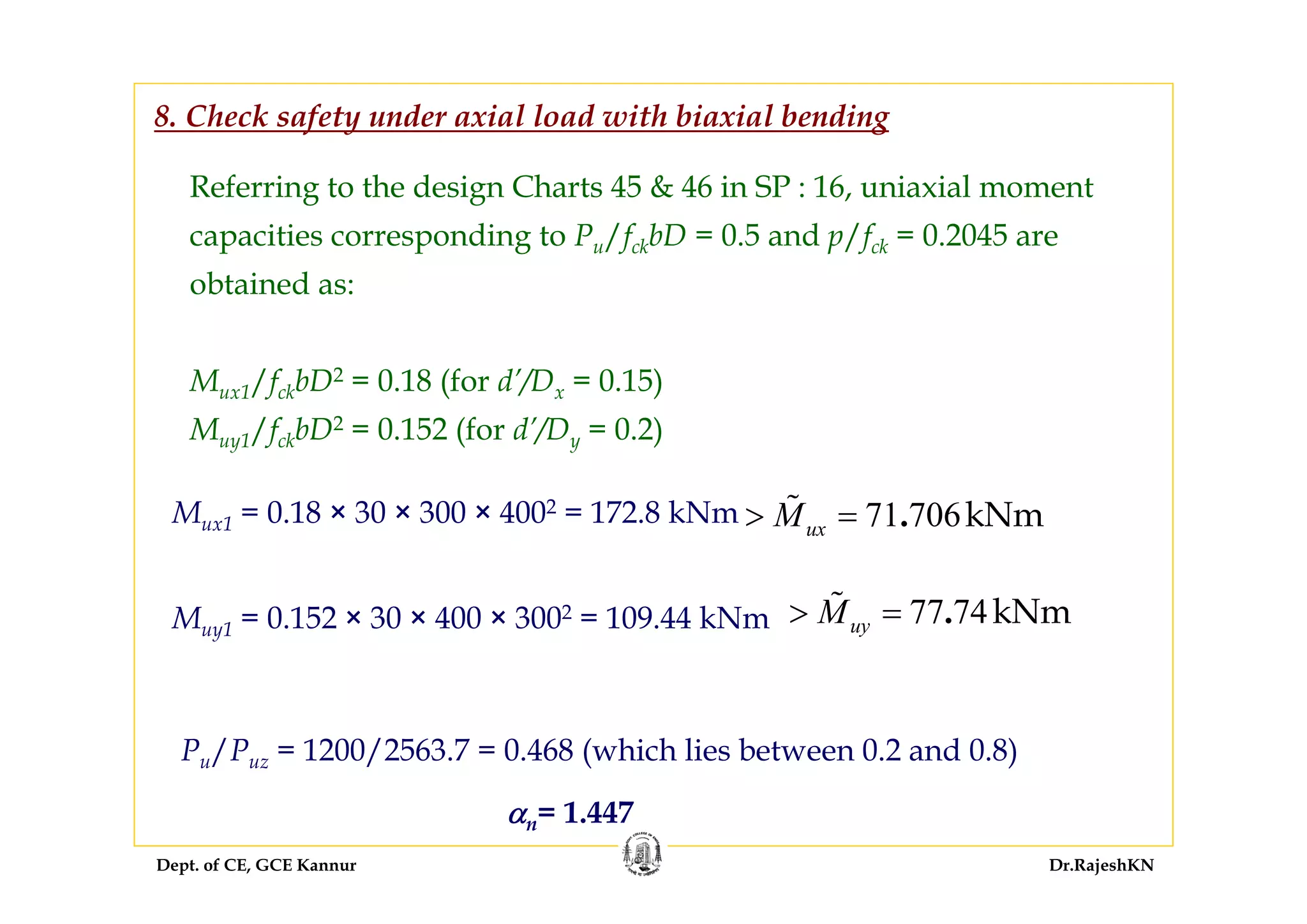

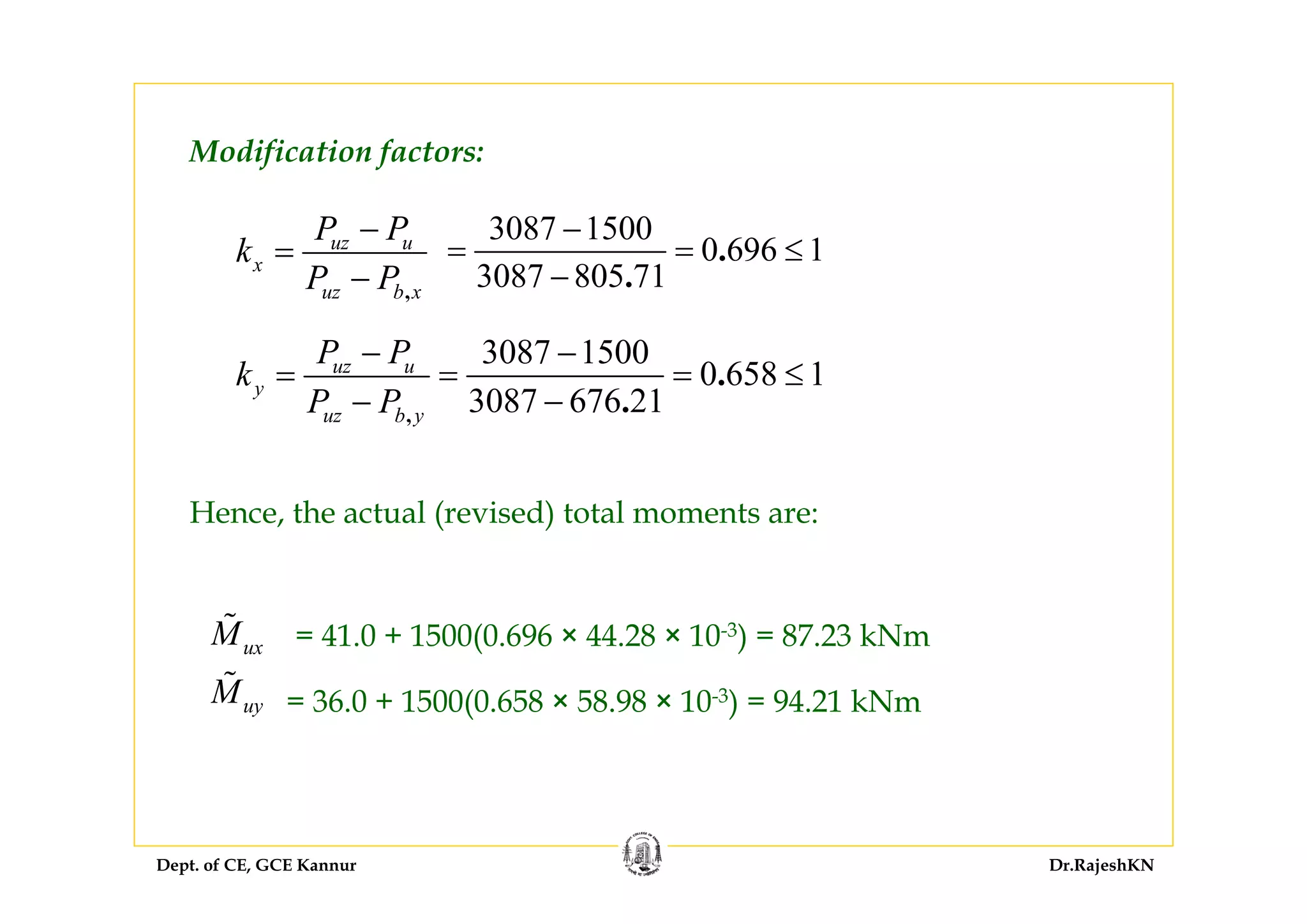

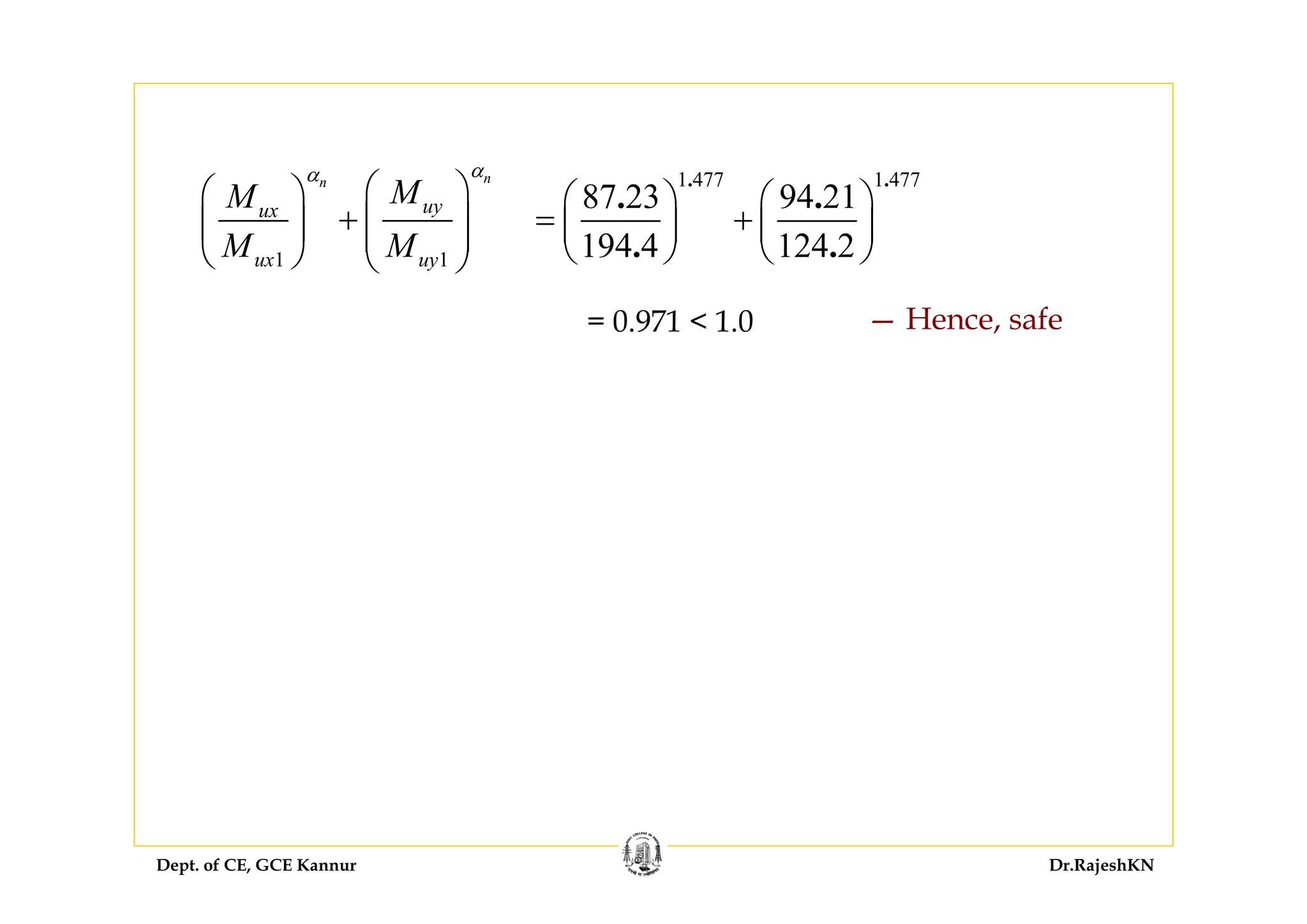

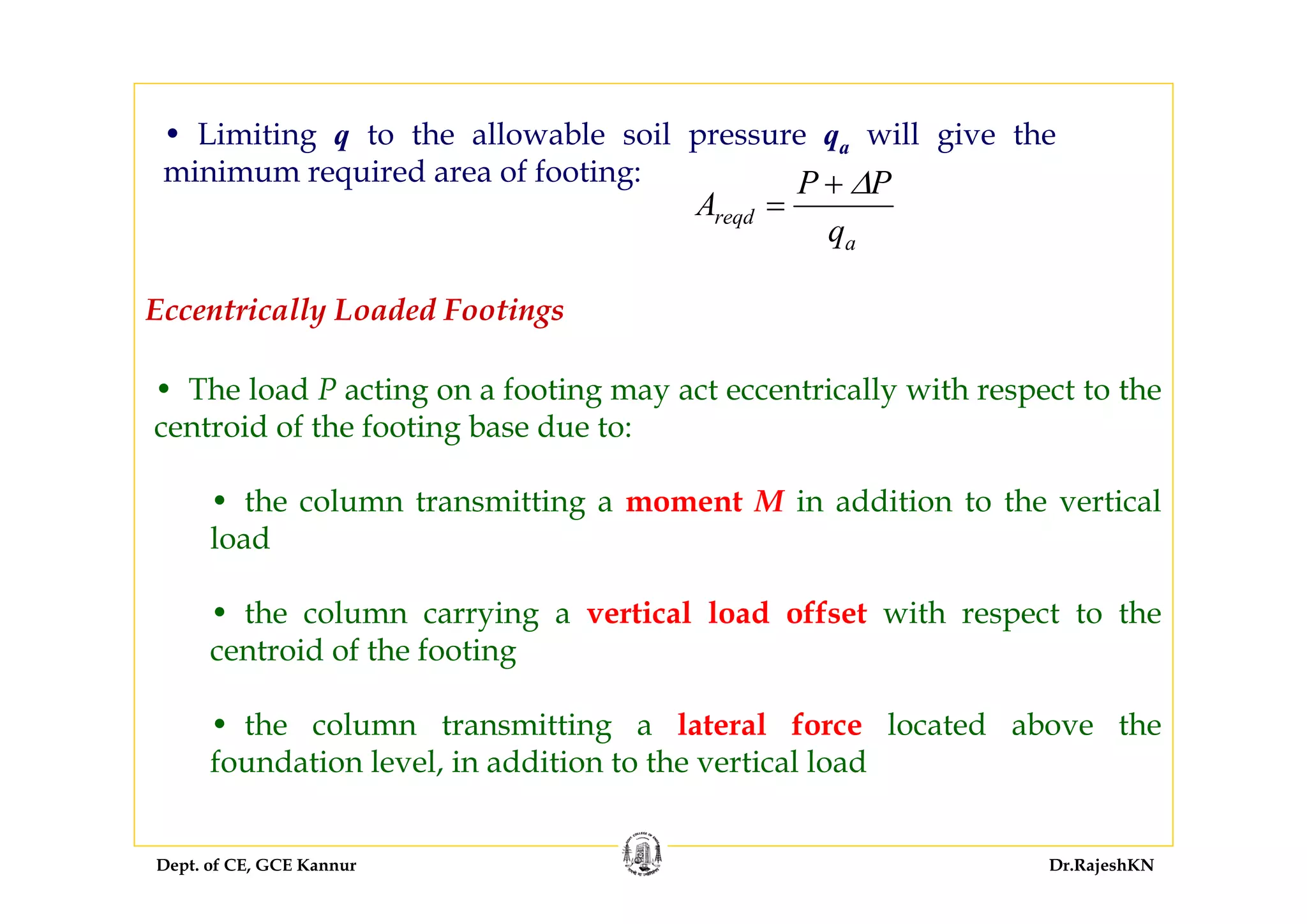

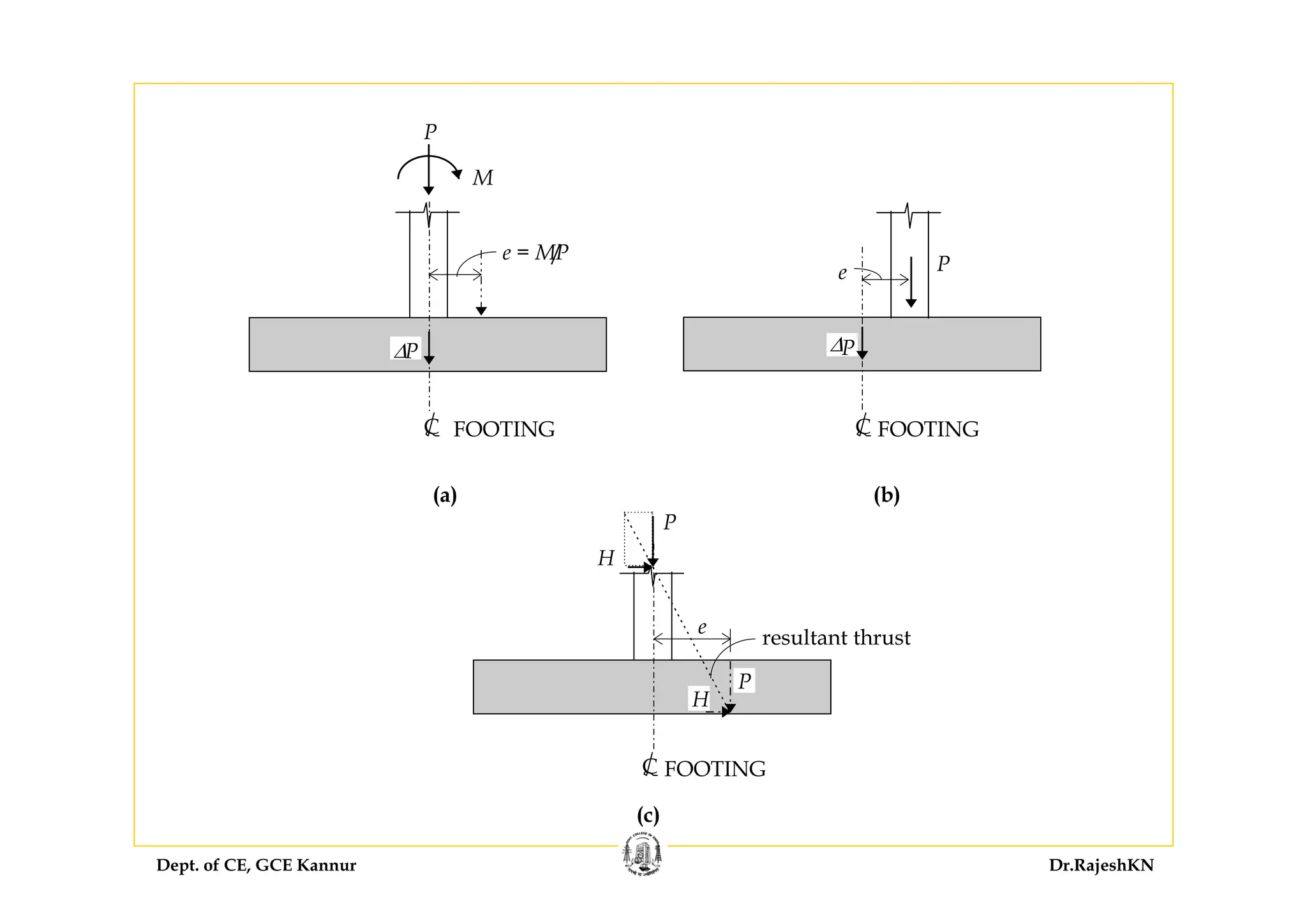

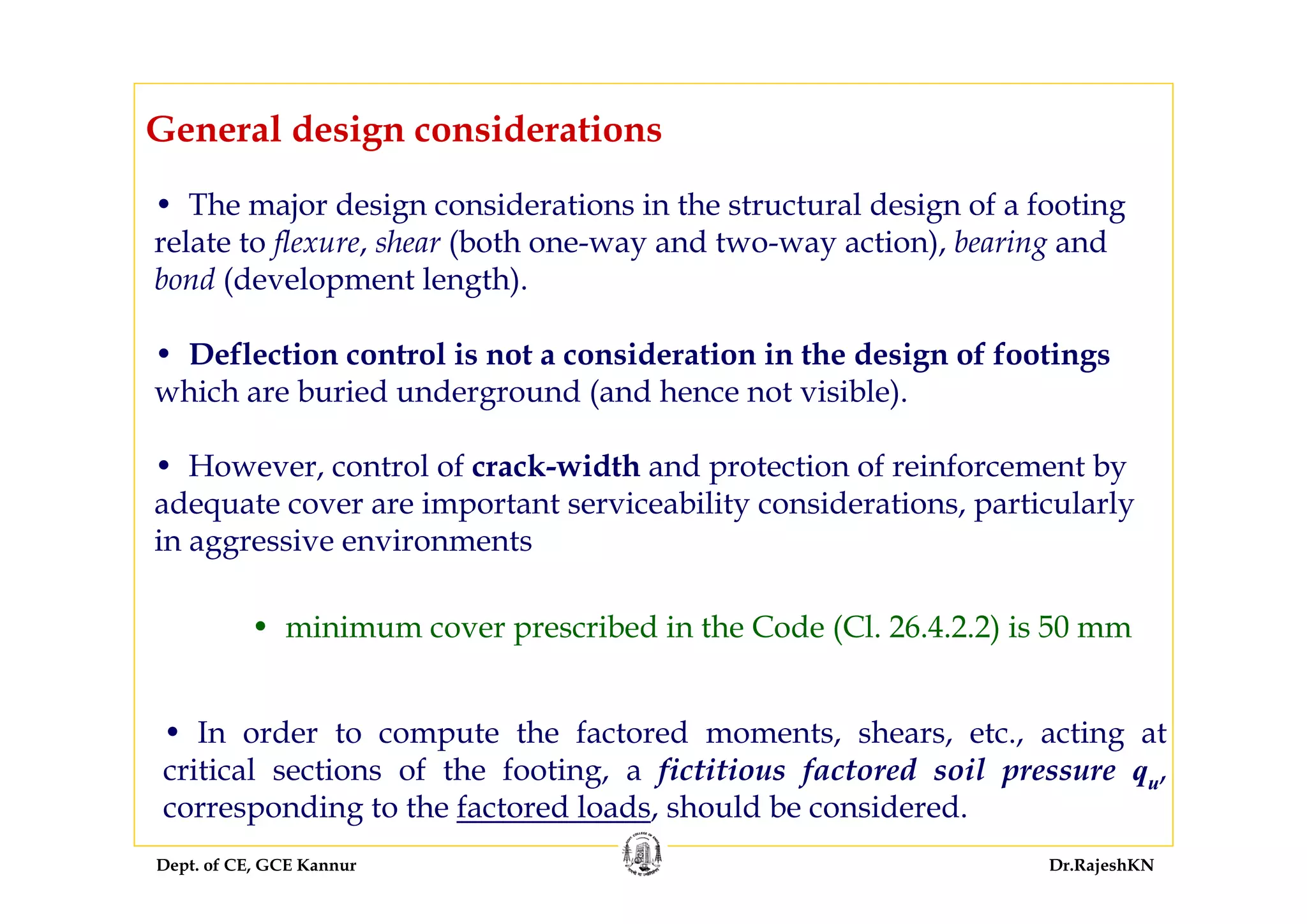

The document discusses the design of columns and footings in concrete structures. It covers various topics related to column design including classification of columns based on type of reinforcement, loading, and slenderness ratios. Short columns subjected to axial loads with or without eccentricity are analyzed. Design aspects such as effective length, minimum reinforcement requirements, cover and transverse tie spacing are described based on code specifications. Equations for equilibrium of uniformly loaded short columns are also presented.

![Dept. of CE, GCE Kannur Dr.RajeshKN

Columns

• A ‘compression member’ is a structural element which is subjected

(predominantly) to axial compressive forces.

• Compression members are most commonly encountered in

reinforced concrete buildings as columns

• Column is a compression member, the ‘effective length’ of which

exceeds three times the least lateral dimension (Cl. 25.1.1)

• ‘Pedestal’ is a vertical compression member whose ‘effective length’

is less than three times its least lateral dimension [Cl. 26.5.3.1(h)].](https://image.slidesharecdn.com/sd-i-module4-rajeshsir-140806050206-phpapp02/75/Sd-i-module4-rajesh-sir-4-2048.jpg)

