The document discusses the intricacies of virtual commissioning and simulation processes for robotics, focusing on the ABB IRB 6000 robot and associated software tools like Robcad and RRS. It details the iterative updates to the software, motion planning capabilities, and various services available for robotic simulation and programming, emphasizing the benefits of virtual commissioning such as reduced commissioning time and improved product quality. It also outlines the complexity and challenges associated with simulation due to the need for verified documentation and high costs of hardware and software.

![RRS_INITIALIZE

RRS_SET_INITIAL-POSITION

RRS_GET_NEXT_STEP

RRS_SET_OVERRIDE_ACC

[X, Y, Z, Rx, Ry, Rz]

SET_NEXT_TARGET

RCS

RRS](https://image.slidesharecdn.com/virtualcomisionningprocesssimulate-mgurgul-150208044340-conversion-gate02/85/Robotics-Virtual-Commissioning-in-Process-Simulate-8-320.jpg)

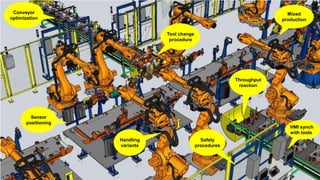

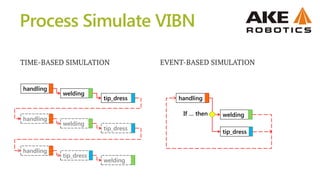

![welding

tip_dress

handling

handling_end

welding_end

tip_dress_end

Transitions conditions

handling

Signal

value

t[s]

0

1

Connections in Gantt Chart

don’t determine operations

executing order!

CEE

parts_counter>=20

part on FX](https://image.slidesharecdn.com/virtualcomisionningprocesssimulate-mgurgul-150208044340-conversion-gate02/85/Robotics-Virtual-Commissioning-in-Process-Simulate-21-320.jpg)

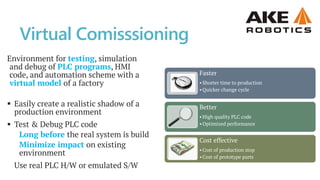

![• Simulation is very complex and require 100% verified documentation.

[mechanical CAD data, ePlan, cycle time diagrams].

• Expensive H/W equipment to run the simulation tools, along with the cost

of licenses.

• Process simulation software is not ready for full VC, many open issues and

bugs on the software.

Cons](https://image.slidesharecdn.com/virtualcomisionningprocesssimulate-mgurgul-150208044340-conversion-gate02/85/Robotics-Virtual-Commissioning-in-Process-Simulate-27-320.jpg)

![Hemming

nhOffsRoller := [[0.015,10.2,-17.5],OrientZYX(0.00,0.00,9.9907)];

GHO := [[0,0,0],[0,0,0],[0,0,0]];

NHsetHO 10, 0, 0, 0, 0, 0, -10, 20;

MoveJ NHTarget(f57_area4,HO{10}),v2500,z10,t_r2_cl,WObj:=wobj_15FX16;

! Spot lsp195621_f57;

VP_SpotL lsp195621_f57,Id_03, vmax, t_Gun1_varioWobj:=wobj_22fx16_f57;

!Move VarioPiker Backward

VP_GunOpen 1000;](https://image.slidesharecdn.com/virtualcomisionningprocesssimulate-mgurgul-150208044340-conversion-gate02/85/Robotics-Virtual-Commissioning-in-Process-Simulate-29-320.jpg)