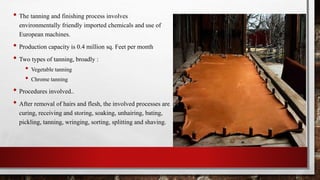

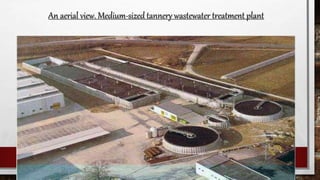

Tanning is the process of converting animal hides and skins into leather through chemical treatments. This document describes the tanning process and the tannery industry in Bangalore, India. It discusses the types of chemicals used in tanning, the characteristics of tannery wastewater, and the treatment methods used, including physical separation processes, chemical coagulation and flocculation, sedimentation, biological treatments, and sludge management. The major tannery area in Bangalore is located on Tannery Road, which has around 700 leather shops.