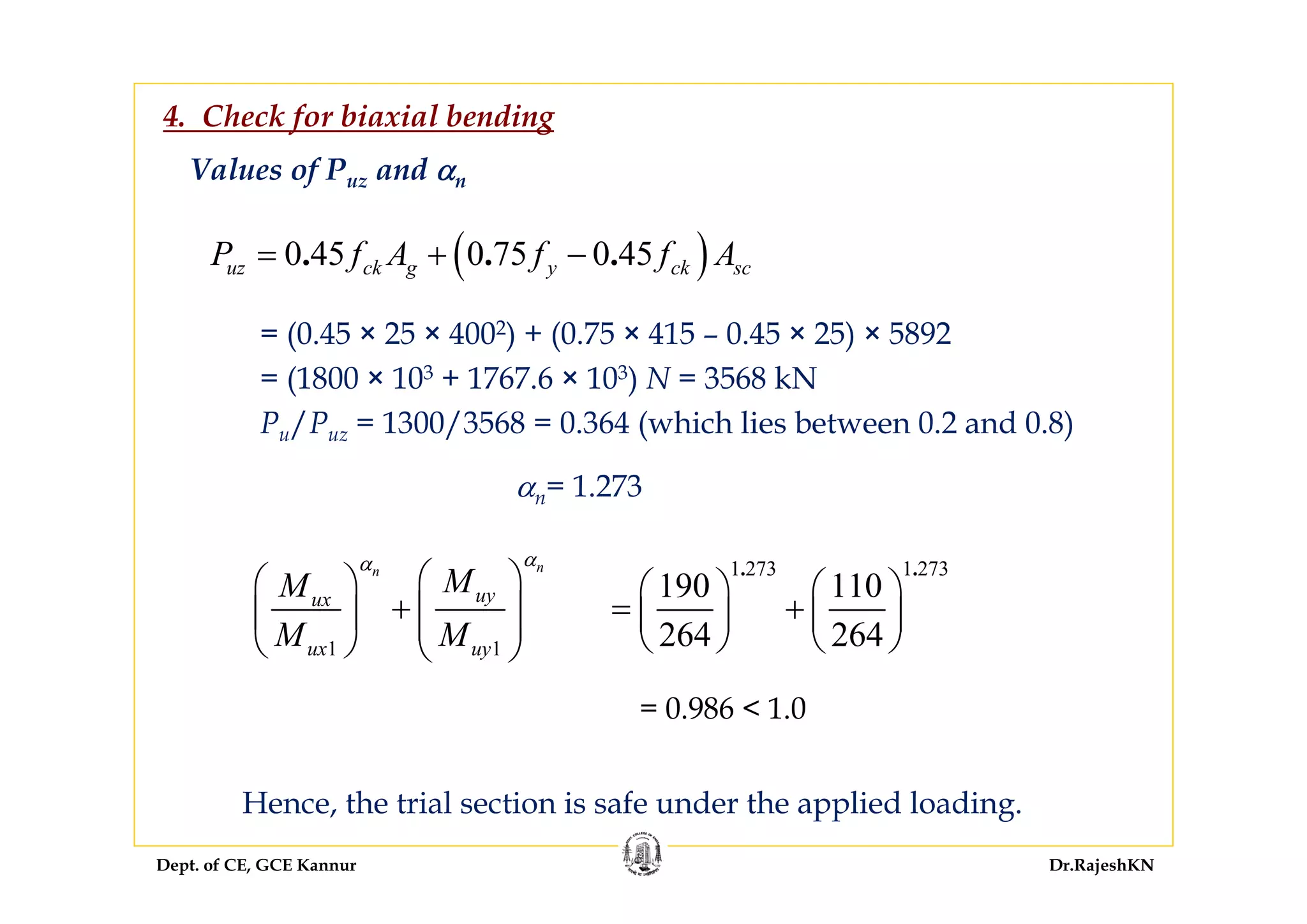

![Dept. of CE, GCE Kannur Dr.RajeshKN

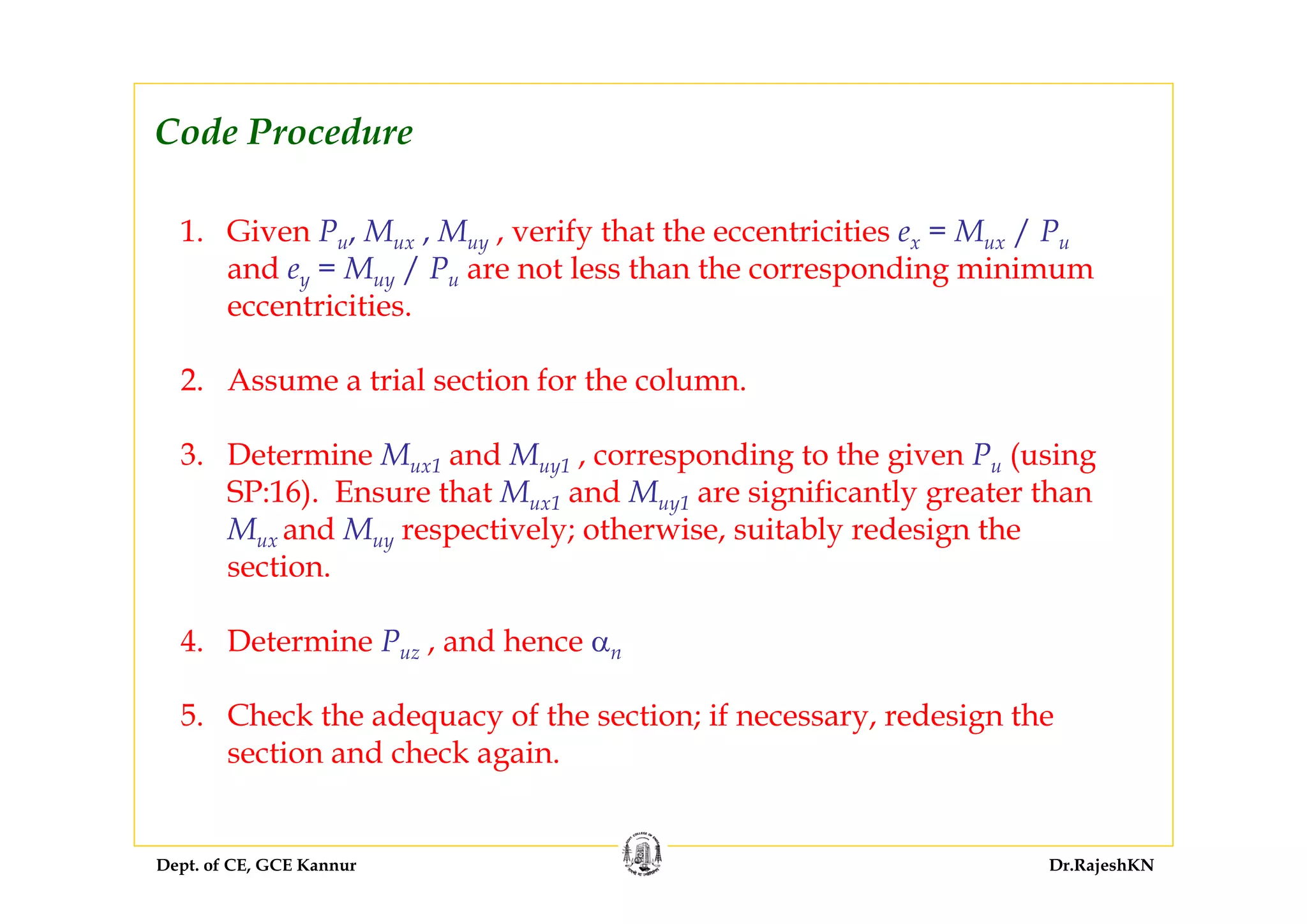

Assume longitudinal reinforcement percentage as 3.5%.

Designing for uniaxial eccentricity with Pu = 1300 kN and

3. Trial section: Longitudinal reinforcement

As,reqd = 3.5 × 4002/100 = 5600 mm2

Provide 12 – 25 dia: As = 491 × 12 = 5892 mm2 > 5600 mm2. The

arrangement of bars is shown in Figure??.

Uniaxial moment capacities: Mux1, Muy1 [Here, due to symmetry, Mux1

= Mux2]

= 0.325

u

ck

P

f bd](https://image.slidesharecdn.com/sd-i-module4-rajeshsir-140806050206-phpapp02/75/Sd-i-module4-rajesh-sir-40-2048.jpg)

