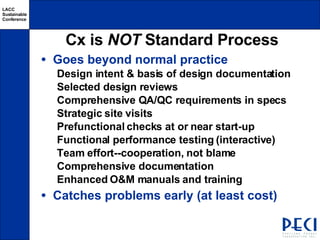

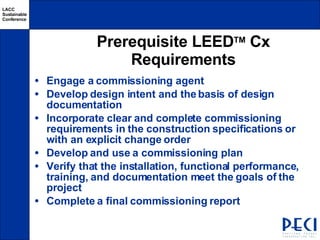

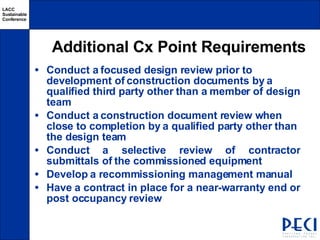

- Commissioning is a quality assurance process that ensures building systems are designed and installed properly to operate as intended. It identifies problems early to reduce costs.

- A 1994 study found over half of commercial buildings had HVAC or control problems, showing the need for commissioning.

- Commissioning verifies design intent is met and ensures systems function interactively as intended through testing and documentation. This improves performance and reduces long term costs.