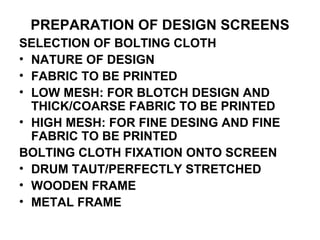

Manual screen printing is a modified version of stencil printing that was developed in England in the 1830s-1840s and became popular in India in the 1920s. It remains most commonly used by small-scale printers. The process involves stretching a bolting cloth screen fabric tightly over a frame, coating it with a photosensitive emulsion, exposing the screen to a color-separated design to insolubilize the emulsion, and washing away the unexposed emulsion to create stencil openings. The screen is then ready to use to force ink through the stencil openings and transfer the design to fabric by moving a squeegee over the screen surface.