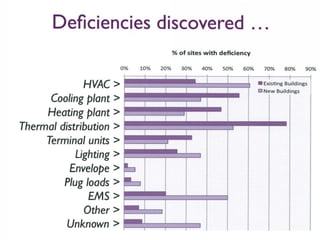

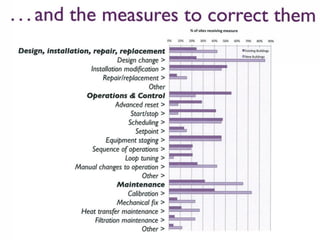

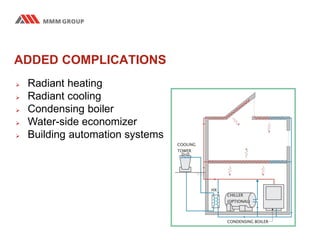

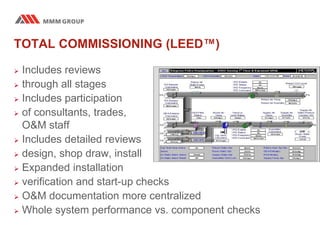

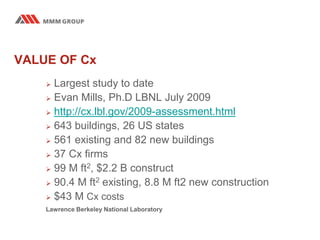

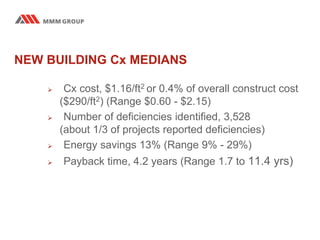

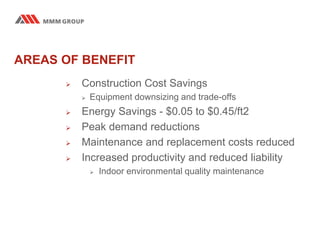

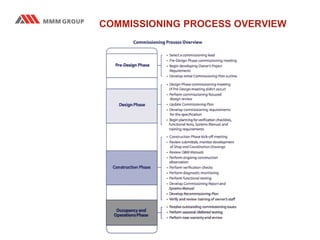

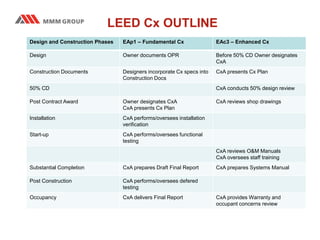

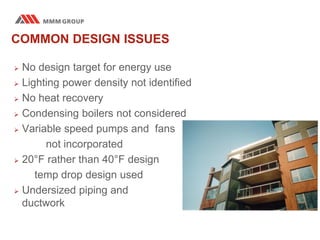

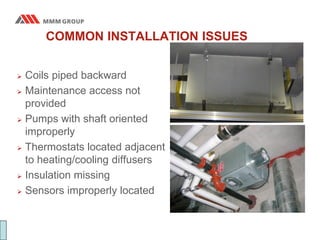

The document outlines the importance and process of building commissioning in construction projects, emphasizing the need for quality assurance to meet owner project requirements. It describes the roles of various stakeholders, including the commissioning authority, owners, and contractors, in achieving energy efficiency and operational performance. The document also highlights the benefits of thorough commissioning, including cost savings and improved indoor environmental quality.