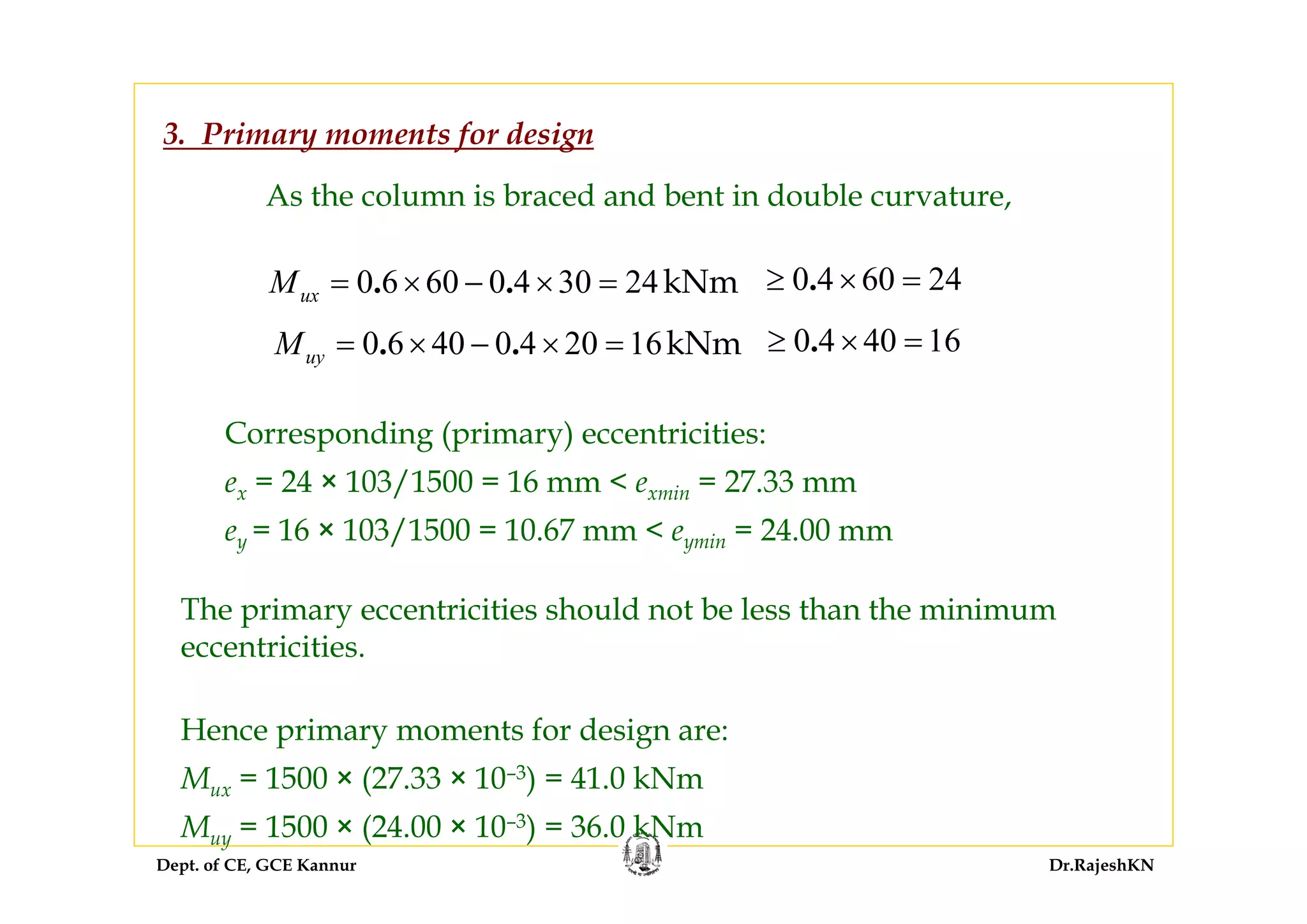

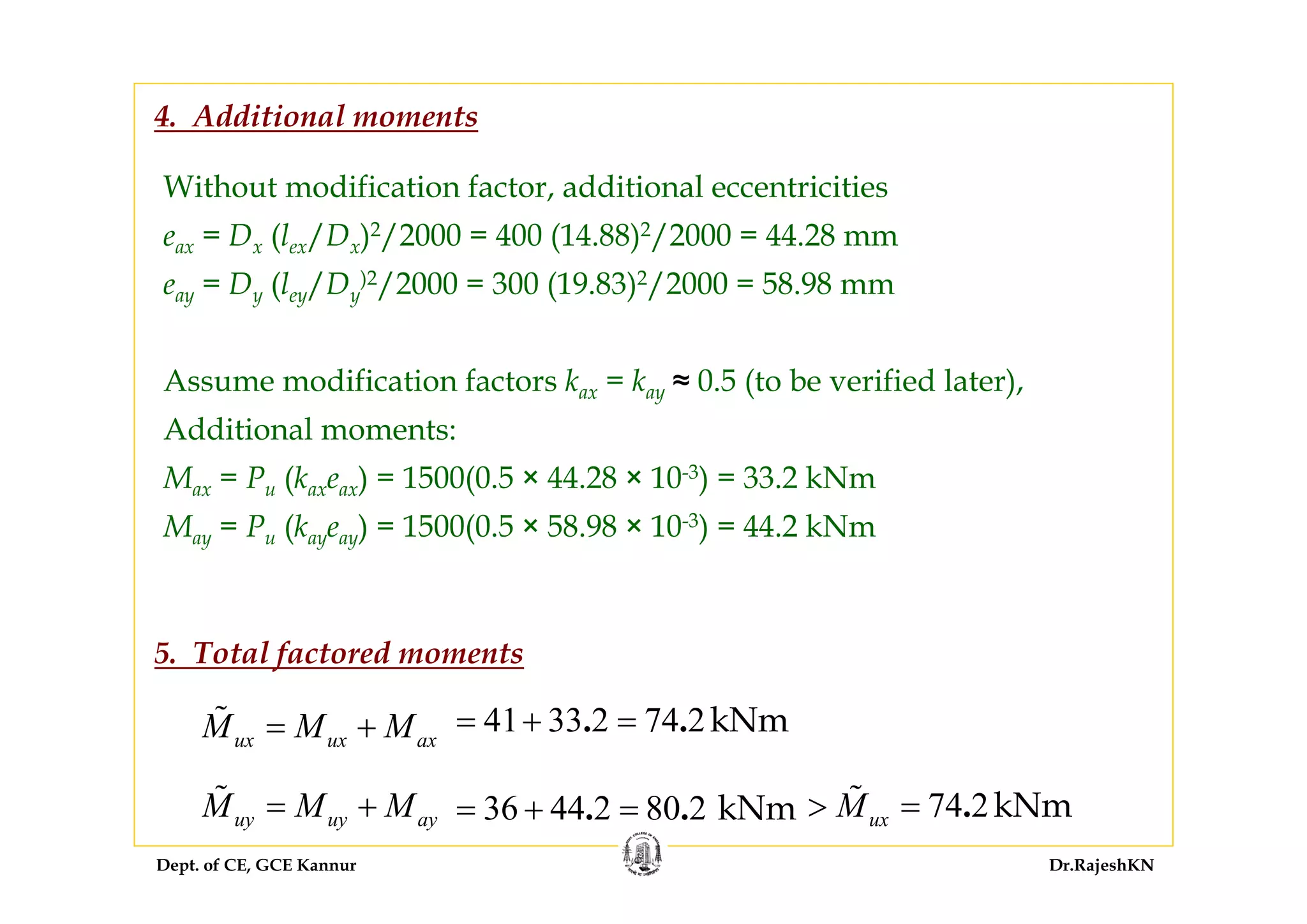

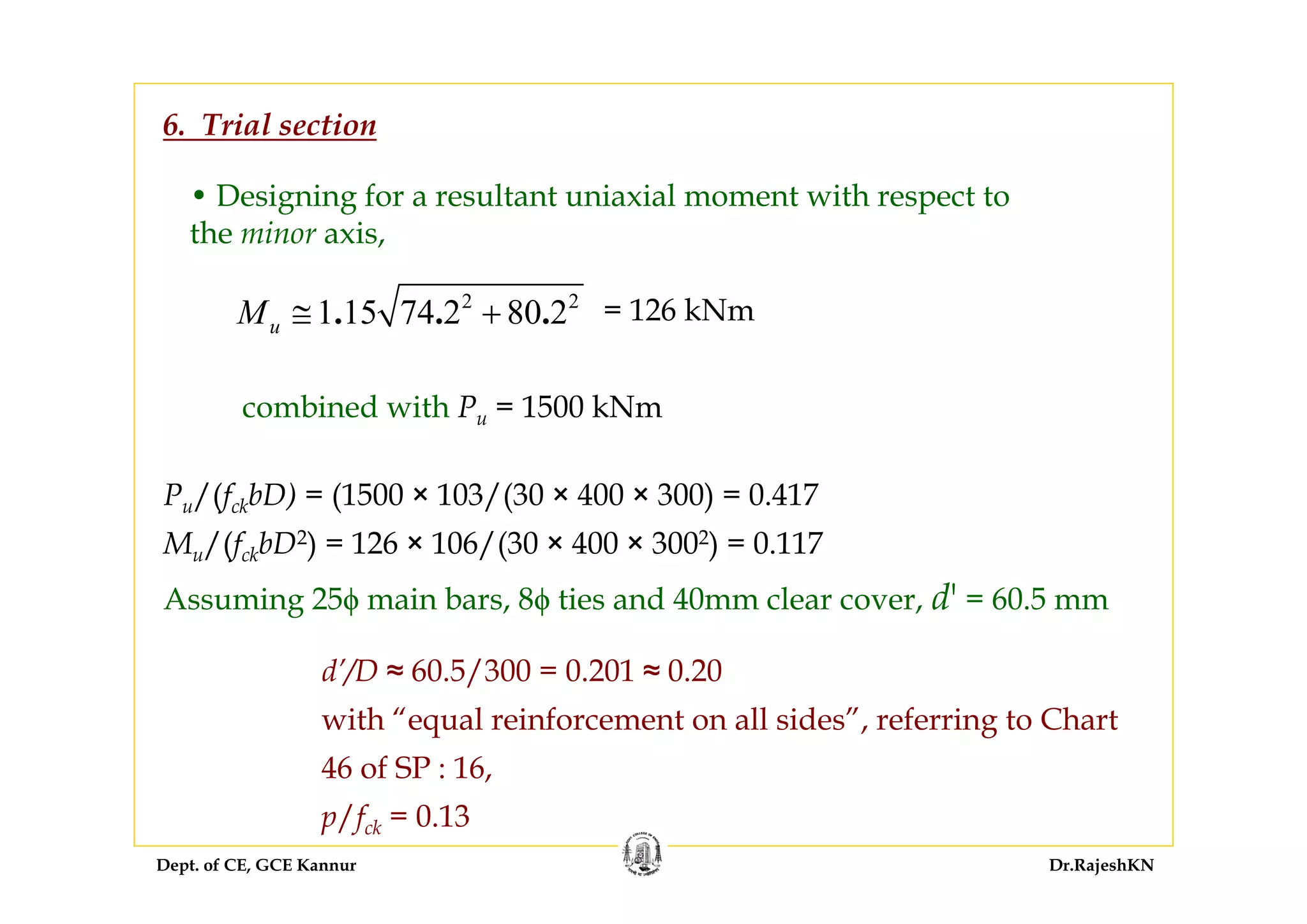

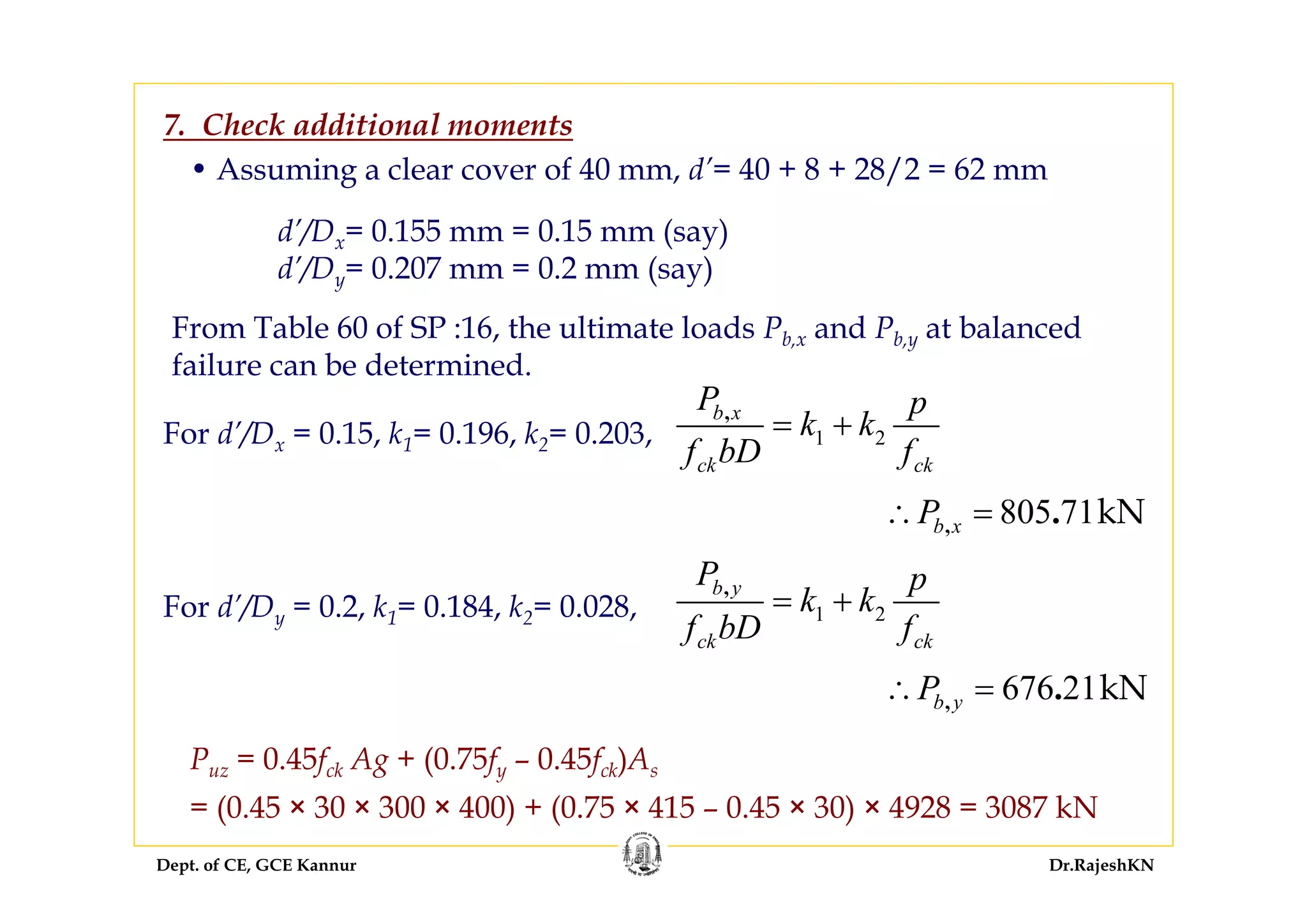

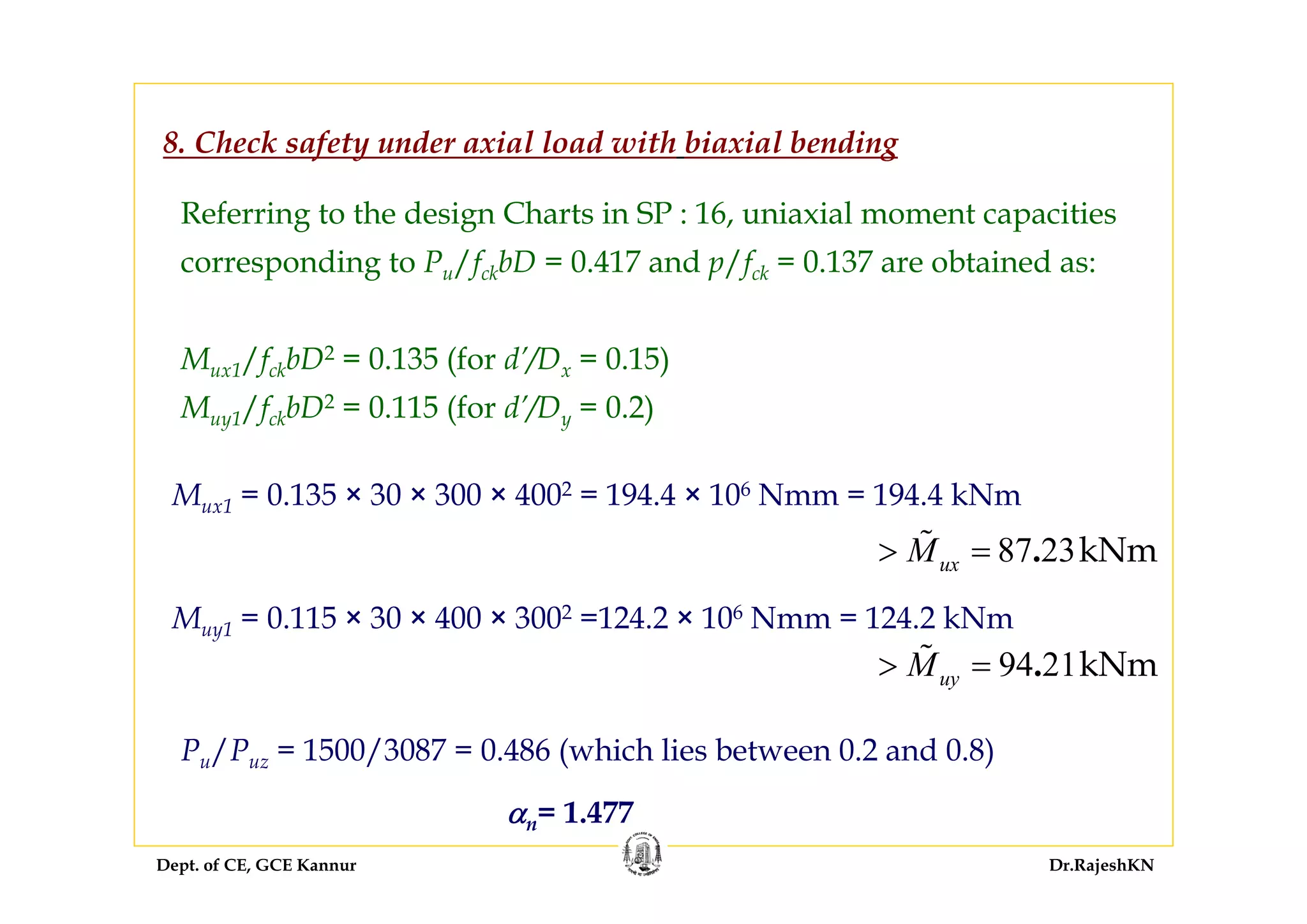

![Dept. of CE, GCE Kannur Dr.RajeshKN

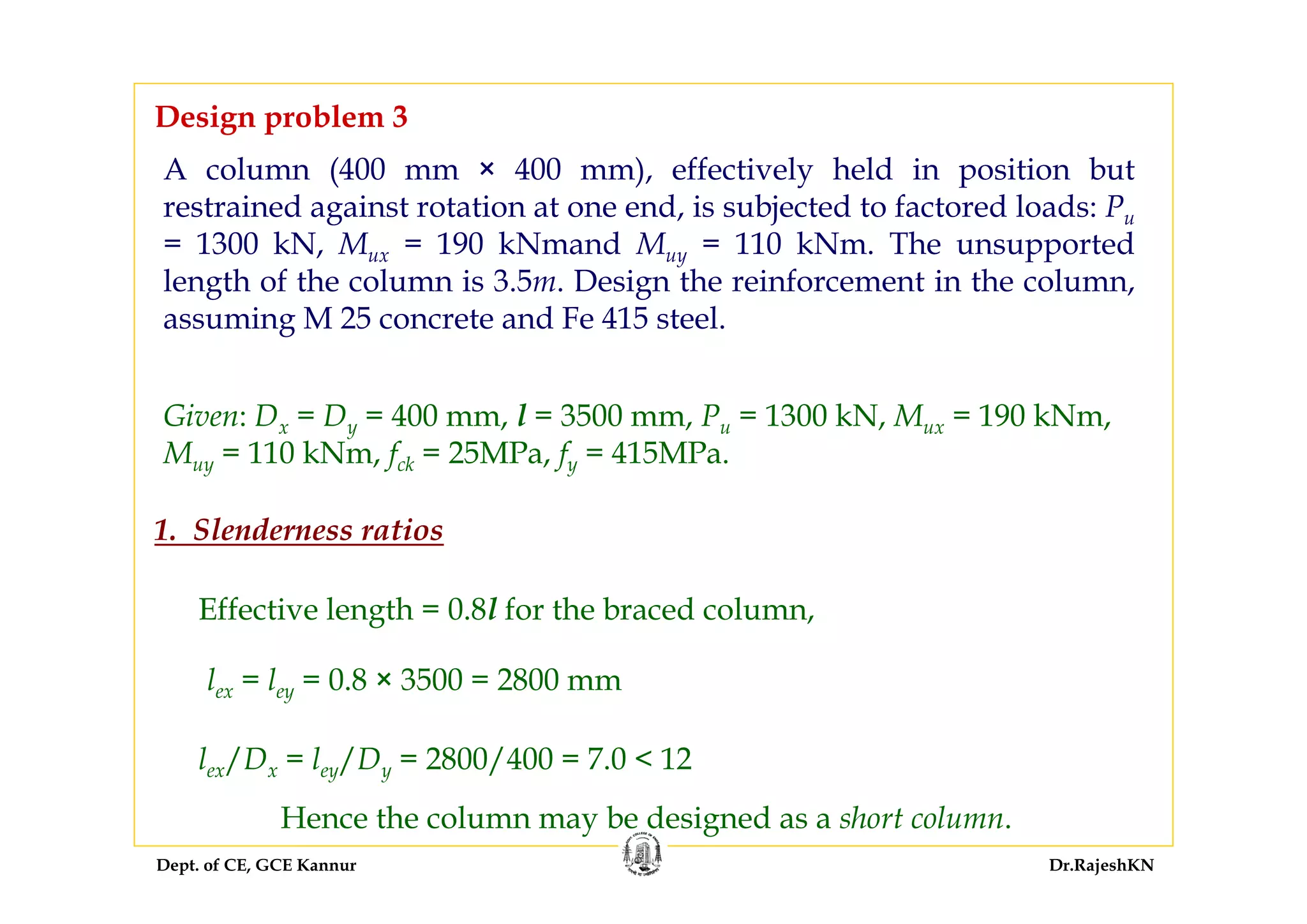

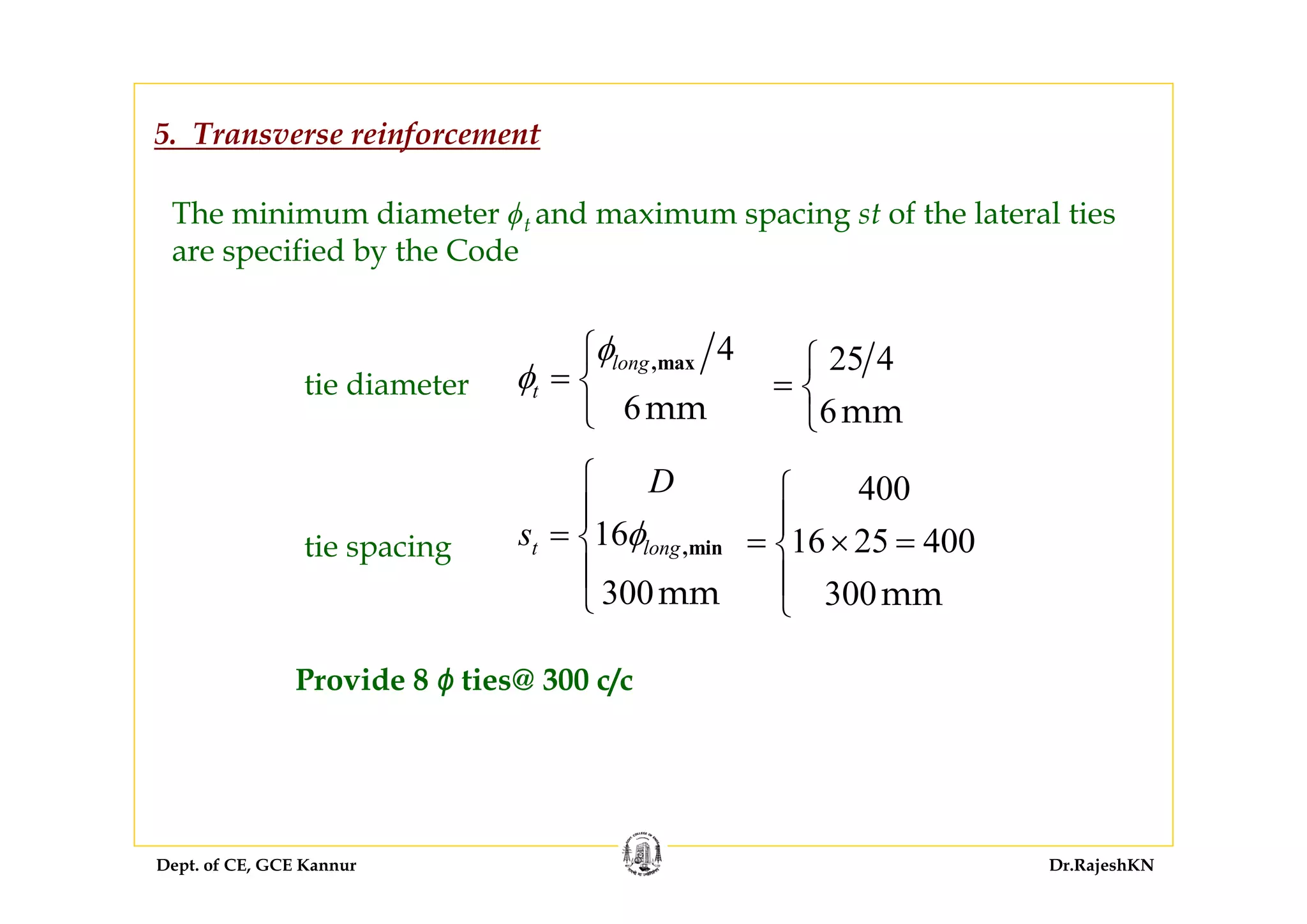

