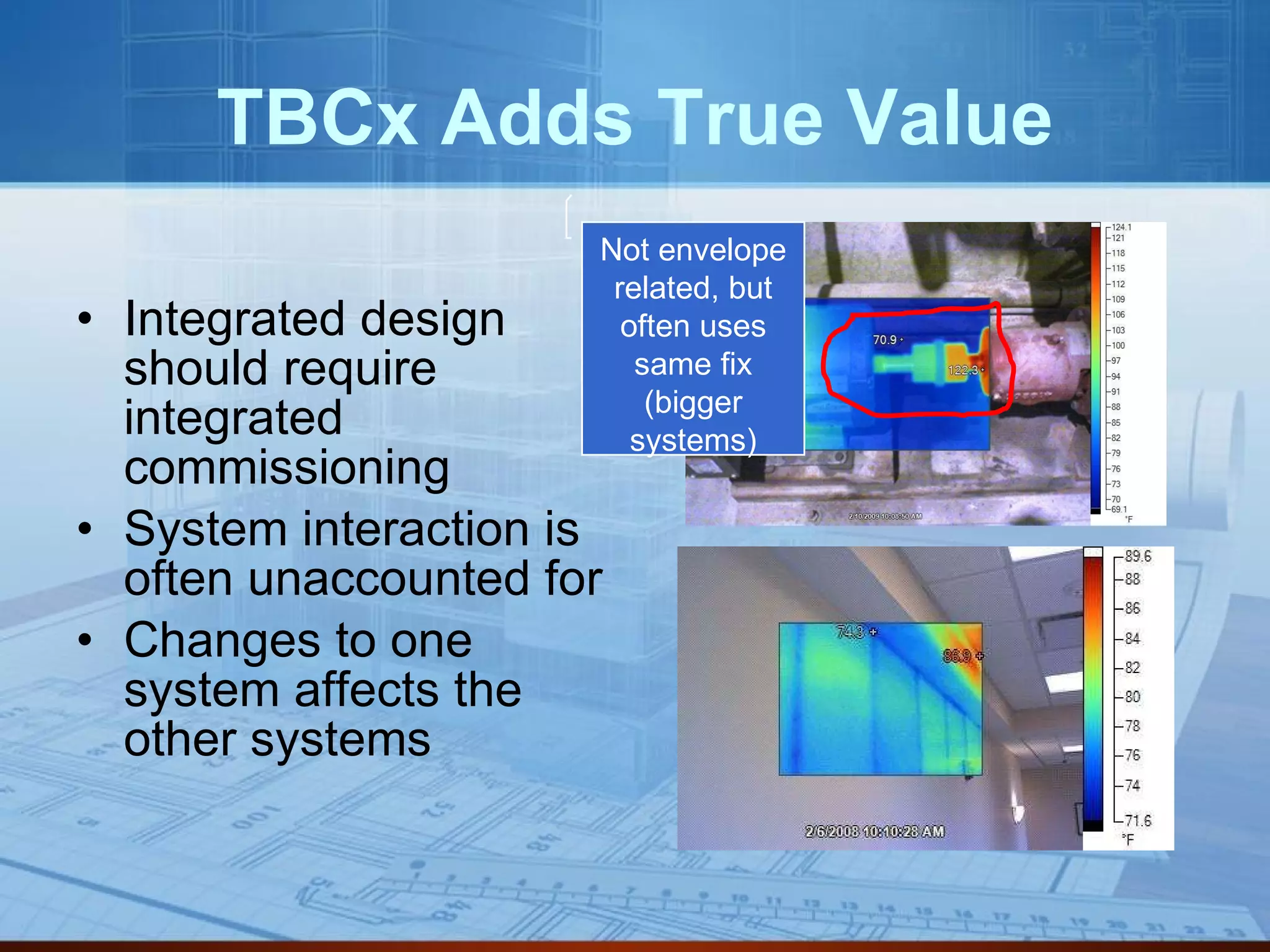

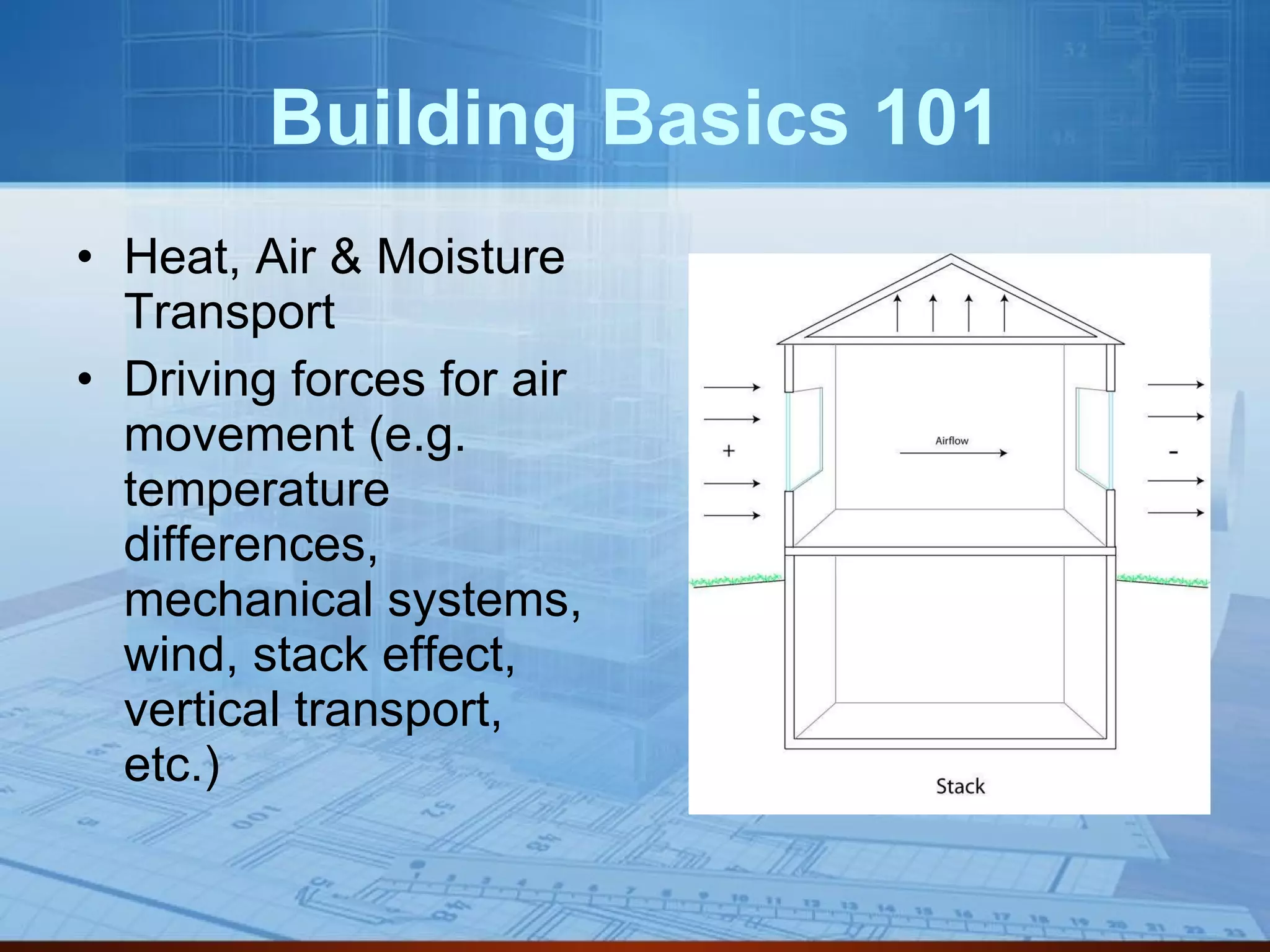

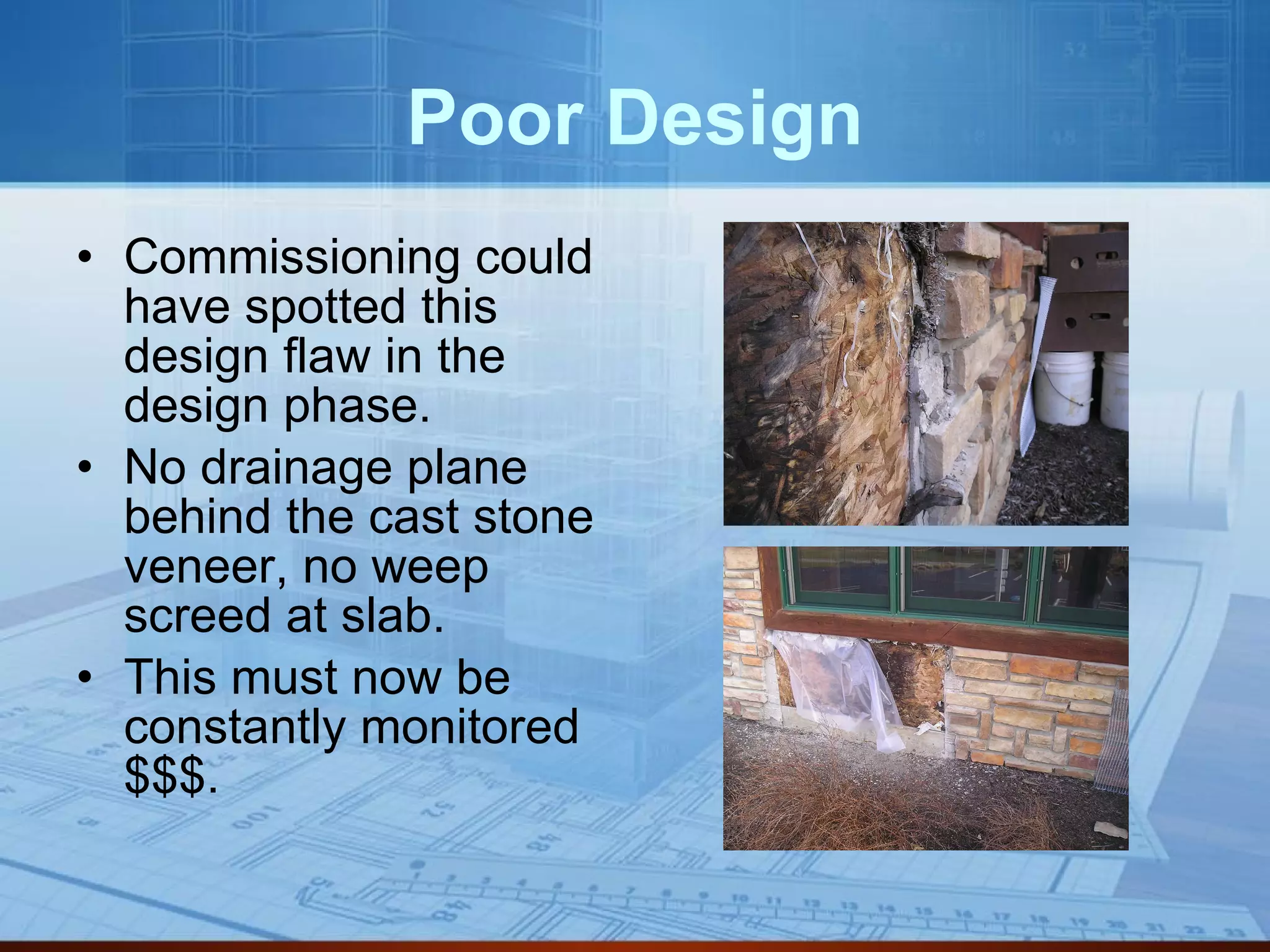

The document discusses the benefits of total building commissioning (TBCx) over traditional commissioning approaches that focus only on mechanical systems. TBCx provides integrated commissioning of all building systems to ensure they are planned, designed, installed and functioning properly as an integrated whole. It can prevent moisture and thermal issues, improve energy efficiency and indoor environment quality, and avoid costly repairs down the line by identifying design and installation flaws during the commissioning process. The document emphasizes the importance of an owner's project requirements document to define benchmark criteria for evaluating the success of the building project.

![Call Us to Discuss Your Requirements 440-946-7191 Email: [email_address] Web: www.cligroup.net](https://image.slidesharecdn.com/tbcx-12836770122577-phpapp01/75/Tb-Cx-21-2048.jpg)