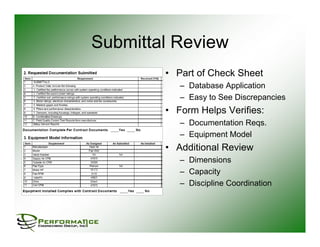

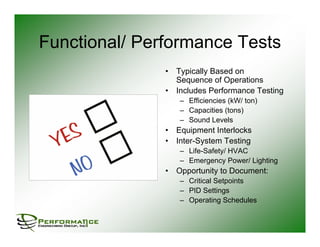

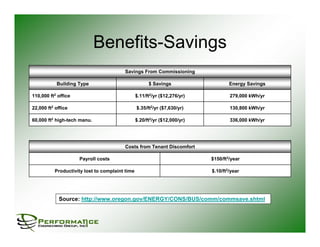

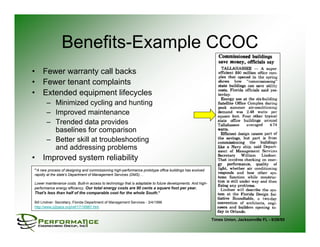

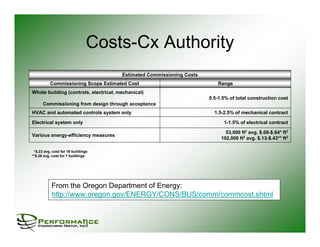

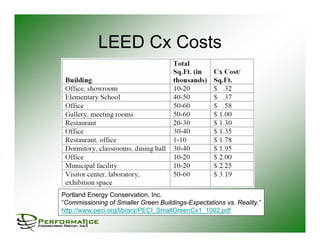

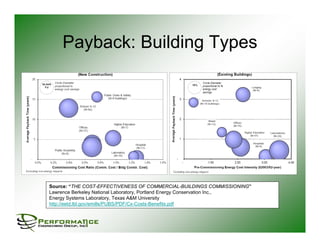

The document discusses the commissioning process for new facilities. It defines commissioning and its purpose to ensure building systems meet the owner's requirements. It outlines the commissioning process, including developing owner's project requirements and a basis of design, reviewing designs, creating test plans and manuals, and following up after occupancy. The benefits of commissioning are improved system performance, indoor air quality, energy efficiency, and lower lifetime costs. Costs for commissioning range from 0.5-2.5% of construction costs depending on the project scope.