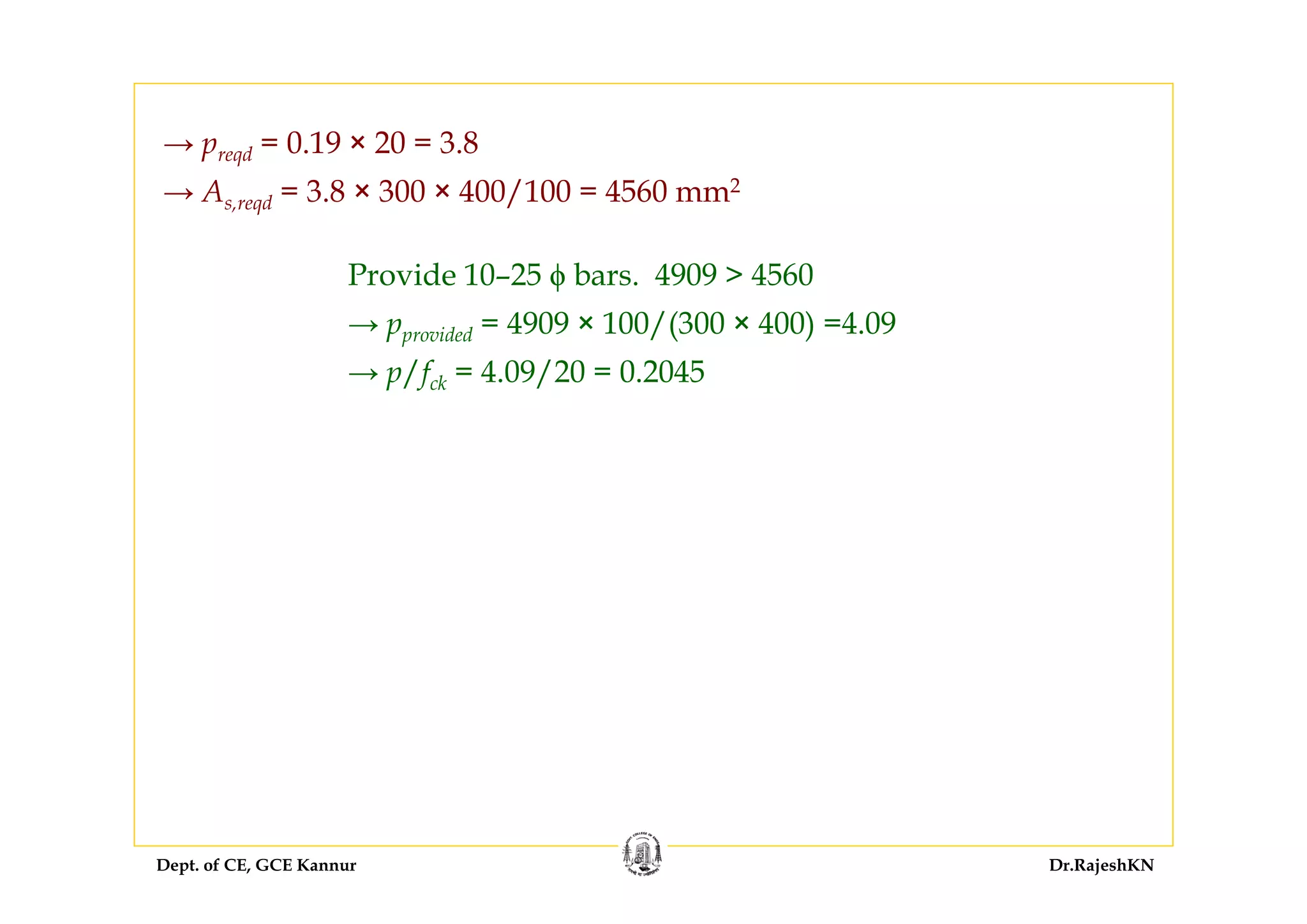

→ preqd = 0.13 × 30 = 3.9

→ As,reqd = 3.9 × 300 × 400/100 = 4680 mm2

Provide 8–28 ϕ [As = 8 × 616 mm2] 4928 > 4680

→ pprovided = 4928 × 100/(300 × 400) =4.107

→ p/fck = 4.107/30 = 0.137](https://image.slidesharecdn.com/sd-i-module4-rajeshsir-140806050206-phpapp02/75/Sd-i-module4-rajesh-sir-69-2048.jpg)

