This document provides an introduction to robotics, including:

- Defining robots and discussing their history from the 1920s concept to modern industrial uses

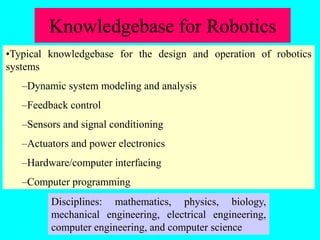

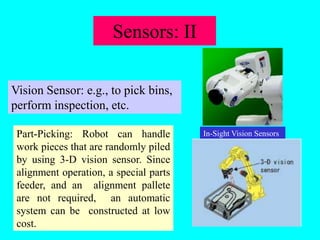

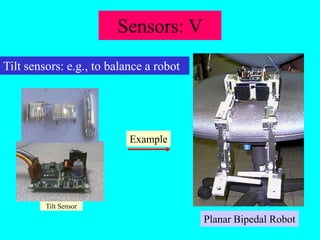

- Describing common robot components like manipulators, sensors, actuators, and controllers

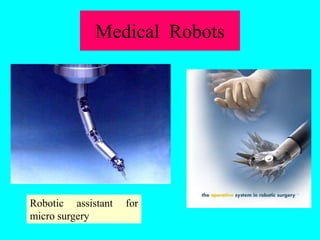

- Explaining what tasks robots can perform like dangerous, repetitive, or menial jobs in various industries

- Discussing future directions like artificial intelligence, autonomy, and humanoid robots