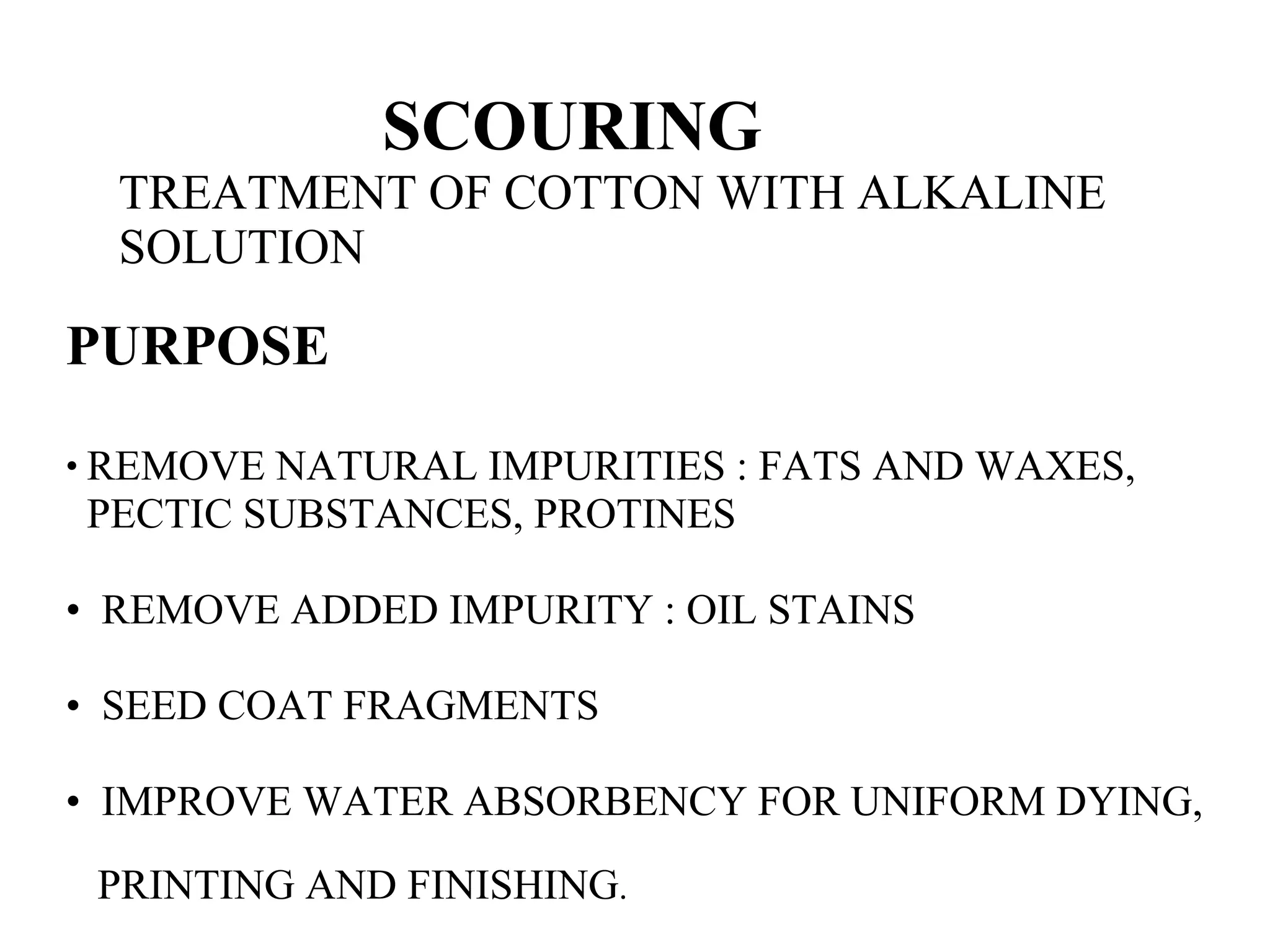

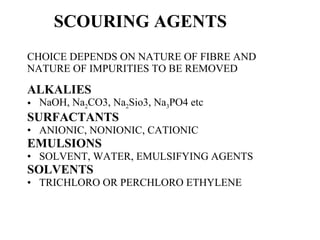

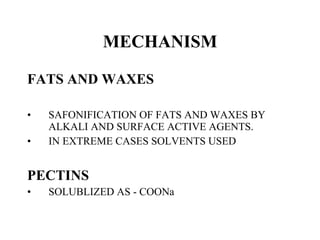

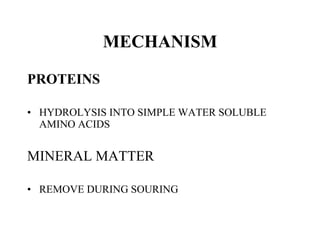

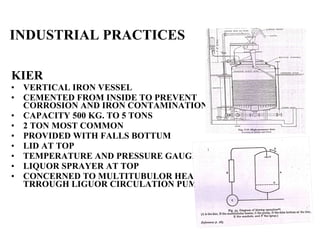

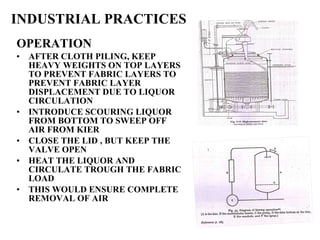

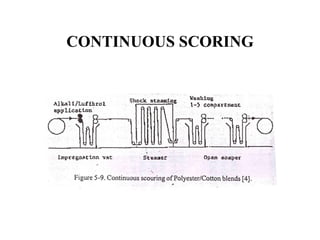

The document discusses the scouring process for cotton fabrics. Scouring removes natural and added impurities from cotton using alkaline solutions, surfactants, and sometimes solvents. Common scouring methods include caustic soda boiling, soda ash boiling, and continuous scouring using pad steam processes. The scouring process improves cotton's absorbency and prepares it for further treatments like dyeing and finishing.