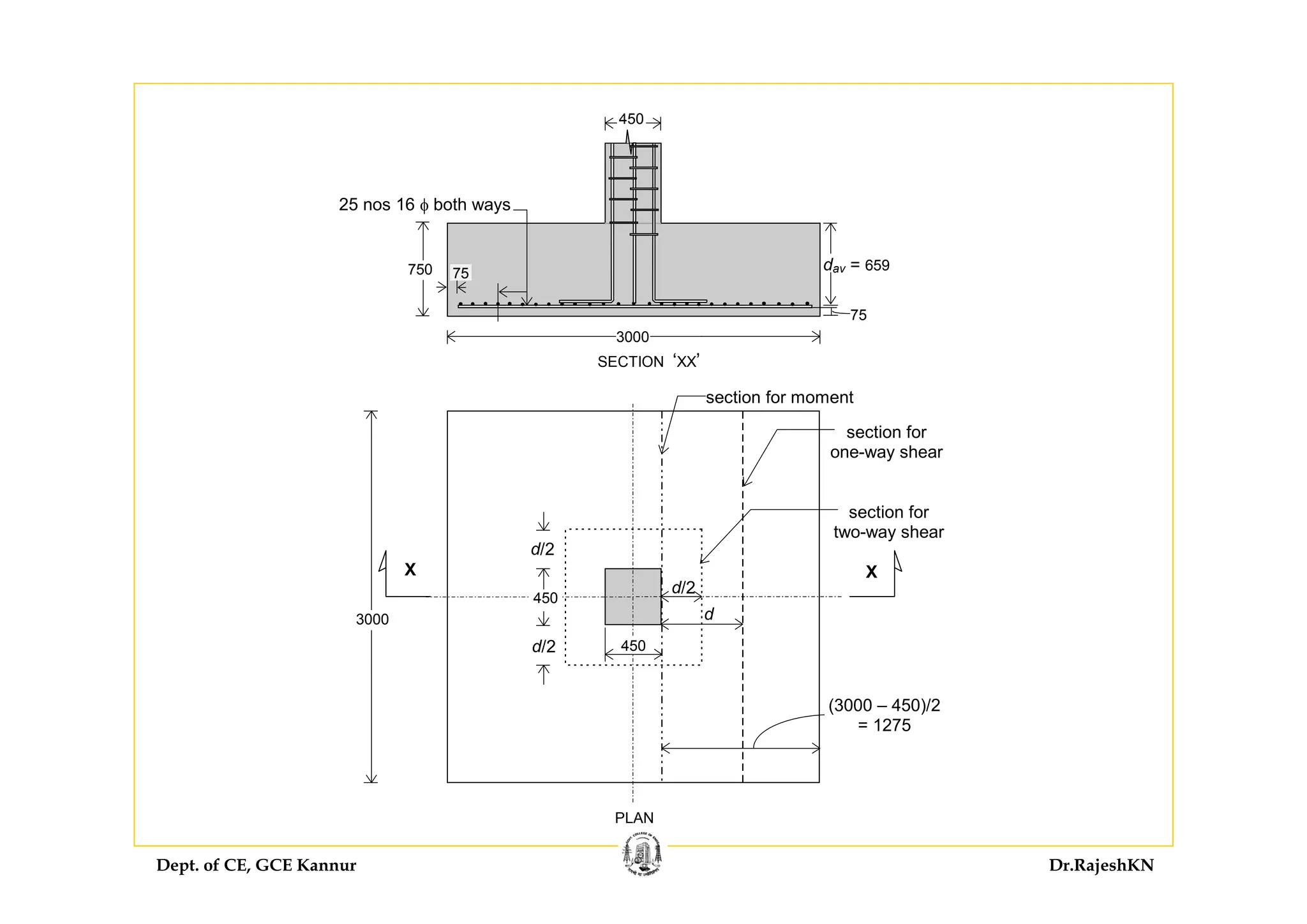

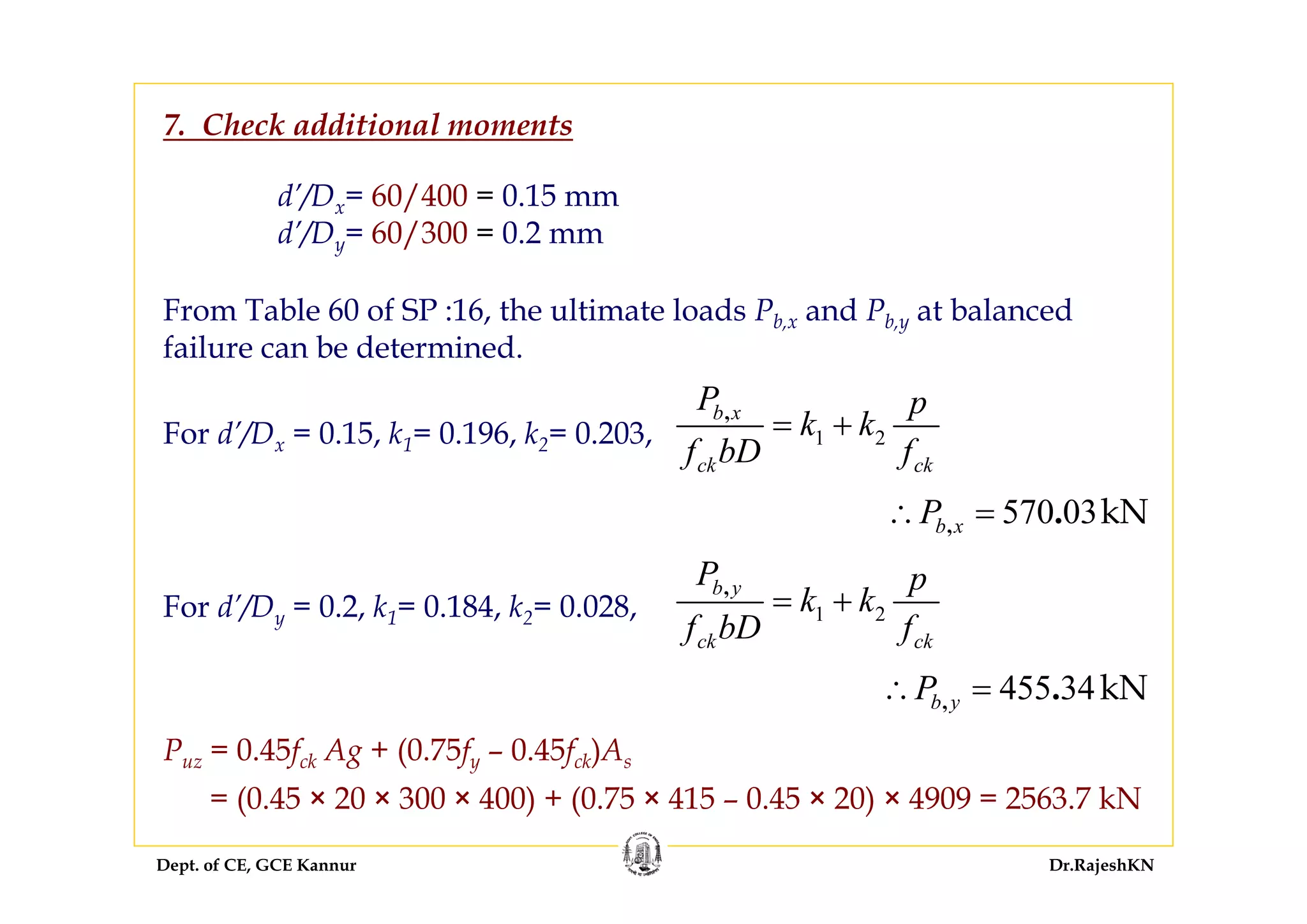

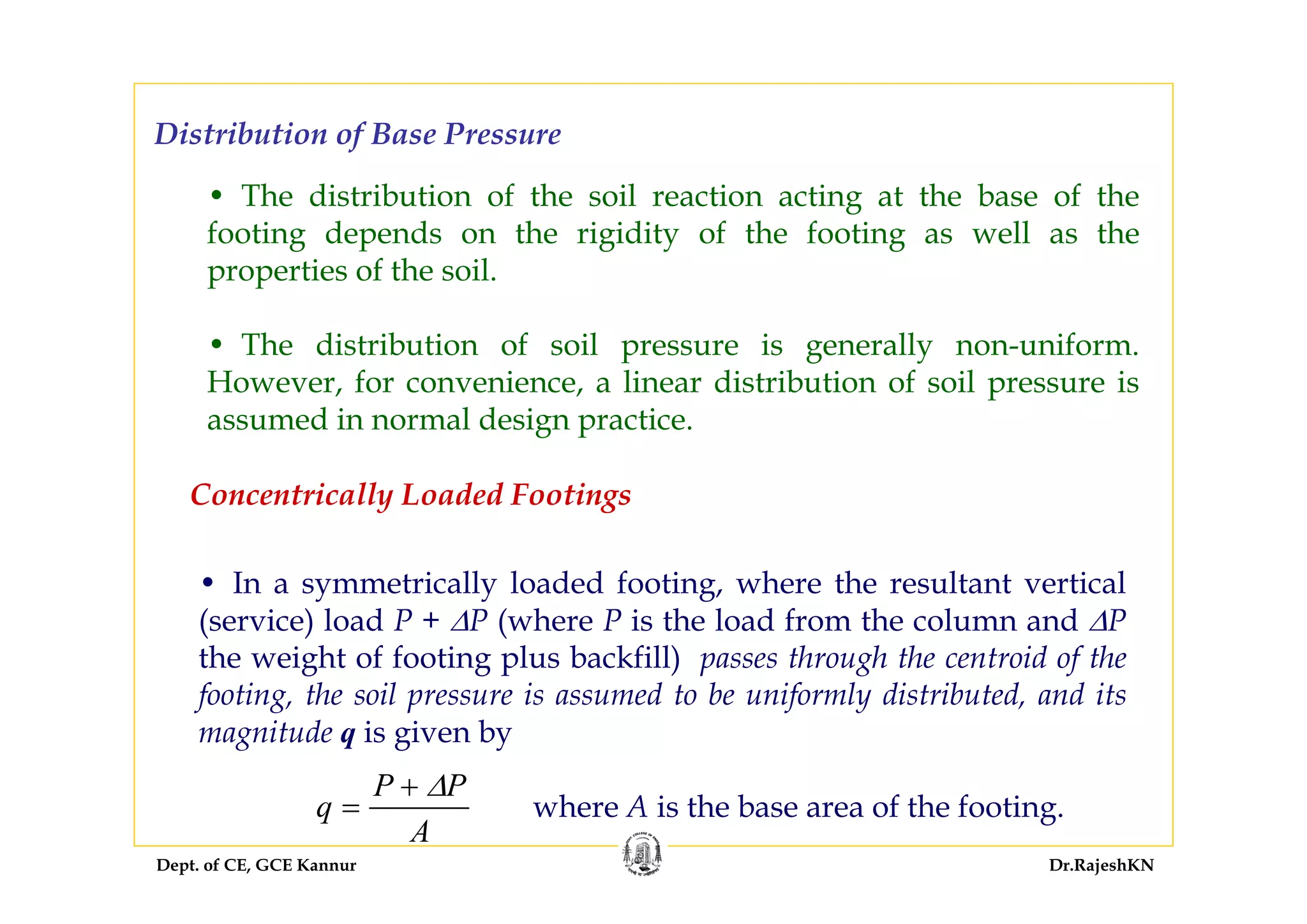

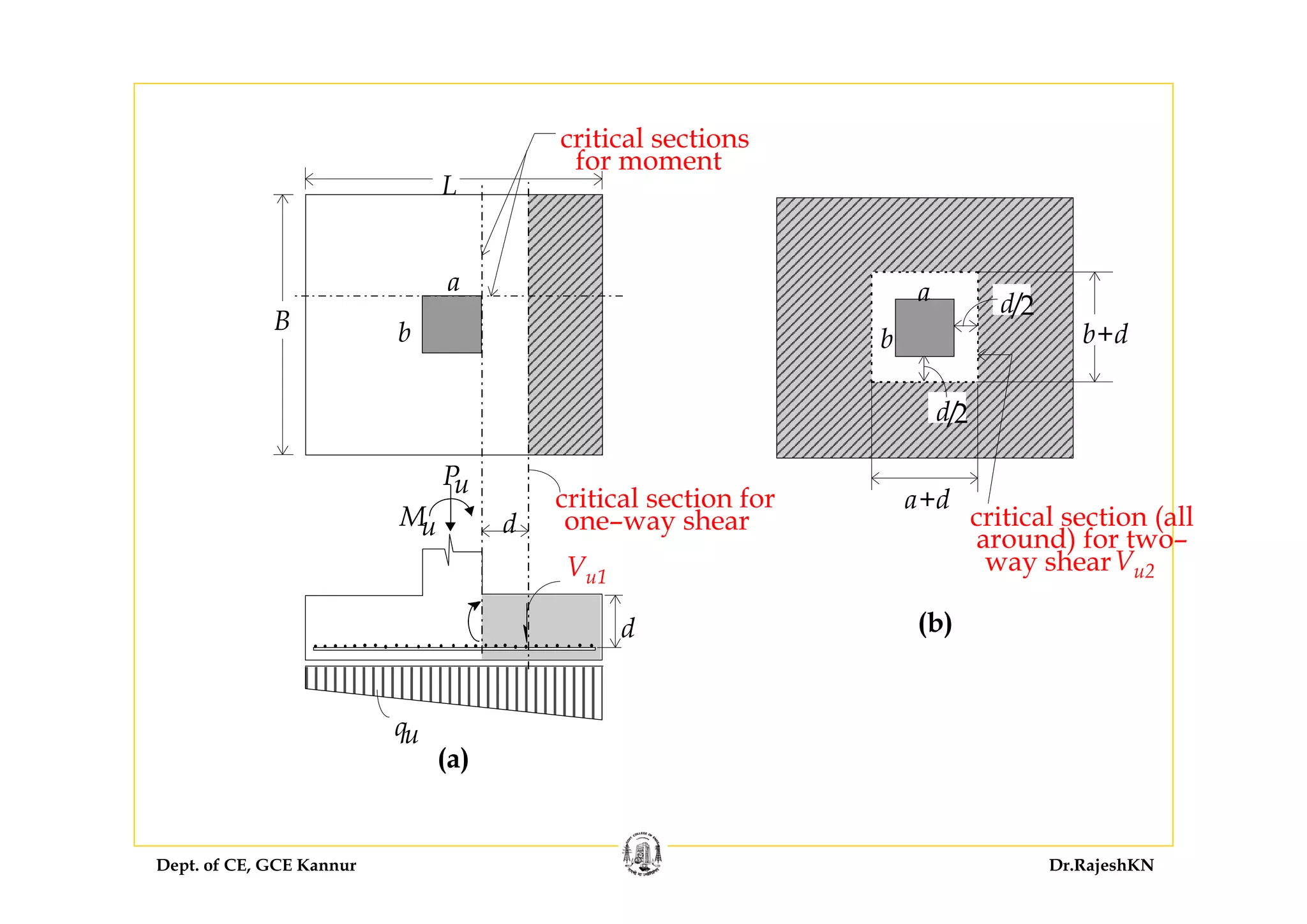

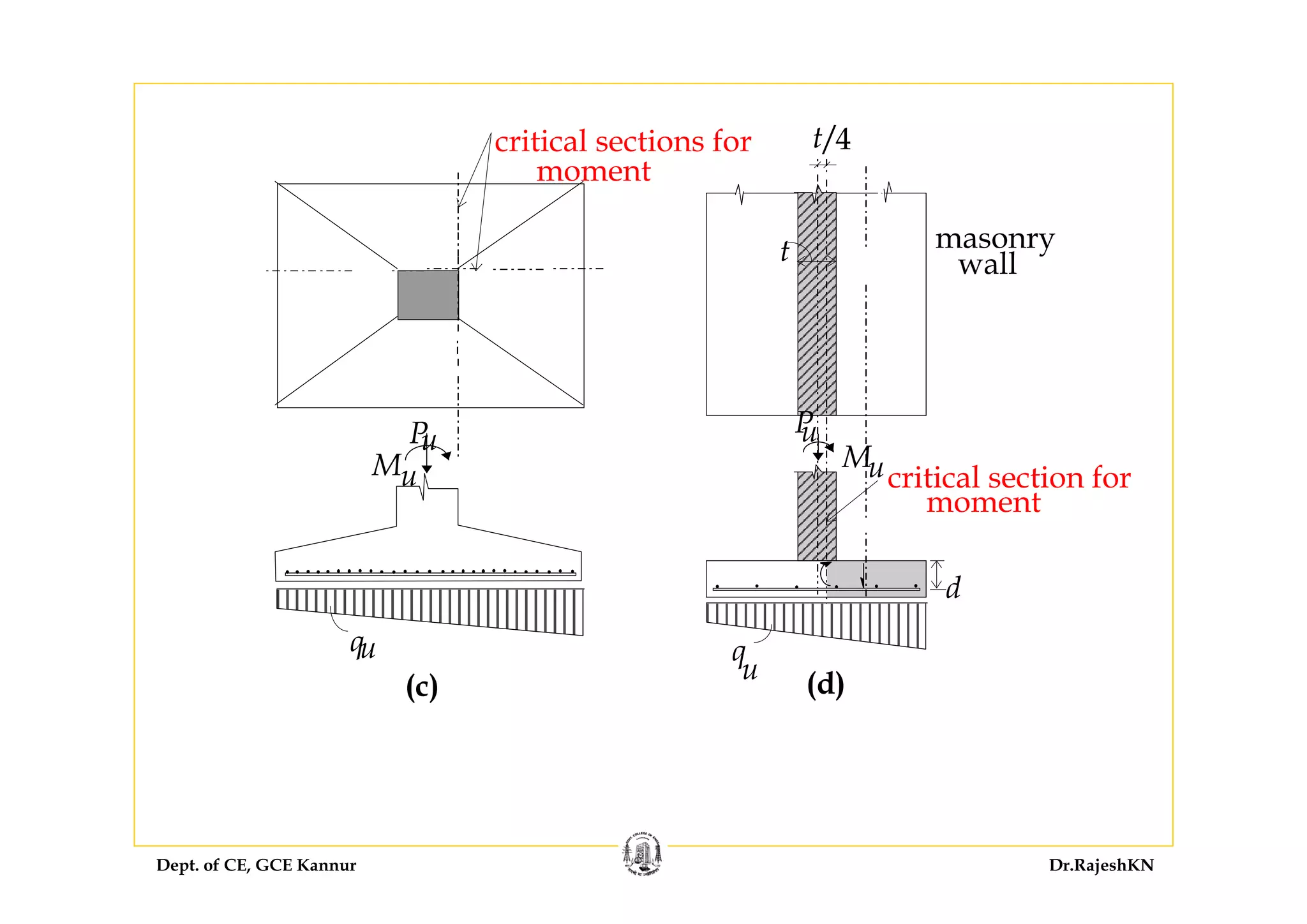

![Dept. of CE, GCE Kannur Dr.RajeshKN

Thickness of Footing Base Slab

• The thickness of a footing base slab is generally based on

considerations of shear and flexure, which are critical near the

column location.

