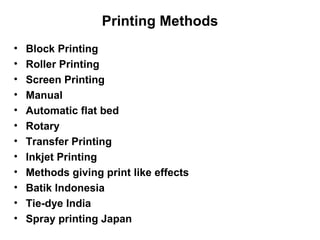

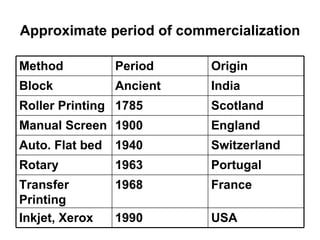

1. The document discusses various textile printing methods and the shift from traditional to digital printing technologies.

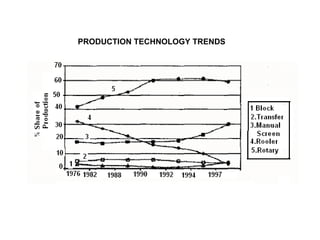

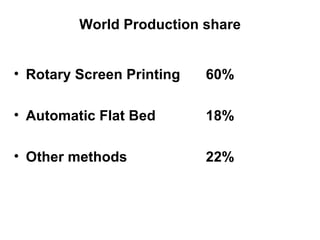

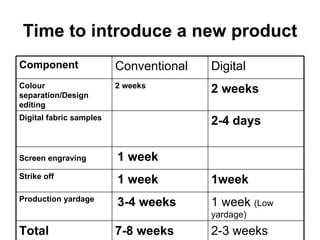

2. Rotary screen printing currently dominates world production at 60% but is slow and expensive for small batch and customized orders.

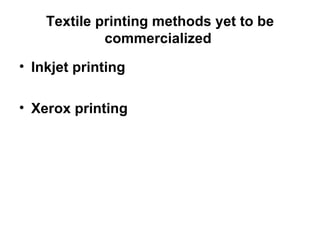

3. New technologies like inkjet and xerography printing allow for mass customization with fast design changes, computerized processes, and on-demand manufacturing to meet trends of short lead times and one-off orders.

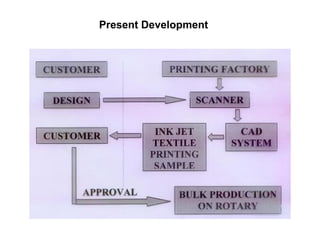

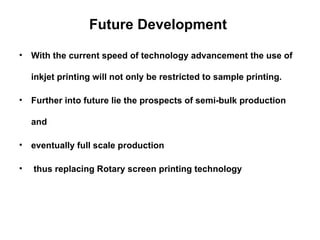

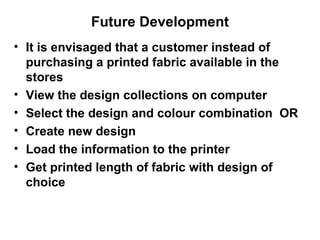

4. Inkjet printing is seen as the future of textile printing, replacing rotary screen printing by enabling semi-bulk and full scale customized production directly from a customer's computer design files.