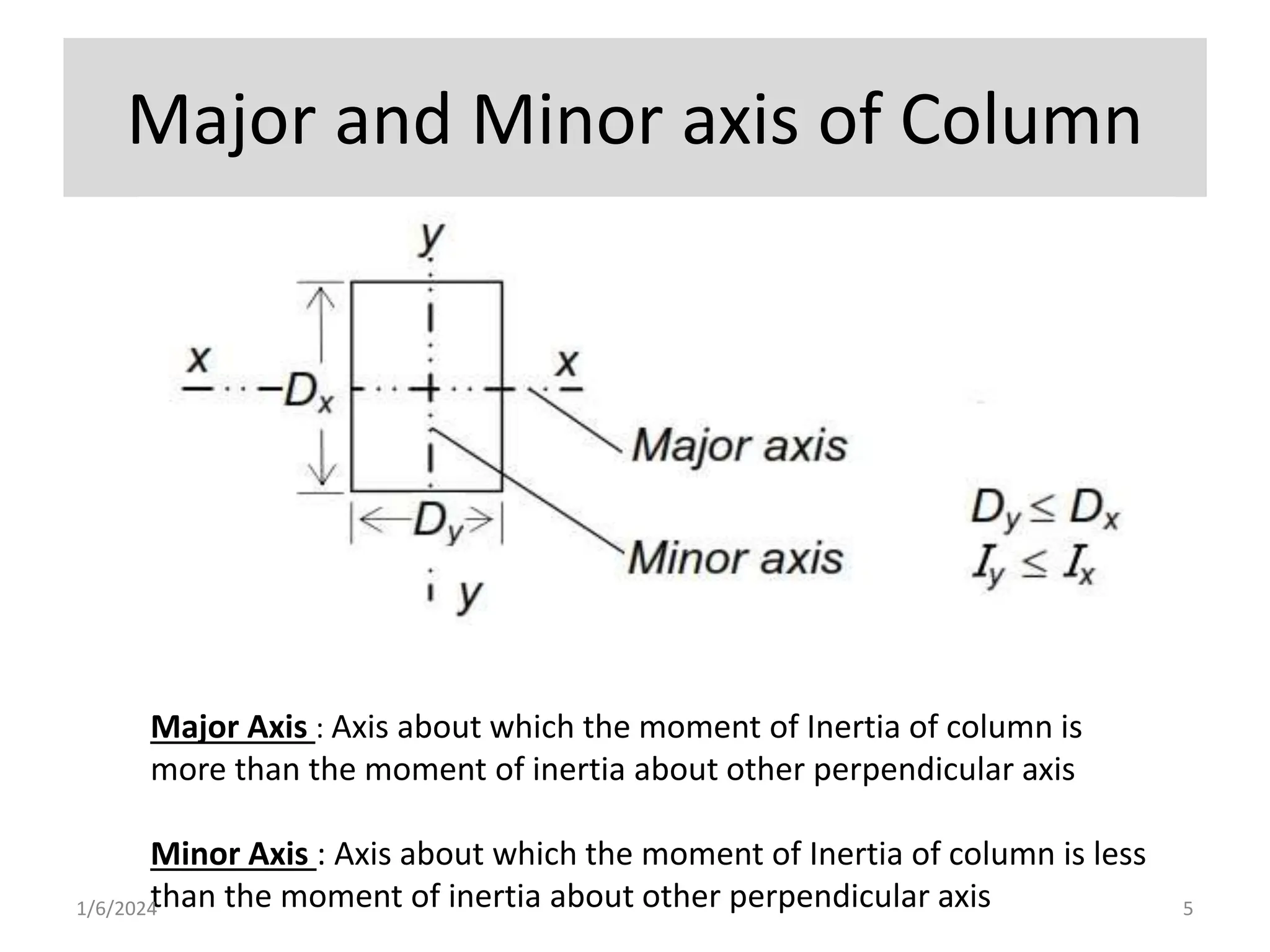

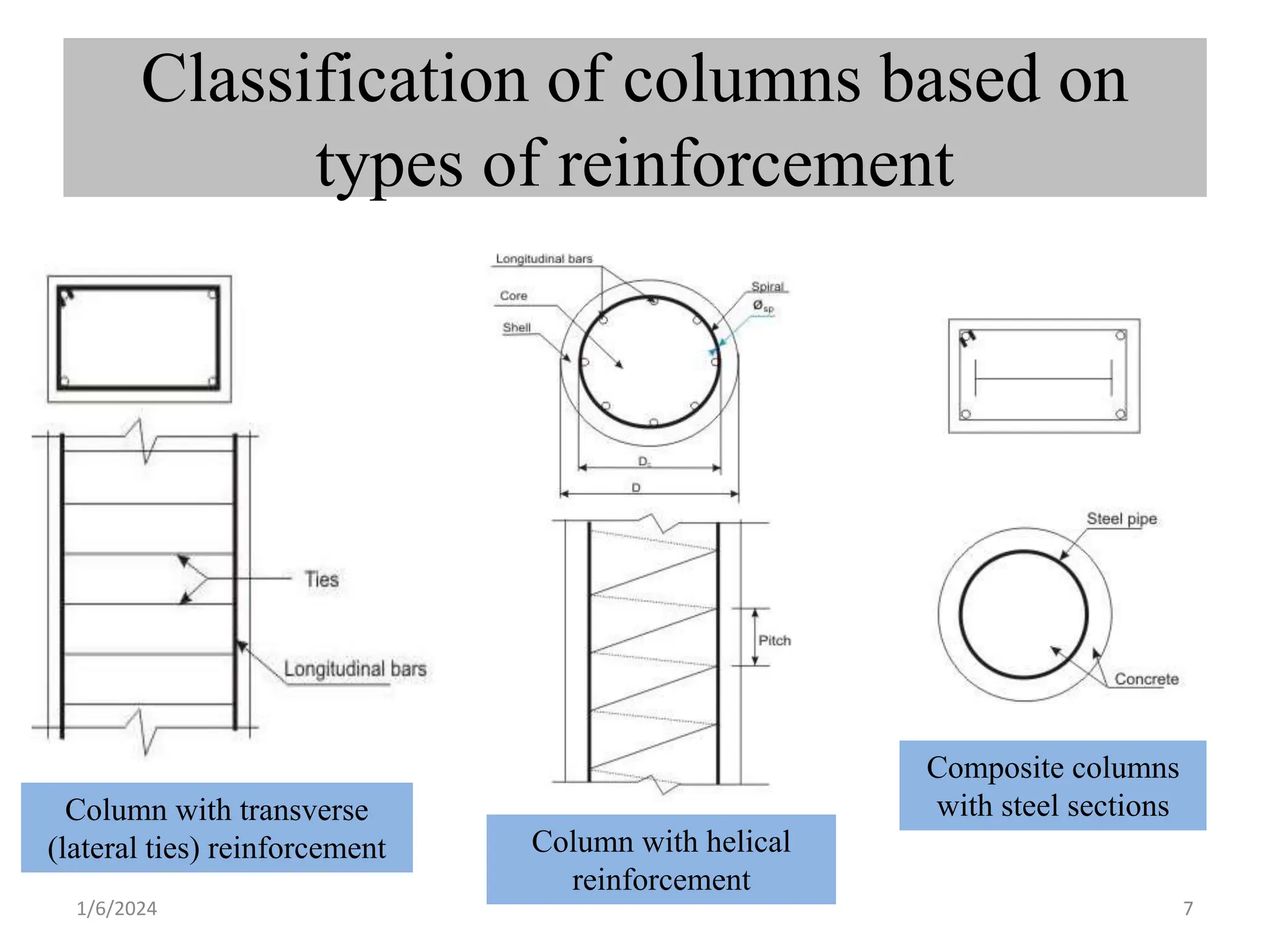

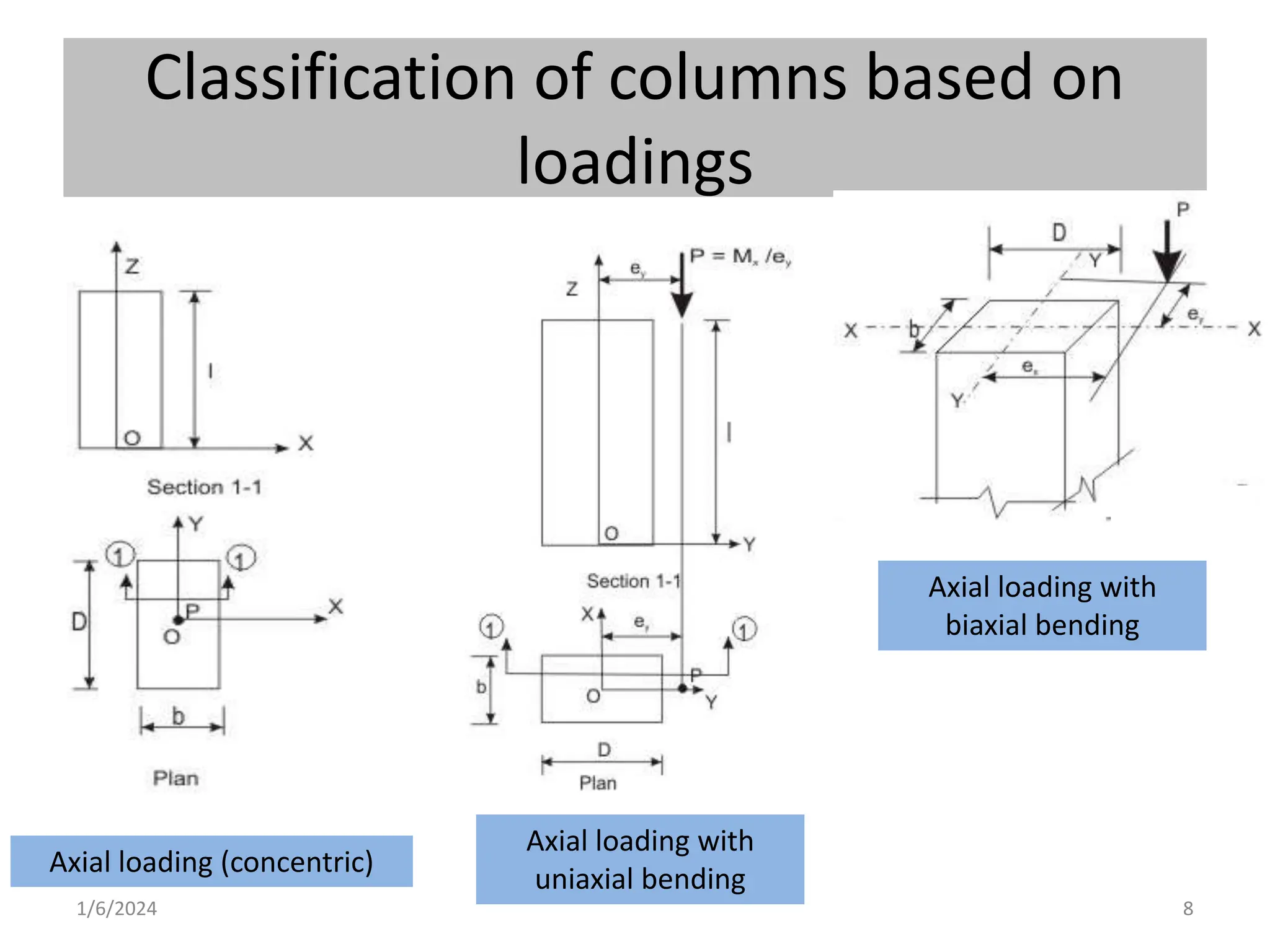

The document discusses various types of compression members including columns, pedestals, walls, and struts. It describes design considerations for compression members including strength and buckling resistance. It defines effective length as the vertical distance between points of inflection when the member buckles. Various classifications of columns are discussed based on loadings, slenderness ratio, and reinforcement type. Code requirements for longitudinal and transverse reinforcement as well as detailing are provided. Two examples of column design are included, one with axial load only and one with spiral reinforcement.