• Generally, shear considerations predominate, and the thickness is

based on shear criteria.

Both one-way shear and two-way shear (‘punching shear’) need to

be considered [Cl. 34.2.4.1].](https://image.slidesharecdn.com/sd-i-module4-rajeshsir-140806050206-phpapp02/75/Sd-i-module4-rajesh-sir-86-2048.jpg)

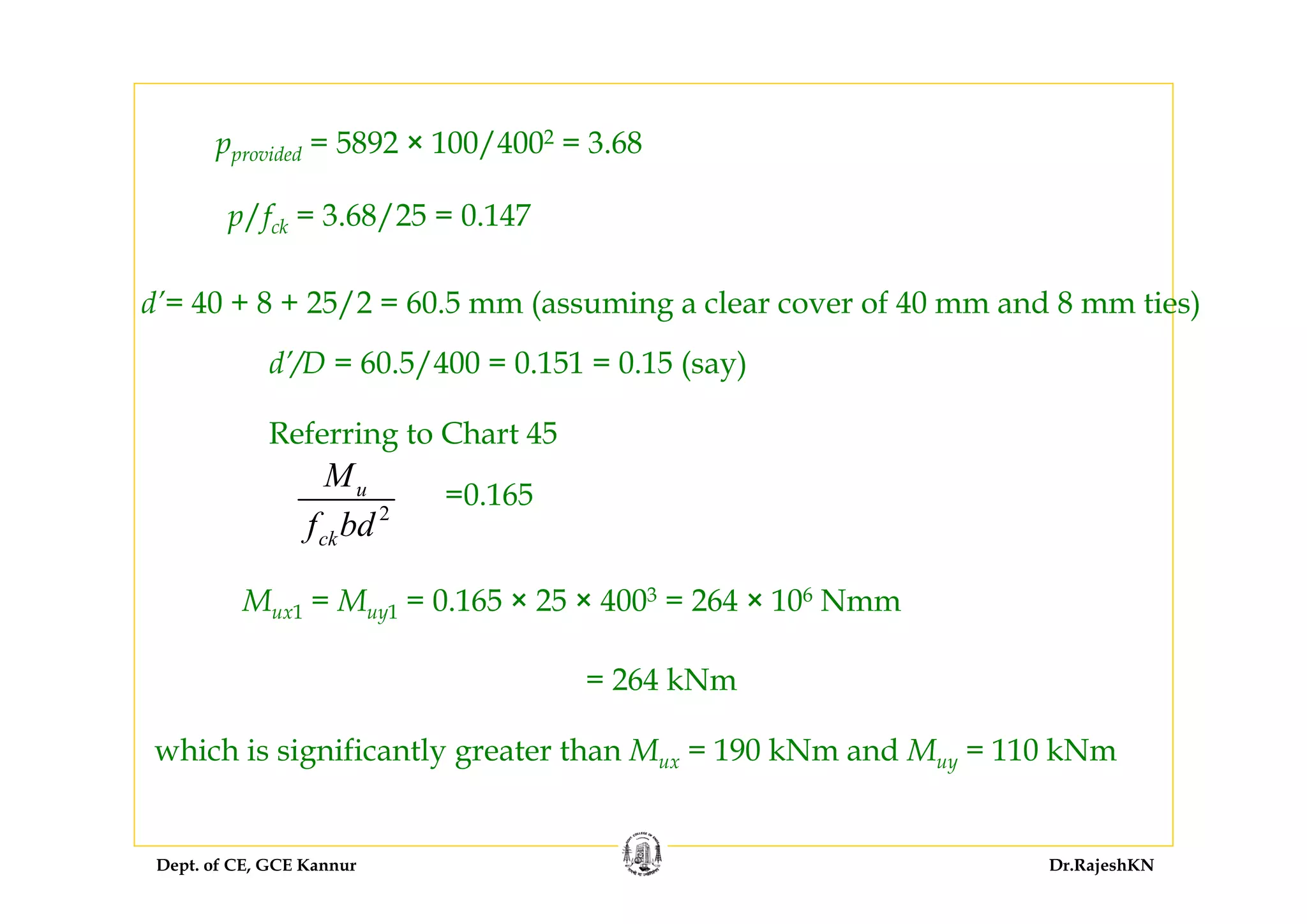

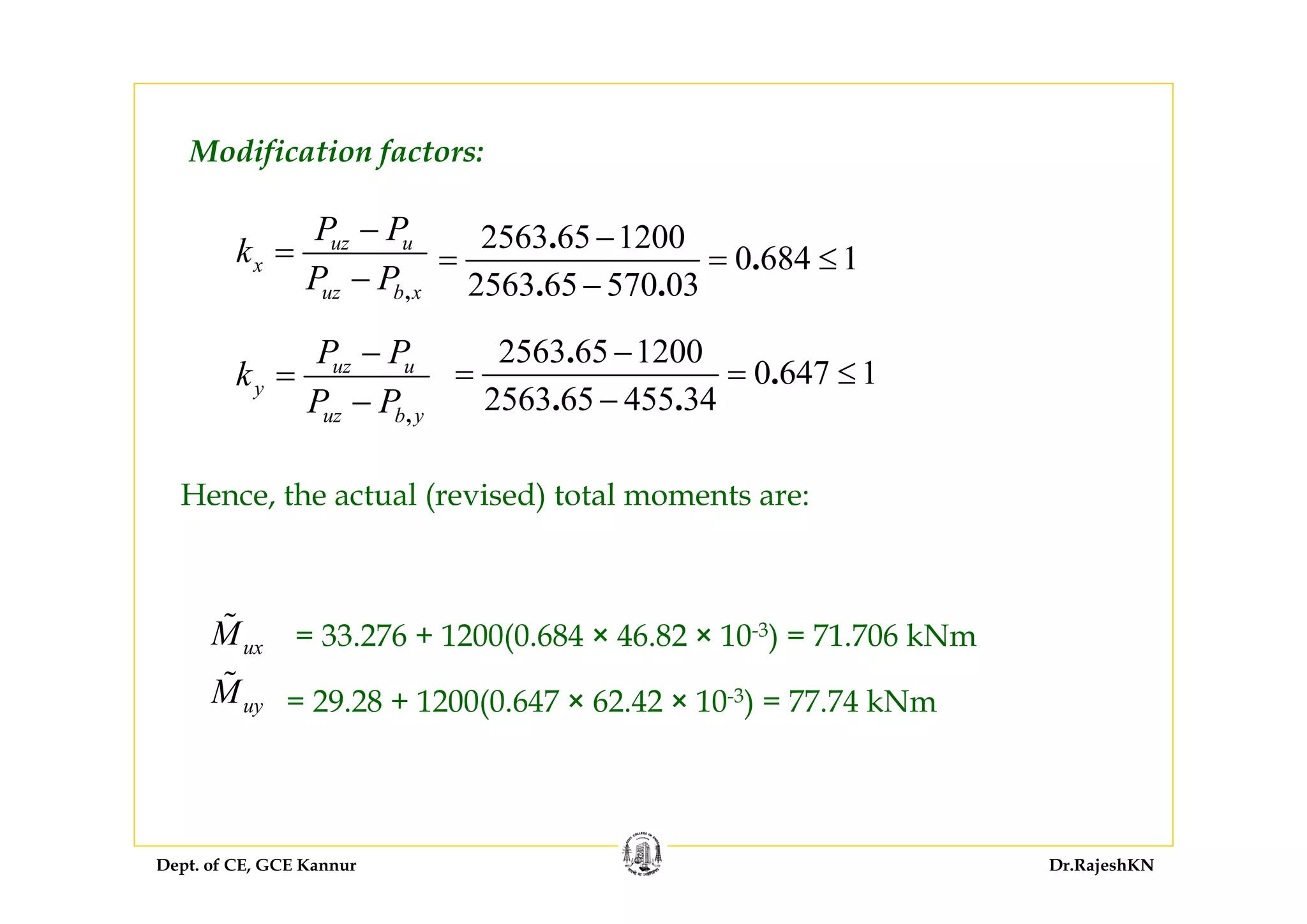

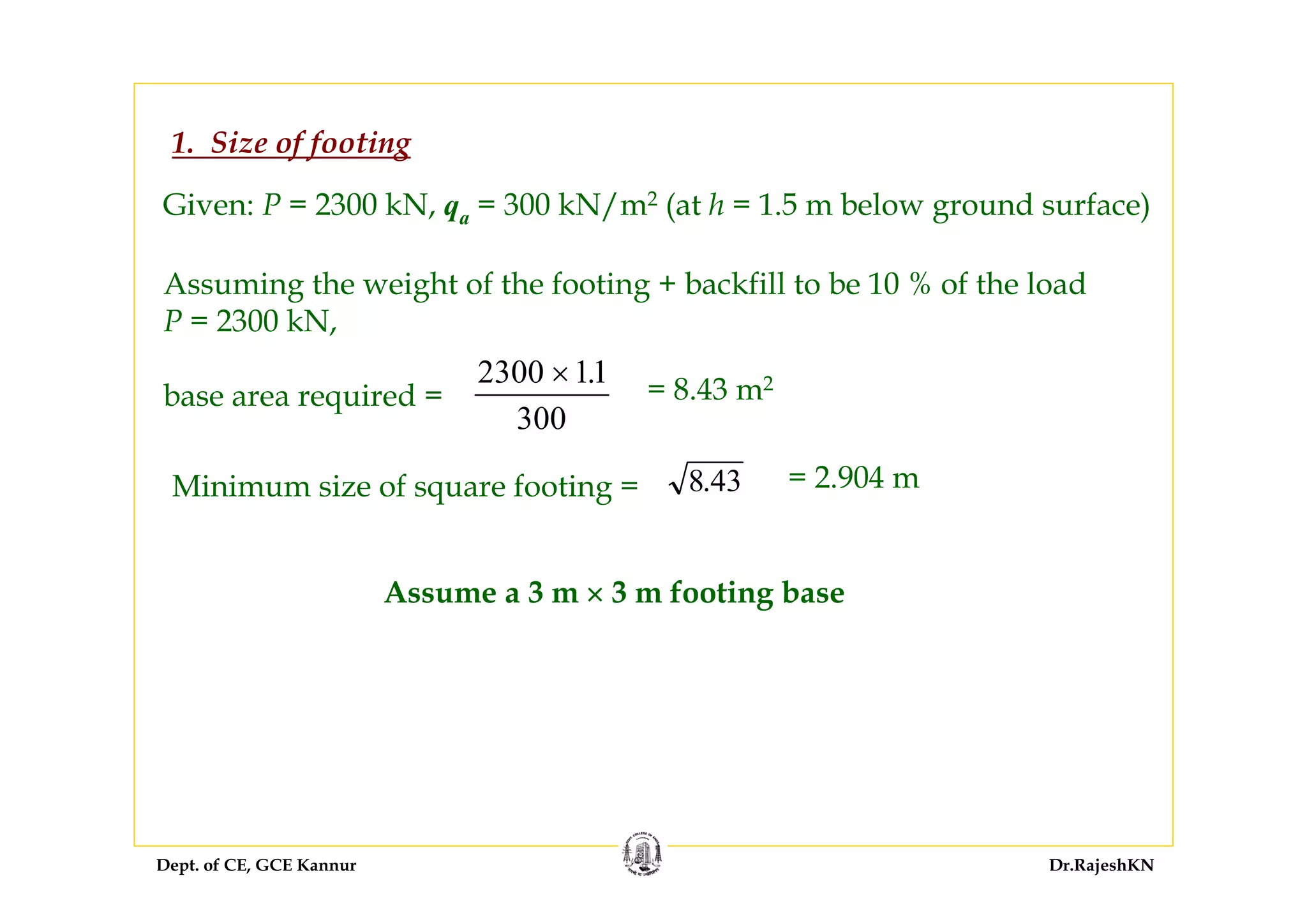

![Dept. of CE, GCE Kannur Dr.RajeshKN

Assuming 0 36 MPa.cτ =

(for M 20 concrete with, say, pt = 0.25) [Table 19],

One-way shear resistance Vc1 = 0.36 × 3000 × d = (1080d) N

Vu1 ≤ Vc1

1464975 – 1149d ≤ 1080d

d ≥ 658 mm](https://image.slidesharecdn.com/sd-i-module4-rajeshsir-140806050206-phpapp02/75/Sd-i-module4-rajesh-sir-92-2048.jpg)

