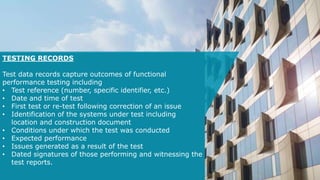

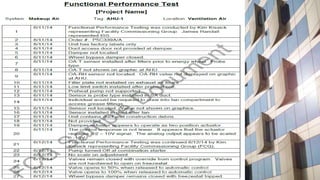

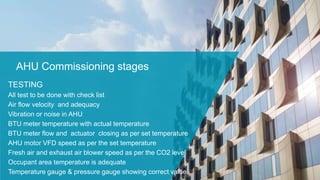

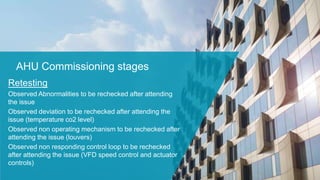

The document provides guidelines for commissioning and handing over a building from the project team to the facility operations team. It discusses the importance of involving the facility team early in the design process and having them lead the commissioning and testing. The commissioning should be done in stages from pre-commissioning to testing to documentation. Training of the facility team is also emphasized. An example commissioning process for an air handling unit is provided to illustrate the different stages.