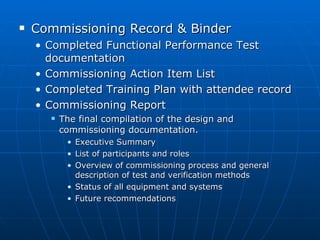

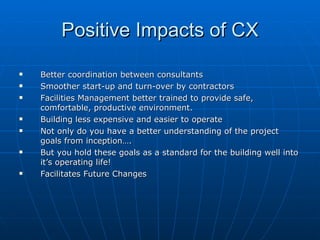

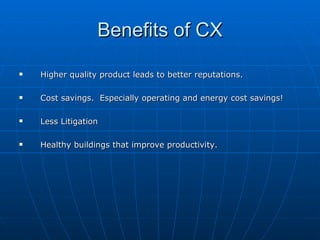

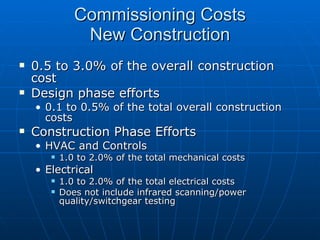

Building commissioning is a systematic process that ensures building systems function as intended throughout their operational life, utilizing a total quality management approach to reduce costs and improve performance. It involves pre-functional checklists, functional testing, and the creation of comprehensive documentation, aiming to enhance coordination, training, and the operational efficiency of the building. Overall, commissioning contributes to higher quality buildings, cost savings, and improved productivity while incurring a percentage of the overall construction costs.