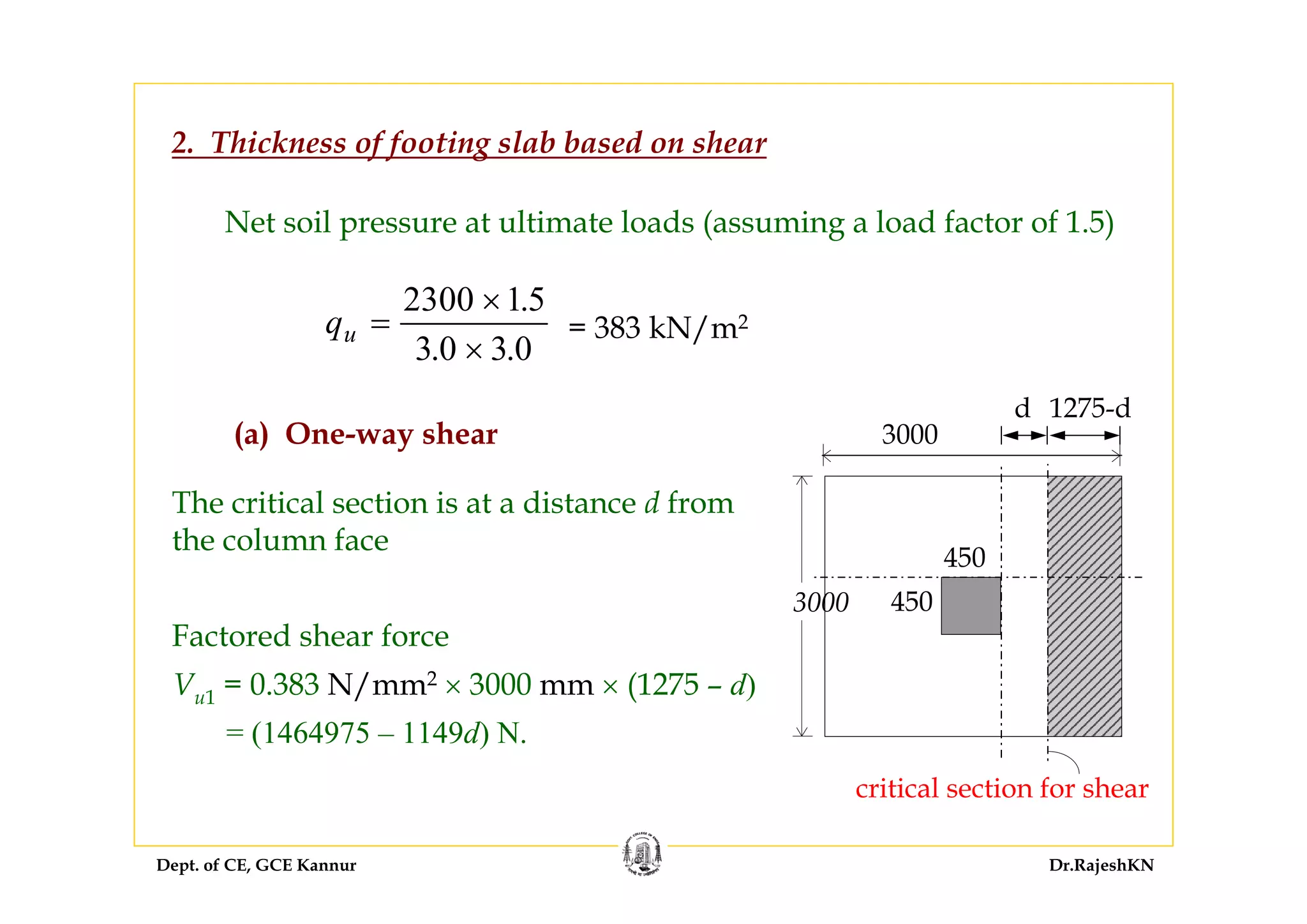

![Dept. of CE, GCE Kannur Dr.RajeshKN

(b) Two-way shear

The critical section is at d/2 from the periphery of the column

⇒ Factored shear force Vu2 = 0.383 × [30002 – (450 + d)2]

Two-way shear resistance

( )2 4 450c s cV k d dτ ⎡ ⎤= × × +⎣ ⎦

where ks = 1.0 for a square column

0 25 20.cτ =

= 1.118 MPa (Cl. 31.6.3.1)

450

450

d/2

d/2

critical section (all

around) for two–

way shear Vu2

450+d

450+d](https://image.slidesharecdn.com/sd-i-module4-rajeshsir-140806050206-phpapp02/75/Sd-i-module4-rajesh-sir-93-2048.jpg)

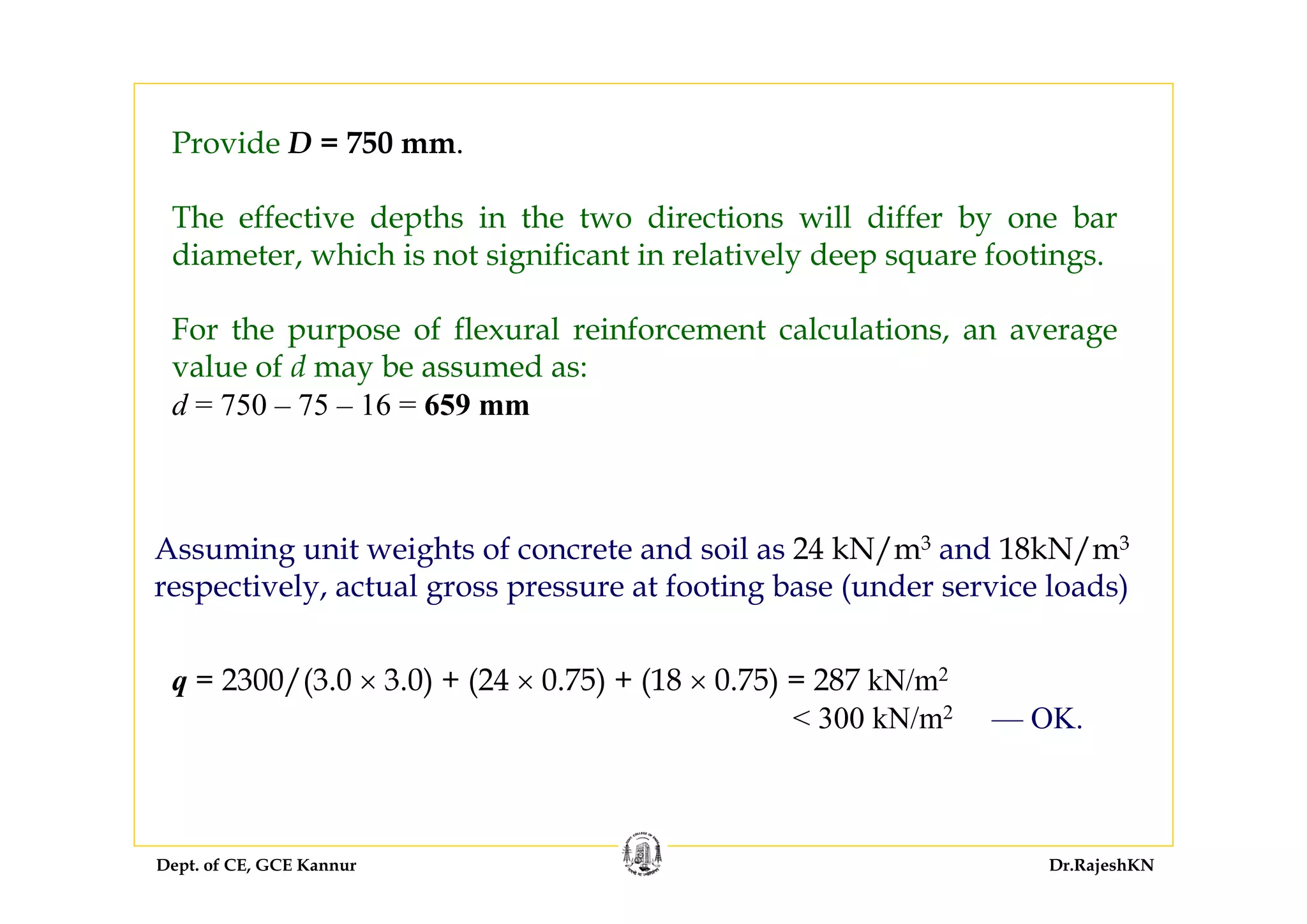

![Dept. of CE, GCE Kannur Dr.RajeshKN

Vc2 = 1.0 × 1.118 × 4d (450 + d)

= (2012.4d + 4.472d2) N

Evidently, in this problem, one-way shear governs the thickness.

Assuming a clear cover of 75 mm and 16 φ bars in both directions,

with an average d = 658 mm,

thickness D ≥ 658 + 75 + 16 = 749 mm

Vu2 ≤ Vc2 ⇒ 0.383 × [30002 – (450 + d)2] ≤ 2012.4d + 4.472d2

3369442.5 - 0.383 d2 - 900d ≤ 2012.4d + 4.472d2

4.855 d2 + 2912.4 d - 3369442.5 ≥ 0

d ≥ 585.5](https://image.slidesharecdn.com/sd-i-module4-rajeshsir-140806050206-phpapp02/75/Sd-i-module4-rajesh-sir-94-2048.jpg)

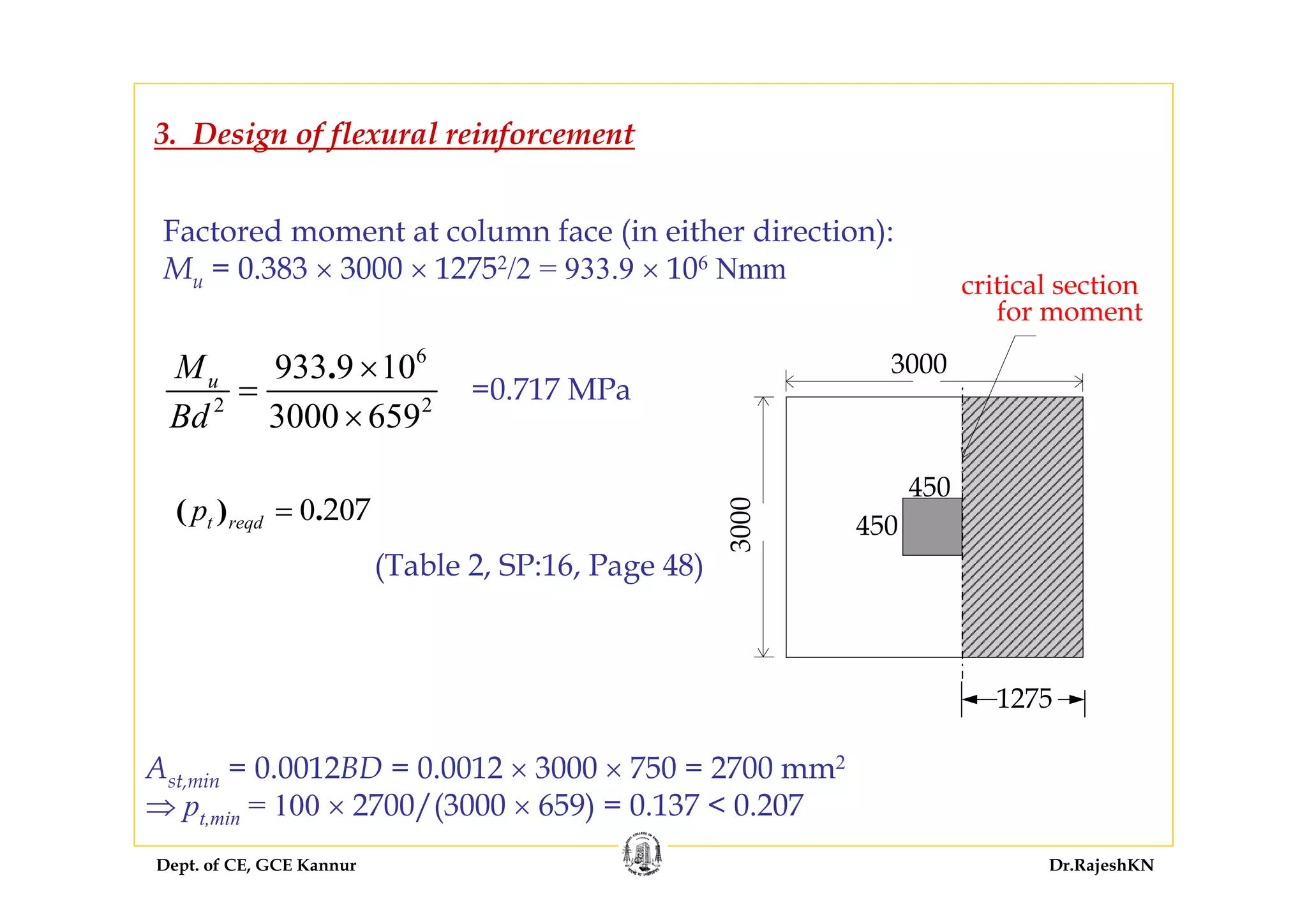

![Dept. of CE, GCE Kannur Dr.RajeshKN

But this reinforcement is less than the 0.25% assumed for one-way shear.

Hence Ast,reqd = 0.25 × 3000 × 659/100 = 4943 mm2

Using 16 mm φ bars, number of bars required = 4943/201 = 25

[corresponding spacing s = {3000 – (75 × 2) – 16}/(25 –1) = 118 mm —

is acceptable.]

Provide 25 nos 16 φ bars both ways

Required development length

( )0 87

4

. y

d

bd

f

L

φ

τ

= Cl. 26.2.1

For M 20 concrete and Fe 415 steel,

0 87 415

47

4 1 2 1 6

.

. .

dL φ φ

×

= =

× ×

For 16 φ bars in footing, Ld = 47.0 × 16 = 752 mm

Length available = 1275 – 75 = 1200 mm > 752 mm — Hence, OK.](https://image.slidesharecdn.com/sd-i-module4-rajeshsir-140806050206-phpapp02/75/Sd-i-module4-rajesh-sir-97-2048.jpg)